Method for rapidly culturing autotrophic nitrogen removal granule sludge under conditions of low substrate concentration and high ascending velocity

A technology for autotrophic denitrification particles and granular sludge, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of slow growth of anammox bacteria and achieve Shorten the culture time and facilitate the effect of rapid proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

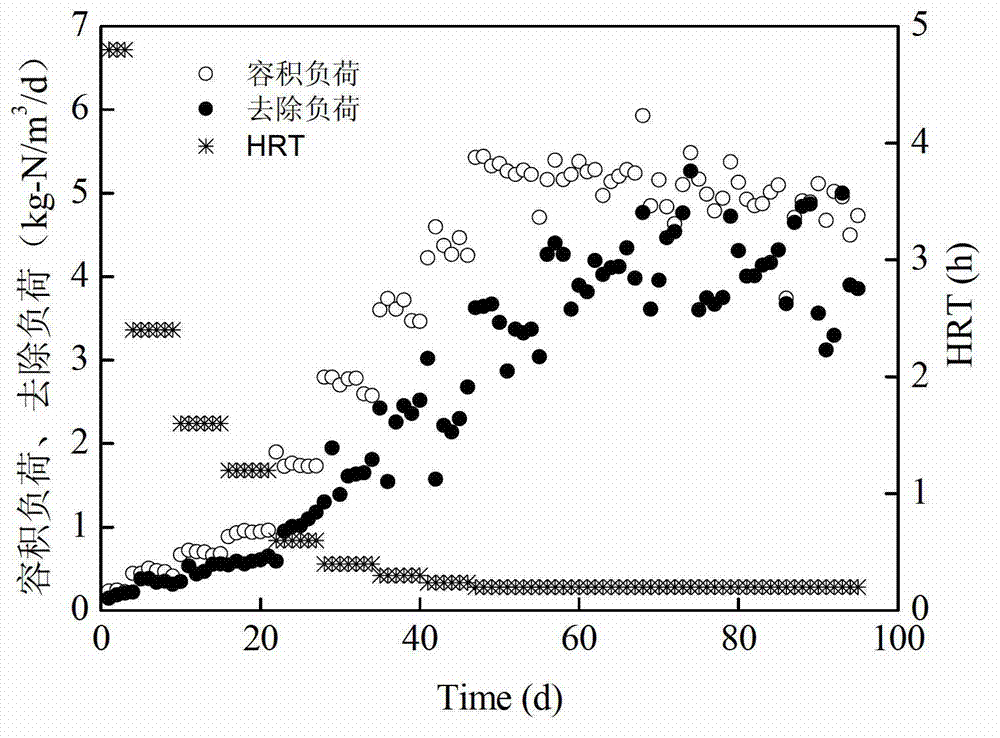

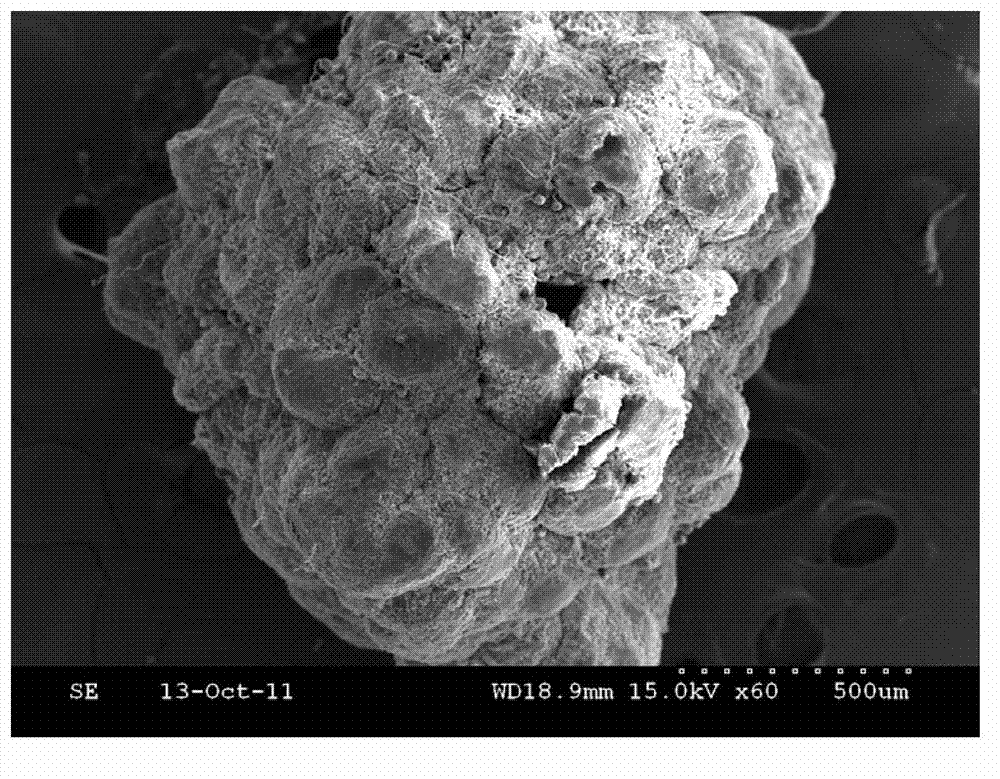

[0022] First, the anaerobic ammonium oxidation granular sludge is crushed and mixed with anaerobic fermentation sludge and aerobic activated sludge according to the mass ratio of 5:75:20. Then the mixed sludge was fed into the upflow anaerobic UASB reactor.

[0023] The reaction zone volume of the anaerobic UASB reactor is 2L, the aspect ratio is (10-20): 1, and is equipped with a constant temperature heating device. The sedimentation area is equipped with a three-phase separator and a sewage return pipe to return the treated sewage to the bottom of the reactor. The reaction area of the reactor is shaded by a shading cloth to avoid the growth of algal substances.

[0024] Artificially synthesized low-ammonia-nitrogen wastewater is used as the influent of the anaerobic UASB reactor, and a small amount of trace elements and inorganic carbon sources are added to ensure the efficient growth and reproduction of autotrophic denitrification bacteria. The concentrations of ammonium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com