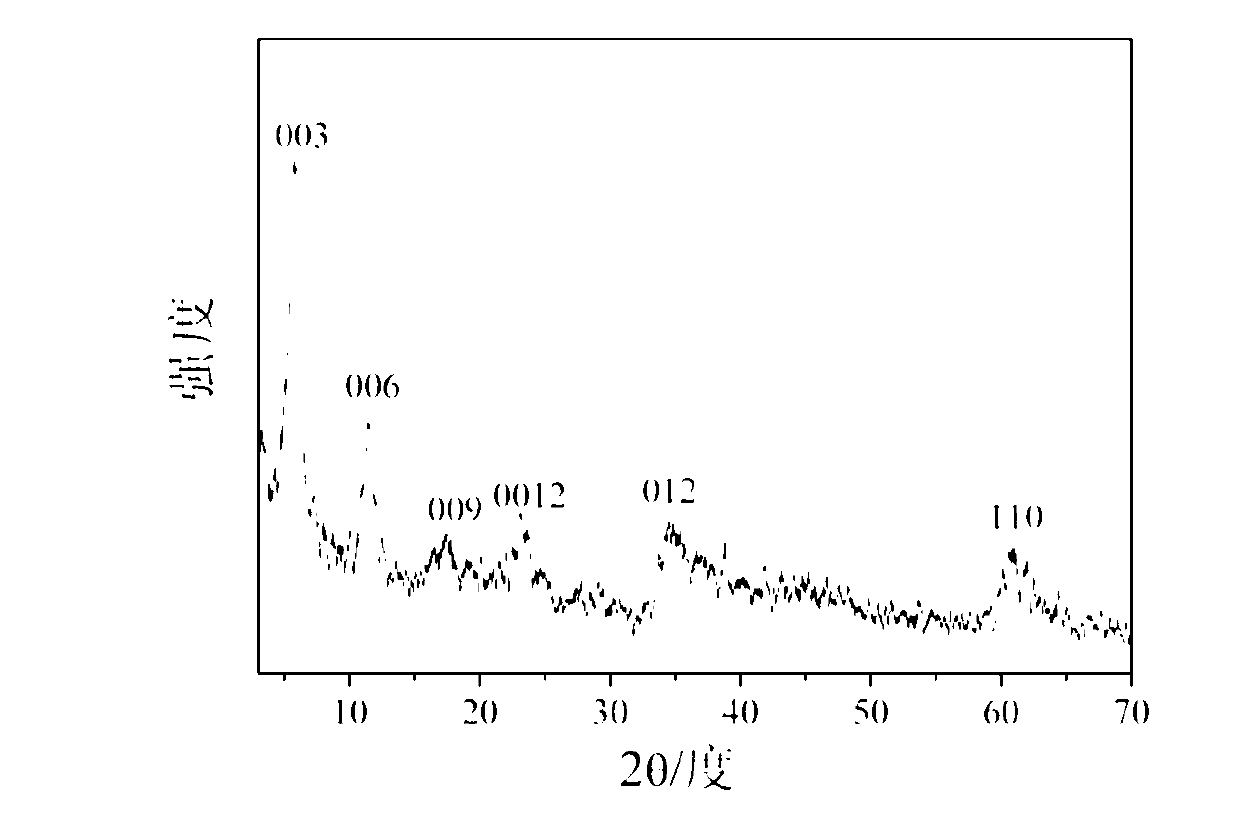

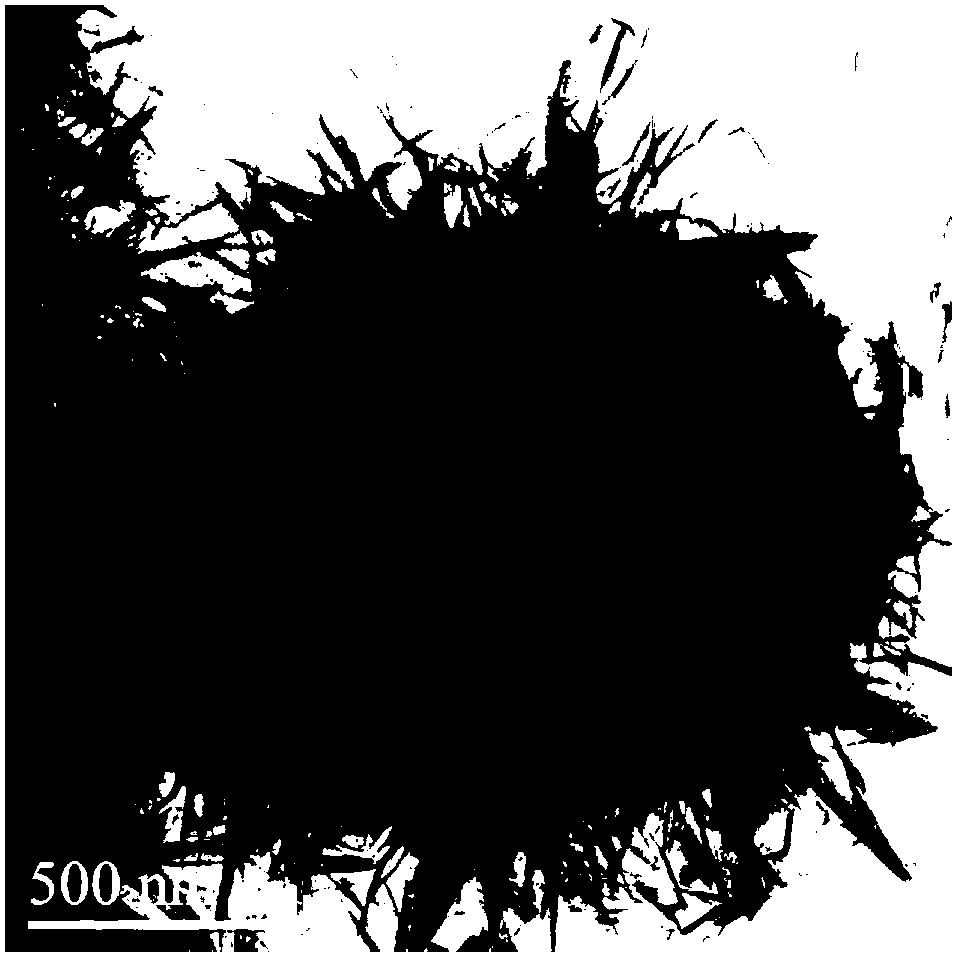

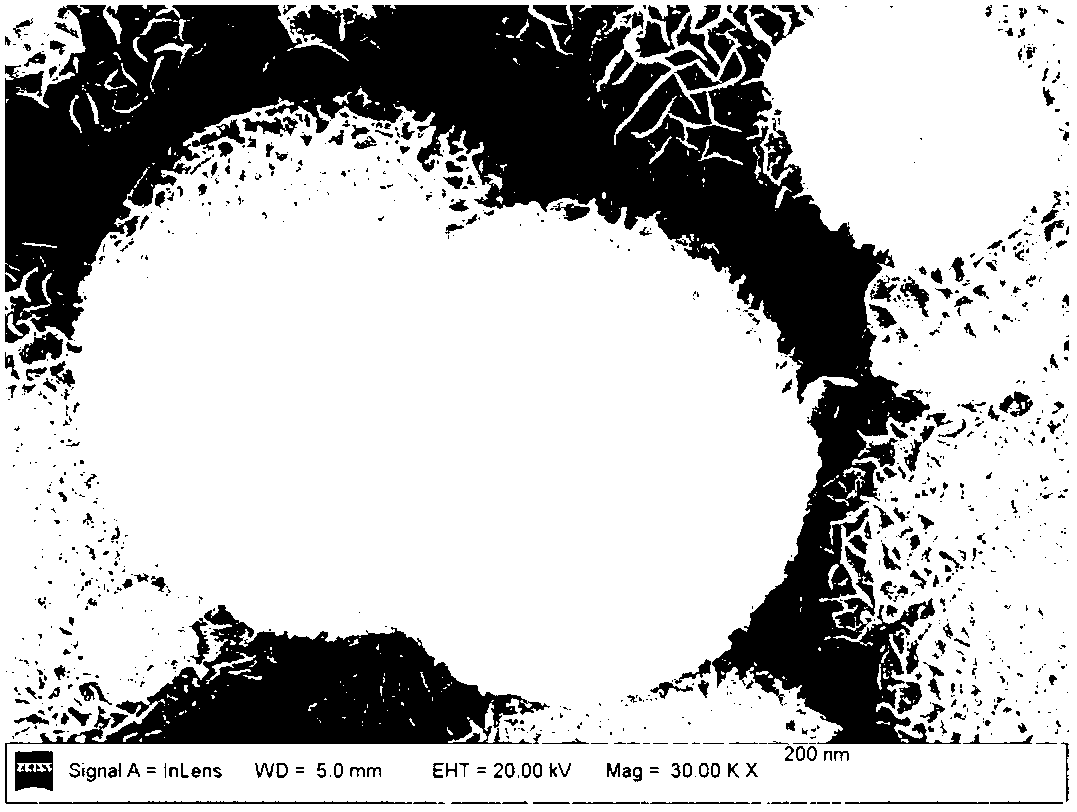

Three-dimensional flower-like salicylic acid radical intercalation layered hydroxide nano material and preparation method thereof

A layered hydroxide, salicylate technology, applied in the preparation of oxide/hydroxide, nickel oxide/nickel hydroxide, nanotechnology, etc. The problems of layered hydroxide nanomaterials and methods are troublesome, and the effects of simple process, high yield and low cost are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A weighs 9.32g of Co(NO 3 ) 2 ·6H 2 O and 3.00g of Al(NO 3 ) 3 9H 2 O was dissolved in deionized water to make 100ml mixed salt solution; 4g of sodium hydroxide was weighed and dissolved in deionized water to make 200ml lye.

[0025] B takes by weighing 12.80g sodium salicylate and dissolves deionized water and is made into 150m sodium salicylate solution, wherein Co(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 The molar ratio of O and sodium salicylate is 4:1:10.

[0026] C. Pour the sodium salicylate solution and the mixed salt solution into a four-neck flask at the same time, and start electric stirring to rotate at a constant speed at 200r / min; after mixing evenly, adjust the pH of the solution to 6.8 with lye.

[0027] D Transfer the mixed solution of step C into a high-pressure hydrothermal reaction kettle with a polytetrafluoroethylene liner, and hydrothermally crystallize at 140°C for 24 hours in a static state; wash the reacted product with deionized water, an...

Embodiment 2

[0029] A weighs 9.32g of Co(NO 3 ) 2 ·6H 2 O and 3.00g of Al(NO 3 ) 3 9H 2 O was dissolved in deionized water to make a 100ml mixed salt solution; 4g of sodium hydroxide was weighed and dissolved in deionized water to make a 200ml alkali solution.

[0030] B takes by weighing 19.20g sodium salicylate and dissolves deionized water and is made into 150m sodium salicylate solution, wherein Co(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 The molar ratio of O and sodium salicylate is 4:1:15.

[0031] C. Pour the sodium salicylate solution and the mixed salt solution into a four-necked flask at the same time, and start electric stirring to rotate at a constant speed at 200r / min; after mixing evenly, adjust the pH of the solution to 7.2 with lye.

[0032]D Transfer the mixed solution of step C into a high-pressure hydrothermal reaction kettle with a polytetrafluoroethylene liner, and hydrothermally crystallize at 120°C for 24 hours in a static state; wash the reacted product with de...

Embodiment 3

[0034] A weighs 7.75g of Ni(NO 3 ) 2 ·6H 2 O and 5.00g of Al(NO 3 ) 3 9H 2 O was dissolved in deionized water to make 100ml mixed salt solution; 4g of sodium hydroxide was weighed and dissolved in deionized water to make 200ml lye.

[0035] B takes by weighing 12.80g sodium salicylate and dissolves deionized water and is made into 150m sodium salicylate solution, wherein Co(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 The molar ratio of O and sodium salicylate is 2:1:8.

[0036] C Pour the sodium salicylate solution and the mixed salt solution into a four-necked flask at the same time, and start electric stirring to rotate at a constant speed at 200r / min; after mixing evenly, adjust the pH of the solution to 7 with lye.

[0037] D Transfer the mixed solution of step C into a high-pressure hydrothermal reaction kettle with a polytetrafluoroethylene liner, and hydrothermally crystallize at 120°C for 24 hours in a static state; wash the reacted product with deionized water, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com