Nano particle reinforced ABS (acrylonitrile butadiene styrene) composite material and preparation method thereof

A technology of nanoparticles and composite materials, applied in the field of nanoparticle-reinforced ABS composite materials and their preparation, to achieve the effects of improving tensile strength and impact strength, improving overall performance and weather resistance, and improving dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] (1) Preparation of surface modified nanoparticles

[0023] Add nanoparticles with an average particle size of 5-100nm, surfactants and organic antioxidants into a high-speed mixer at a mass ratio of 1.0:0.02-0.05:0.02-0.05, and at a temperature of 80-150°C, Stir for 50-100 min, so that the surfactant and the nanoparticles are uniformly dispersed, and the surfactant is coated on the nanoparticles to form surface-modified nanoparticles; the nanoparticles are composed of organic montmorillonite (OMMT), nano Composition of titanium dioxide and nano hydrotalcite (LDH);

[0024] (2) Preparation of ABS composite materials

[0025] The surface-modified nanoparticles, ABS resin and ethylene-octene copolymer (POE) are added into the twin-screw extruder according to the mass ratio of 1.0-5.0:24-45:0-10.0, and the extrusion temperature is 210-235°C, the screw speed is 100-210 rpm, and the nano-particle reinforced ABS composite material is obtained after extrusion and granulation....

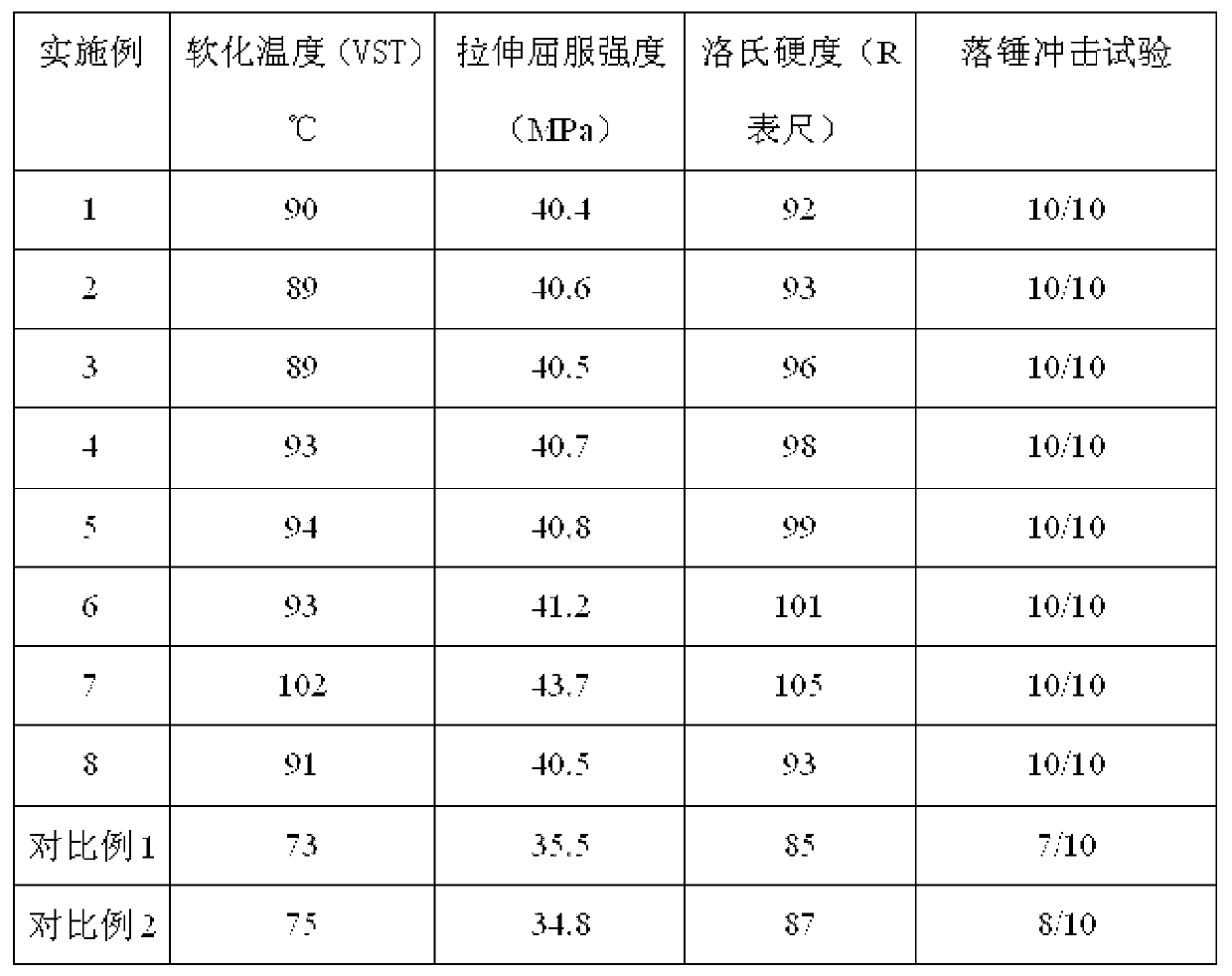

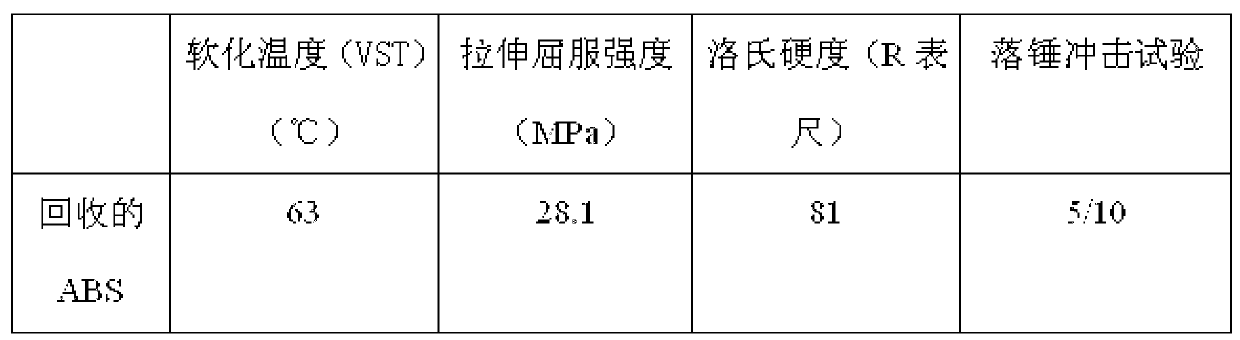

Embodiment 1

[0031] Add nanoparticles with an average particle size of 5-100nm, oleic acid and antioxidant BHT into a high-speed mixer at a mass ratio of 1.0:0.02:0.02, and stir for 50-100 min at a temperature of 100-120°C , forming surface-modified nanoparticles; the nanoparticles are composed of 40wt% OMMT, 30wt% nano-titanium dioxide, and 30wt% LDH; then surface-modified nanoparticles and reclaimed ABS are added according to a mass ratio of 1:15 Melt blending in a twin-screw extruder, where the extrusion temperature is 210-235°C, the screw speed is 120-150 rpm, and the nanoparticle-reinforced ABS composite material is obtained after extrusion granulation, and its properties are shown in Table 1.

Embodiment 2

[0033] Add nanoparticles with an average particle size of 5-100nm, oleic acid and antioxidant BHT into a high-speed mixer at a mass ratio of 1.0:0.05:0.02, and stir for 75-100 min at a temperature of 120-150°C , forming surface-modified nanoparticles; the nanoparticles are composed of 50wt% OMMT, 25wt% nano titanium dioxide, and 25wt% LDH; then surface-modified nanoparticles and reclaimed ABS1 are added according to a mass ratio of 1:10 Melt blending in a twin-screw extruder, where the extrusion temperature is 210-235°C, the screw speed is 120-150 rpm, and the nanoparticle-reinforced ABS composite material is obtained after extrusion granulation, and its properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com