Agaricus bisporus casing material and preparation method thereof

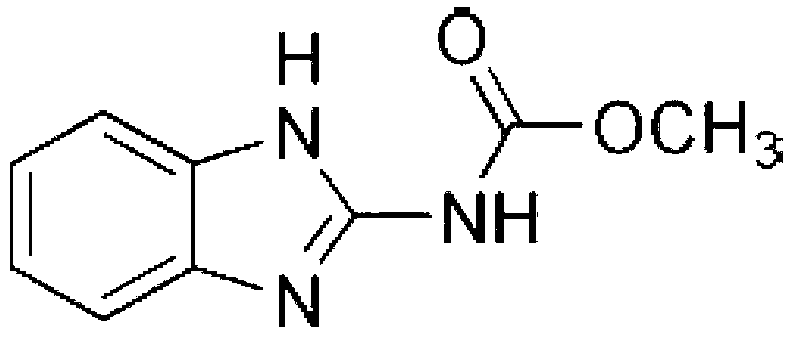

A technology of soil covering materials and production methods, which is applied to fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of soil covering materials of Agaricus bisporus that have not been seen yet, achieve significant economic and ecological benefits, simple production, and reduce usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

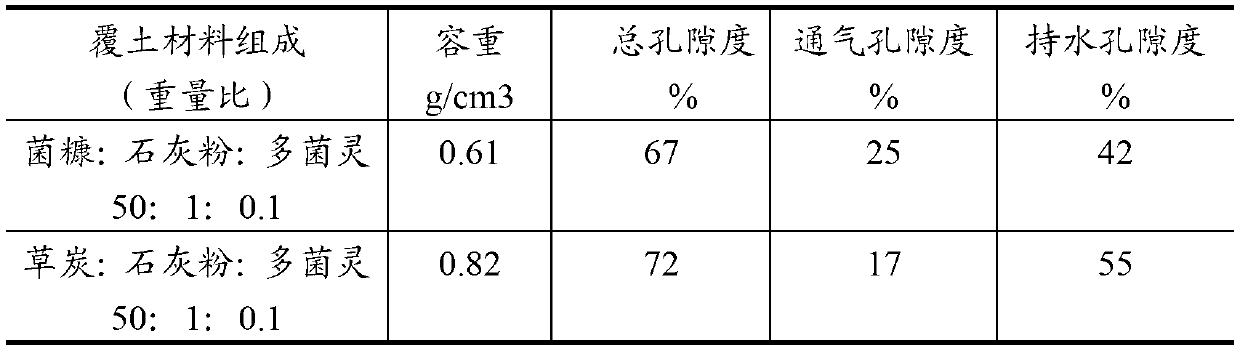

[0053] Embodiment 1: the production of Agaricus bisporus soil-covering material

[0054] Raw materials: fungus chaff from Yongledian, Tongzhou District, Beijing; peat from Jilin Province, China; ordinary soil from Tongzhou, Beijing.

[0055] The implementation steps of this embodiment are as follows:

[0056] A. Mature chaff

[0057] After crushing the waste bacteria sticks, add pig manure to make the C / N ratio 25:1, then add water to make the water content 60% by weight, and then pile it into a pile with a width of 1.6 meters and a height of 1.0 meters. Drill holes from top to bottom in the stockpile, the diameter of the holes is 5cm, and the hole distance is 15cm. When the central temperature of the pile body reaches 65°C, the turning of the pile is repeated until the central temperature of the pile body is close to the ambient temperature, and the described Mushroom chaff;

[0058] B. Preparation of bisporus covered with soil

[0059] Let the fungus chaff and peat obtai...

Embodiment 2

[0061] Embodiment 2: the production of Agaricus bisporus soil-covering material

[0062] Raw materials: fungus chaff from Yongledian, Tongzhou District, Beijing; peat from Jilin Province, China; ordinary soil from Tongzhou, Beijing.

[0063] The implementation steps of this embodiment are as follows:

[0064] A. Mature chaff

[0065] After crushing the waste bacteria sticks, add cow dung to make the C / N ratio 30:1, then add water to make the water content 62% by weight, and then pile it into a pile with a width of 1.5 meters and a height of 1.1 meters. Drill holes from top to bottom in the stockpile, the diameter of the holes is 6cm, and the hole distance is 16cm. When the central temperature of the heap reaches 65°C, the turning of the heap is repeated until the central temperature of the heap is close to the ambient temperature, and the described Mushroom chaff;

[0066] B. Preparation of bisporus covered with soil

[0067] Let the decomposed fungus chaff and ordinary so...

Embodiment 3

[0069] Embodiment 3: the production of Agaricus bisporus soil-covering material

[0070] Raw materials: fungus chaff from Yongledian, Tongzhou District, Beijing; peat from Jilin Province, China; ordinary soil from Tongzhou, Beijing.

[0071] The implementation steps of this embodiment are as follows:

[0072] A. Mature chaff

[0073] After the waste bacteria sticks are crushed, add urea to make the C / N ratio 26:1, then add water to make the water content 55% by weight, and then pile them into a pile with a width of 1.6 meters and a height of 1.2 meters. The stockpile is punched from top to bottom, the diameter of the holes is 7cm, and the hole distance is 18cm. When the central temperature of the pile reaches 65°C, the turning is repeated until the central temperature of the pile is close to the ambient temperature, and the bacterial Bran decomposing;

[0074] B. Preparation of bisporus covered with soil

[0075] Let the fungus chaff and peat obtained in step A) pass throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com