Method and apparatus for constructing three-dimensional microenvironment

A microenvironment, three-dimensional technology, applied in enzymology/microbiology devices, biochemical cleaning devices, biochemical equipment and methods, etc., can solve problems such as reducing the total cost of research, and achieve easy operation, wide application, and broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

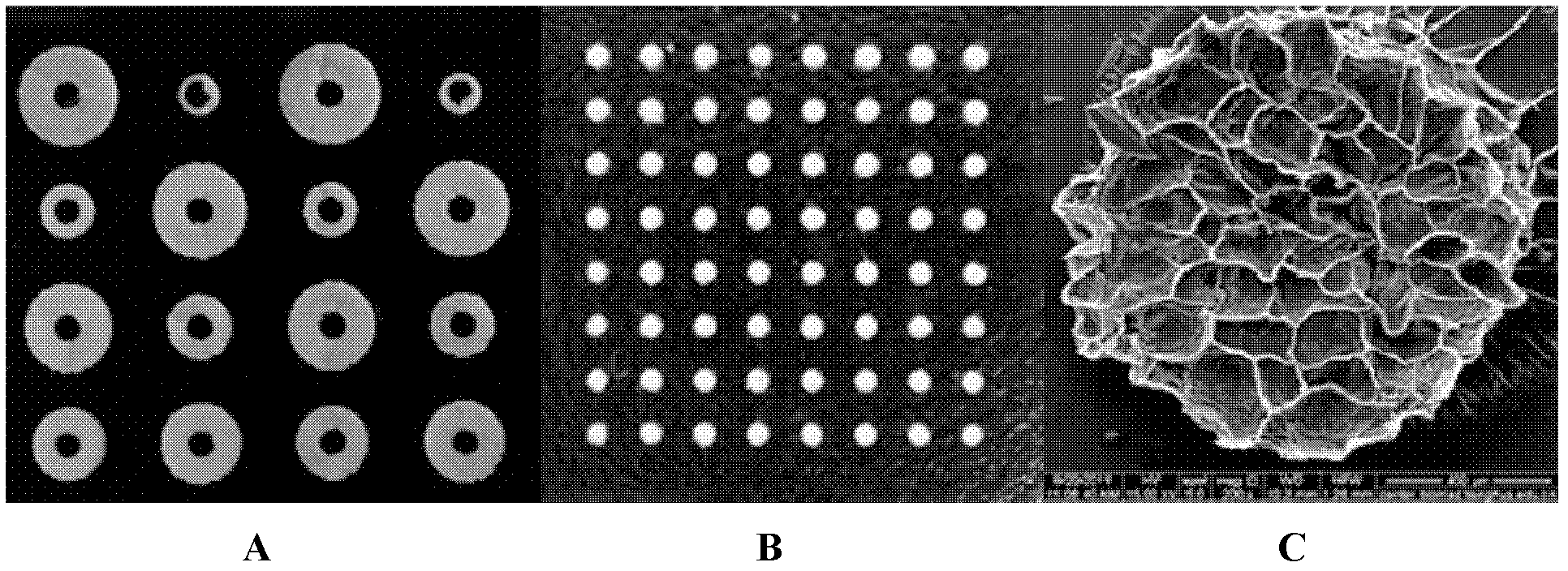

[0059] The preparation of the microsponge scaffold display involves various pattern manufacturing and microfabrication techniques including photolithography, microcontact printing, microfluidic patterning, Laminar flow patterning, stencil patterning, Imprint lithography, flow lithography, etc. The above-mentioned technologies have their own advantages and disadvantages in the production process, and they can be used in combination with other technologies to achieve a better three-dimensional patterning effect. For example, in photolithography, using a digital micromirror device (digital micromirror device DMD) instead of a photomask can dynamically change the pattern during the production process, thereby producing a three-dimensional pattern with high complexity and high internal correlation. The selection of pattern manufacturing, micro-manufacturing technology and combined use technology needs to comprehensively consider the physical and chemical properties of materials and...

Embodiment 1

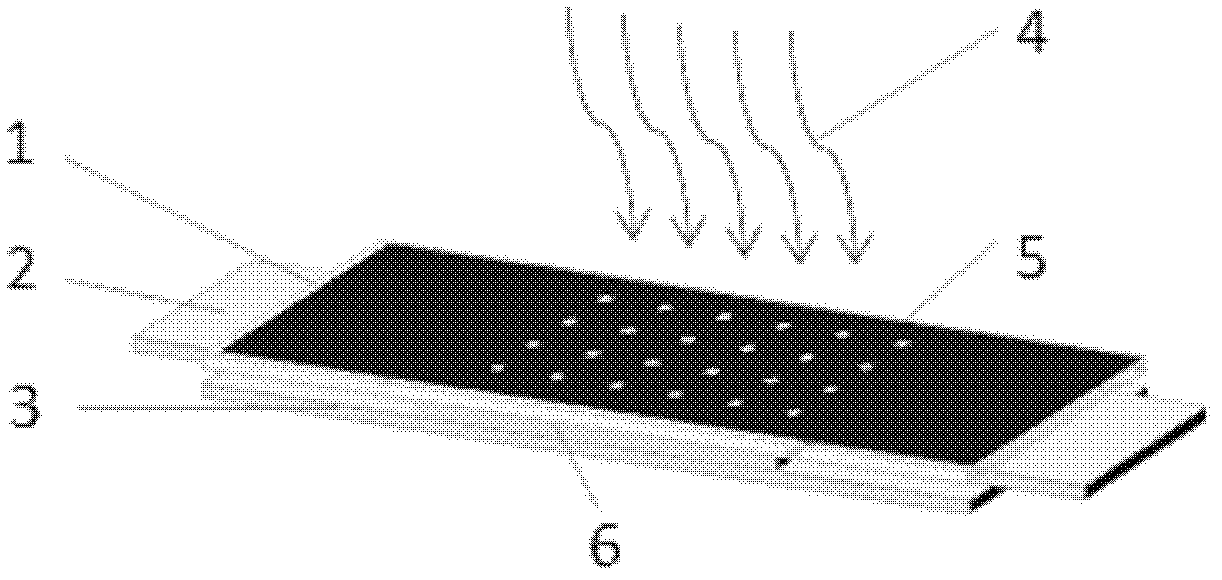

[0079] Embodiment 1, the manufacture of the device for constructing three-dimensional microenvironment

[0080] 1. Combining photolithography, salting-out technology and freeze-drying method to prepare microsponge scaffold display

[0081] The biological material for preparing the microsponge scaffold display provided in this example is the monomer polyethylene glycol diacrylate (PEGDA4000).

[0082] The polyethylene glycol diacrylate selected in this example has the advantages of good biocompatibility, mechanical properties, non-degradability, and controllability of the degree of photocrosslinking, and is suitable as a biomaterial for the preparation of microsponge scaffolds in this example. . The slide glass and cover glass used in the display process of preparing the microsponge holder with supporting base B are commercial slide glass and cover glass, wherein the size of the slide glass is 76.2mm×25.4mm, and the thickness of the cover glass is is 150 μm.

[0083] The fab...

Embodiment 2

[0133] Example 2. Utilizing the device provided by the present invention to realize three-dimensional microscale efficient loading of sample liquid

[0134] Utilize the device prepared in embodiment 1 (the microsponge support array is figure 2 The microsponge support array shown in B, on which the volume of the microsponge support is 0.2355μl) realizes the efficient three-dimensional microscale loading of the sample solution, and the schematic diagram of the process is shown in Figure 4 . The liquid thin-layer substrate is covered on the display of the micro-sponge bracket, and the liquid is automatically sucked into the micro-sponge bracket by using the adsorption of the micro-sponge and the easy-flowing separation of the liquid thin layer, so as to realize the three-dimensional micro-scale loading of the sample liquid. The sample solution can be any one or a mixture of small molecular compounds, drugs, nucleic acids, proteins, extracellular matrix components, polymer mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com