Molybdenum plate nickel plating method for silicon power electronic device

A technology for power electronic devices and molybdenum sheets is applied in the field of semiconductor devices, which can solve the problems of poor environmental protection, failure to meet thickness requirements, and restriction on the thickness of nickel-plated nickel layers, and achieves the effects of convenient operation and easy control of the thickness of nickel-plated layers of molybdenum sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

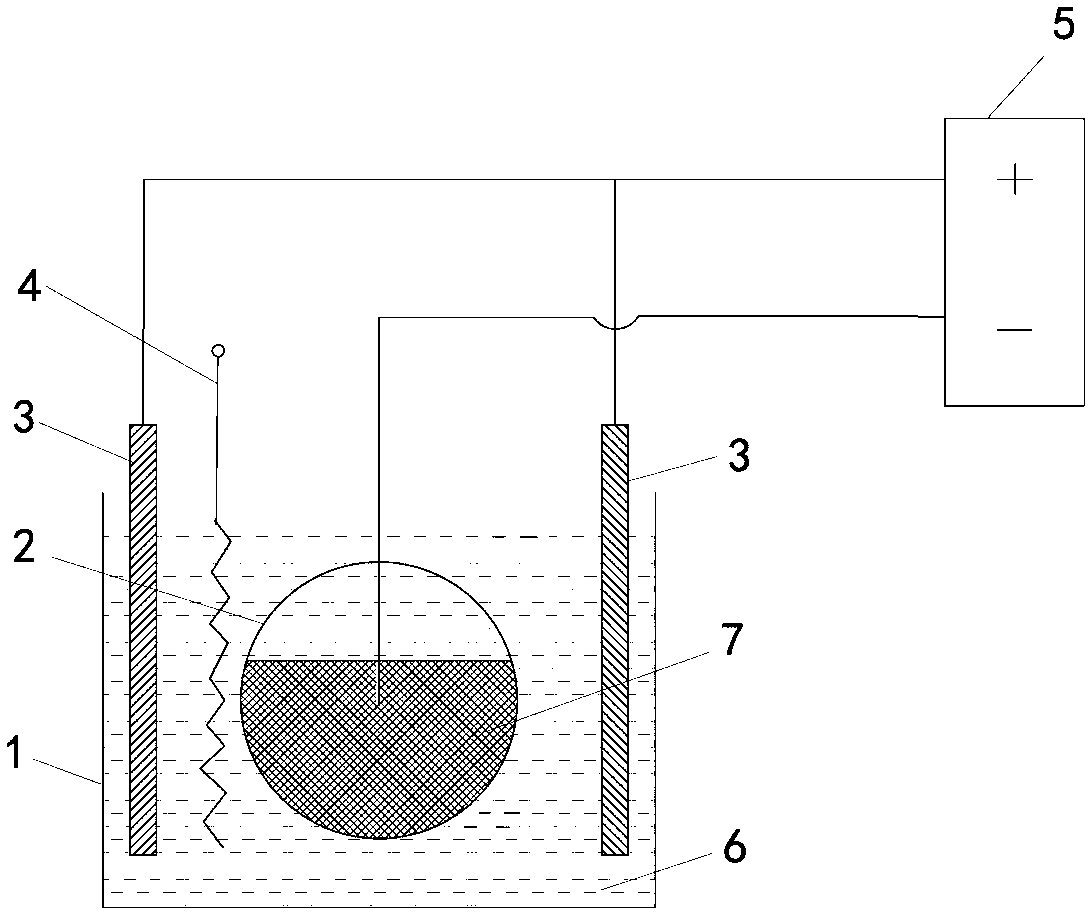

[0009] Description of drawings: electroplating tank 1, drum 2, metal nickel plate 3, electric heating tube 4, electroplating power supply 5, plating solution 6, molybdenum sheet 7.

[0010] Such as figure 1 Shown, a kind of nickel-plating method of molybdenum sheet of silicon power electronic device is that described molybdenum sheet 7 is put into cylinder 2 and is immersed in the plating bath together and is barrel-plated, and nickel sulfate 250g / L, nickel chloride 50g / L are contained in the plating bath. L, boric acid 45g / L and magnesium sulfate 20g / L; the temperature of the plating solution is 40-55°C, the pH value is 8-9, the rotating speed of the drum 2 is 10-15 rpm, and the anode of the electroplating power supply is connected to the electroplated metal nickel plate 3 , the anode current is 80-90A, the cathode is introduced into the drum to contact the molybdenum sheet, and the electroplating time is 40-60 minutes; the molybdenum sheet 7 is nickel-plated once, poured out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com