Method for manufacturing nanofluid channel of integrated scaleplate based on flexible template

A technology integrating scale and nanofluid, applied in nanotechnology, photolithography process of pattern surface, optics, etc., can solve the problems of hard template not being well fitted, imprinting structure distortion, deforming hard template, etc. , to achieve the effect of facilitating large-area imprinting and demoulding, small demoulding force, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

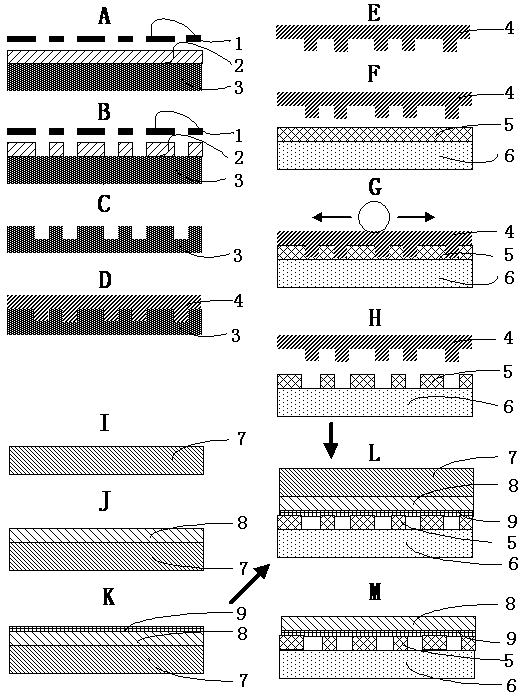

[0033] like figure 1 and figure 2 As shown, the fabrication method of the nanofluidic channel with integrated ruler based on the flexible template operates as follows:

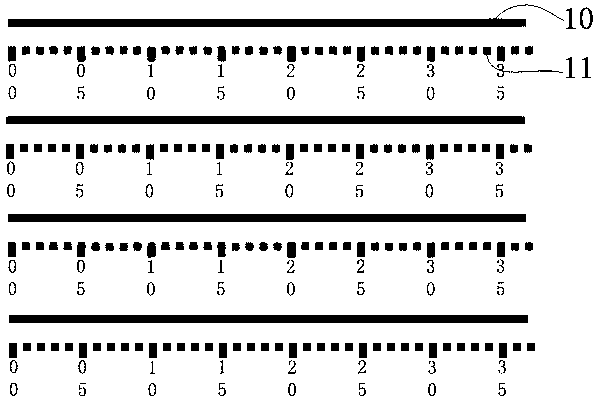

[0034] a. The photolithography mask 1 including the grating line structure 10 and the digital scale structure 11 is fabricated by an electron beam method;

[0035] b. Spin-coat AZ1350 photoresist 2 on the quartz template 3, such as figure 1 As shown in the middle A, the grating line structure 10 and the digital scale structure 11 on the photolithography mask 1 are fabricated on the photoresist 2 by optical photolithography, as shown in Fig. figure 1 Shown in B; then by reactive ion etching, the grating line structure and digital scale structure on the photoresist 2 are transferred to the quartz template 3 to form a quartz template 3 with a grating line structure and a digital scale structure, as shown in figure 1 shown in C;

[0036] c. Cast the PDMS viscous liquid onto the quartz template 3, such as ...

Embodiment 2

[0043] like figure 1 and figure 2 As shown, the fabrication method of the nanofluidic channel with integrated ruler based on the flexible template operates as follows:

[0044] a, with embodiment one;

[0045] b, with embodiment one;

[0046] c, with embodiment one;

[0047] d. The quartz piece was ultrasonically treated with acetone for 5 minutes, rinsed with deionized water and dried, then baked at 150°C for 10 minutes and cooled naturally; spin-coat SU-8 photoresist 5 on the surface of the quartz piece, and bake at 100°C for 10 minutes forming a quartz substrate 6;

[0048] e. The PDMS stamp 4 and the quartz substrate 6 produced in step c are stacked and arranged in an orderly manner, such as figure 1 As shown in F, preheat at 100°C for 5 min to soften the SU-8 photoresist 5 on the surface of the quartz substrate 6, use a PDMS flexible rod to roll to the PDMS stamp 4 and apply 1MPa imprinting pressure to exclude the PDMS stamp 4 and SU-8 The air between the photore...

Embodiment 3

[0053] like figure 1 and figure 2 As shown, the fabrication method of the nanofluidic channel with integrated ruler based on the flexible template operates as follows:

[0054] a, with embodiment one;

[0055] b, with embodiment one;

[0056] c, with embodiment one;

[0057] d. The quartz piece was ultrasonically treated with acetone for 5 minutes, rinsed with deionized water and dried, then baked at 130°C for 20 minutes, and cooled naturally; spin-coat SU-8 photoresist 5 on the surface of the quartz piece, and bake at 90°C for 15 minutes forming a quartz substrate 6;

[0058] e. The PDMS stamp 4 and the quartz substrate 6 produced in step c are stacked and arranged in an orderly manner, such as figure 1 As shown in F, preheat at 90°C for 10 min to soften the SU-8 photoresist 5 on the surface of the quartz substrate 6, use a PDMS flexible rod to roll to the PDMS stamp 4 and apply 2MPa imprinting pressure to exclude the PDMS stamp 4 and SU-8 The air between the photore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spin coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com