Method and device for capturing carbon dioxide in flue gas of power station boiler

A carbon dioxide and power plant boiler technology, which is applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems that limit the large-scale carbon capture application of CCS technology, unstable operation, and large water consumption, so as to improve energy utilization High efficiency, stable and reliable operation, and the effect of reducing system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] 1. Device

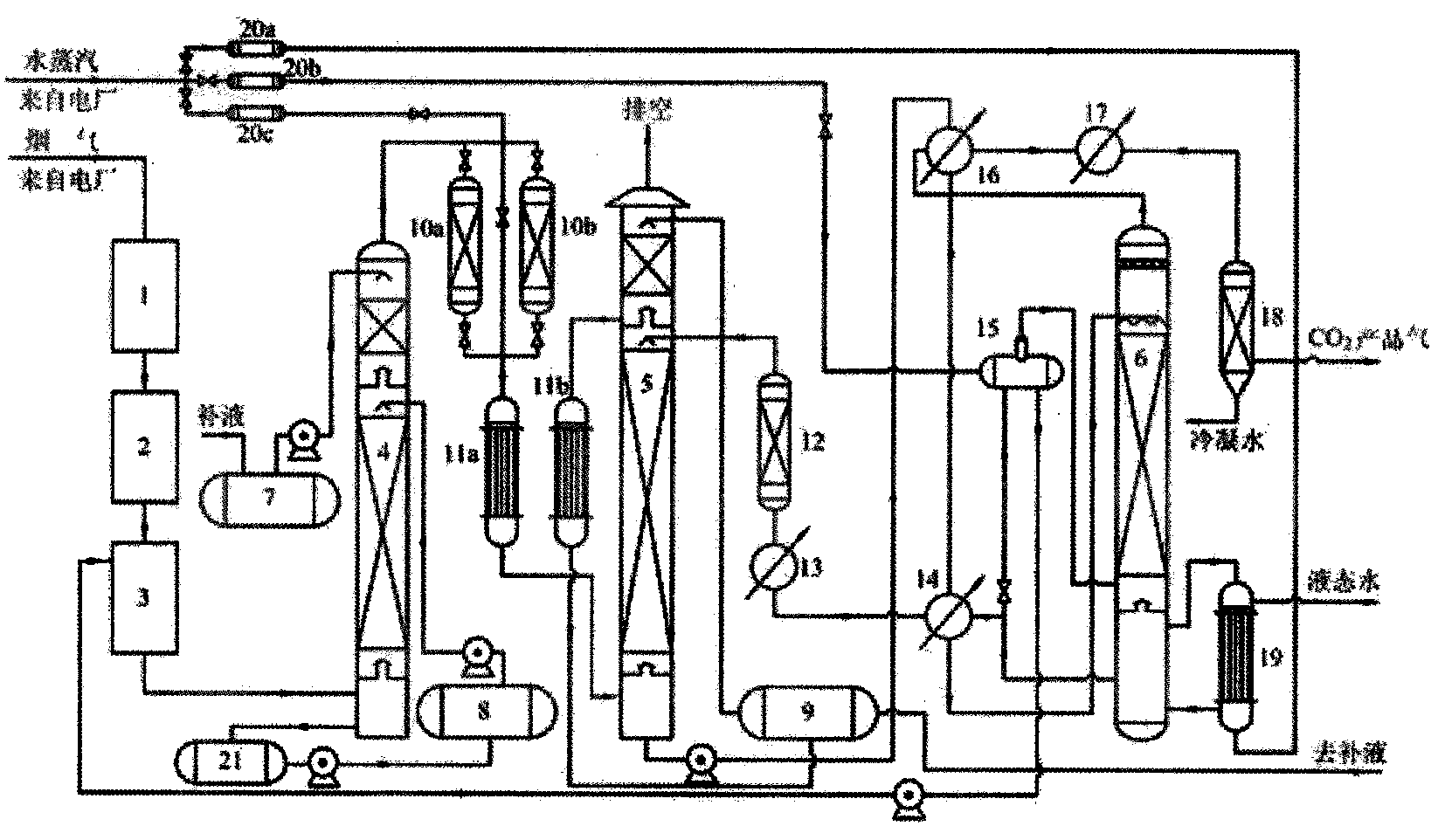

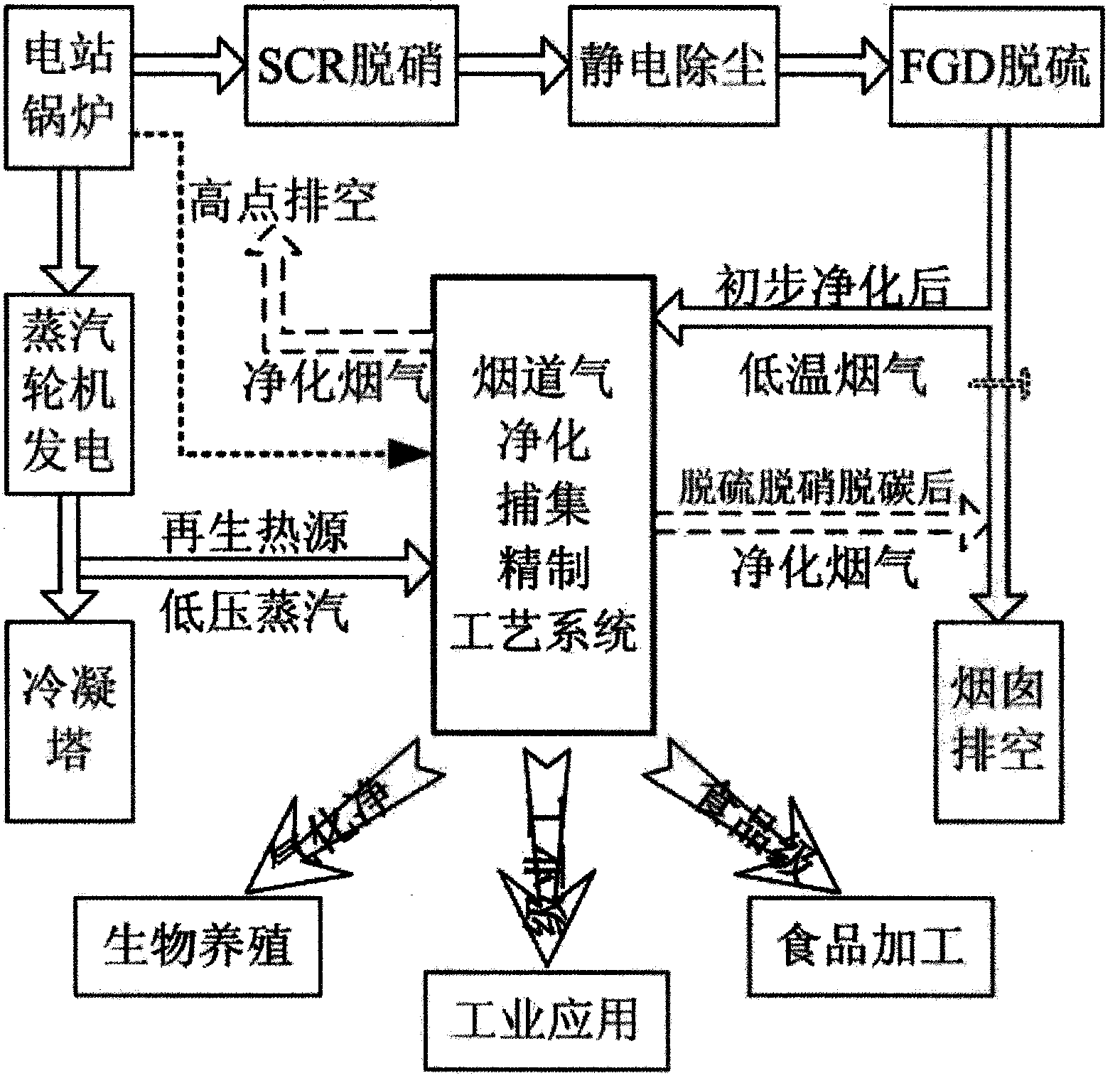

[0045] figure 1 The schematic diagram of the carbon dioxide capture device in the power plant boiler flue gas provided by the present invention includes a purification system, which includes a denitrification system 1 , a dust removal system 2 and a desulfurization system 3 connected in sequence. The outlet end of the desulfurization system 3 is connected to the bottom of a desulfurization and denitrification water washing tower 4. The upper part of the desulfurization and denitrification water washing tower 4 is provided with a washing section, and the upper part of the water washing section is connected to the washing liquid storage tank 7 through a pump. The bottom of the desulfurization and denitrification water washing tower 4 is also connected to a regeneration tank 21. The regeneration tank 21 is connected to the desulfurization and denitration solution storage tank 8 through a pump, and the desulfurization and denitration solution storage tank 8 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com