Aliphatic-aromatic copolyester and preparation method thereof

An aromatic and aliphatic technology, applied in the field of aliphatic-aromatic copolyester and its preparation, can solve problems that cannot meet real life, achieve excellent melt strength, tear resistance and impact resistance, and improve aging resistance Performance, the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Add 100 g of nano titanium dioxide to 0.1 g of isopropyl tris(dioctyl phosphate acyloxy) titanate, heat to 30° C., stir at high speed for 1 minute, and ultrasonically treat for 3 minutes to prepare surface-treated nano titanium dioxide.

[0049] 146g 1,6-adipic acid, 166g terephthalic acid, 270g 1,4-butanediol, placed in a 1000ml flask, add 0.03g antimony trioxide catalyst, 0.05g tetraisopropyl titanate, and add it to the surface The treated nano-particle titanium dioxide 0.003g and nano-alumina 0.001g are esterified at 130°C to 240°C. After the esterification rate reaches 95% under normal pressure, the polycondensation reaction is carried out, and the polycondensation reaction is carried out at 200-280°C under vacuum. , Discharge after reaching a certain viscosity.

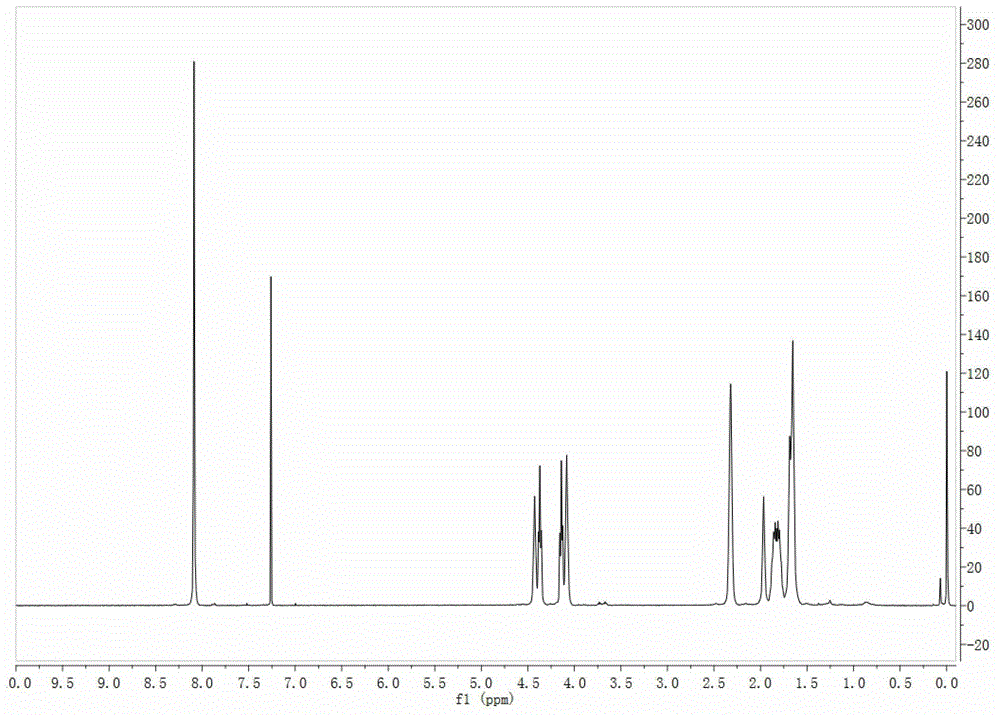

[0050] figure 1 This is the 1H NMR spectrum of the product of Example 1.

Embodiment 2

[0052] Add 100g of nano silica, add 0.5g of γ-glycidoxypropyltrimethoxysilane, 9g of phosphate acyloxyisooctanol aluminate, heat to 80°C, stir at high speed for 15 minutes to prepare a surface-treated Nano silica.

[0053] 182g 1,6-adipyl chloride, 19.4g dimethyl terephthalate, 100g ethylene glycol, 20g polyethylene glycol with a molecular weight of 400, placed in a 1000ml flask, add 0.1g of antimony trioxide catalyst, add 16g of surface-treated nano-particle silica, undergo esterification reaction at 130°C to 240°C, negative pressure, absolute pressure of 70kPa, and esterification rate of 95%, then proceed to polycondensation reaction. The polycondensation reaction is 200~ It is carried out at 280°C, and the material is discharged after reaching a certain viscosity.

Embodiment 3

[0055] Add 100g of nano hydrotalcite, add 0.5g of γ-glycidyloxypropyltrimethoxysilane, 1g of distearoyloxyisopropyl aluminate, heat to 80℃, stir at low speed for 40 minutes to prepare surface treated nano Hydrotalcite.

[0056] 73g 1,6-dimethyl adipate, 166g terephthalic acid, 360g 1,4-butanediol, placed in a 1000ml flask, add 0.02g of the catalyst germanium oxide, carry out the esterification reaction at 130℃ to 260℃, The absolute pressure is 150KPa normal pressure, and the esterification rate reaches 95%, 2.5g of surface-treated nano-particle hydrotalcite is added, and the polycondensation reaction is carried out. The polycondensation reaction is carried out at 200-280°C under vacuum to reach a certain viscosity After discharging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com