Hydrophilic reverse osmosis composite membrane and preparation method thereof

A reverse osmosis composite membrane and hydrophilic polymer technology, applied in the field of membrane separation, can solve the problems of poor hydrophilicity and low anti-pollution ability, and achieve the effects of not easy to lose, improve anti-pollution ability, and high desalination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The preparation process of the porous polysulfone support layer in this embodiment is as follows:

[0069] Prepared according to conventional methods, will contain 18.5% (weight percent) of polysulfone, 11.5% (weight percent) of ethylene glycol monomethyl ether, 0.03% (weight percent) of sodium dodecylsulfonate, 66.97% (weight percent) percent) of N,N-dimethylformamide casting liquid coating scraped on the polyester non-woven fabric, immerse it in deionized water at room temperature for phase inversion, remove the good solvent, and obtain a molecular weight cut-off of 20000-50000 The porous polysulfone support layer was stored in deionized water until use.

Embodiment 1

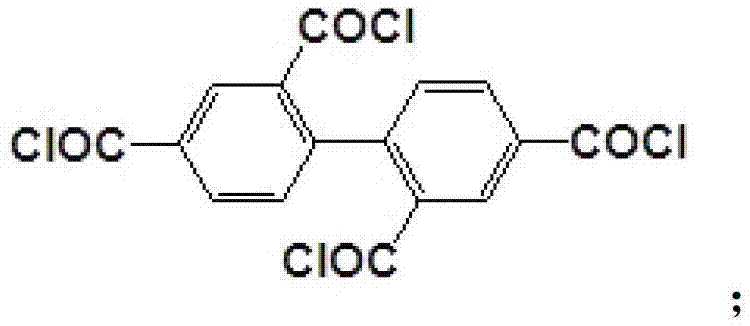

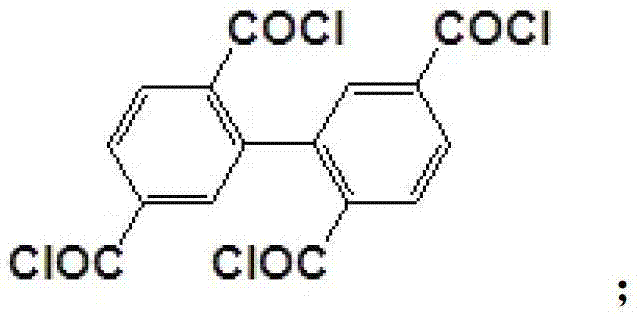

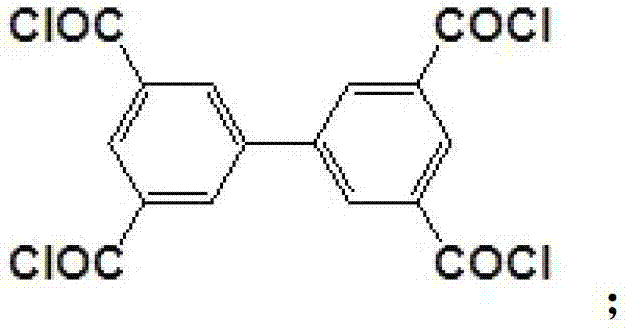

[0071] Example 1 Preparation of reverse osmosis composite membrane covalently grafted with polyethylene glycol 2000 on the surface by m-phenylenediamine and 2,2',5,5'-biphenyltetrayl chloride

[0072] Step 1. Evenly pour the aqueous solution of m-phenylenediamine with a mass volume concentration of 2.0g / 100mL on the surface of the porous polysulfone support layer with a molecular weight cut-off of 20,000 in wet state, cover for 1 minute, pour to remove excess amine liquid, and air dry Dry for 1 minute to obtain a porous polysulfone support layer whose surface is covered with m-phenylenediamine aqueous solution;

[0073] Step 2, pour the mixed solution of IsopaG and toluene of 2,2′,5,5′-biphenyltetrayl chloride with a mass volume concentration of 0.2g / 100mL evenly on the surface of the porous polysulfone support layer obtained in step 1, and carry out Interfacial polymerization reaction for 20 seconds to obtain a composite membrane covered with an active separation layer;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com