Carbon fiber reinforced pantograph carbon slide plate material and manufacturing method thereof

A pantograph carbon sliding plate and carbon fiber technology, applied in the field of electric locomotives, can solve the problems of unstable product performance, high defective rate, performance degradation, etc., and achieve the effects of large-scale production, stable product performance and simple manufacturing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

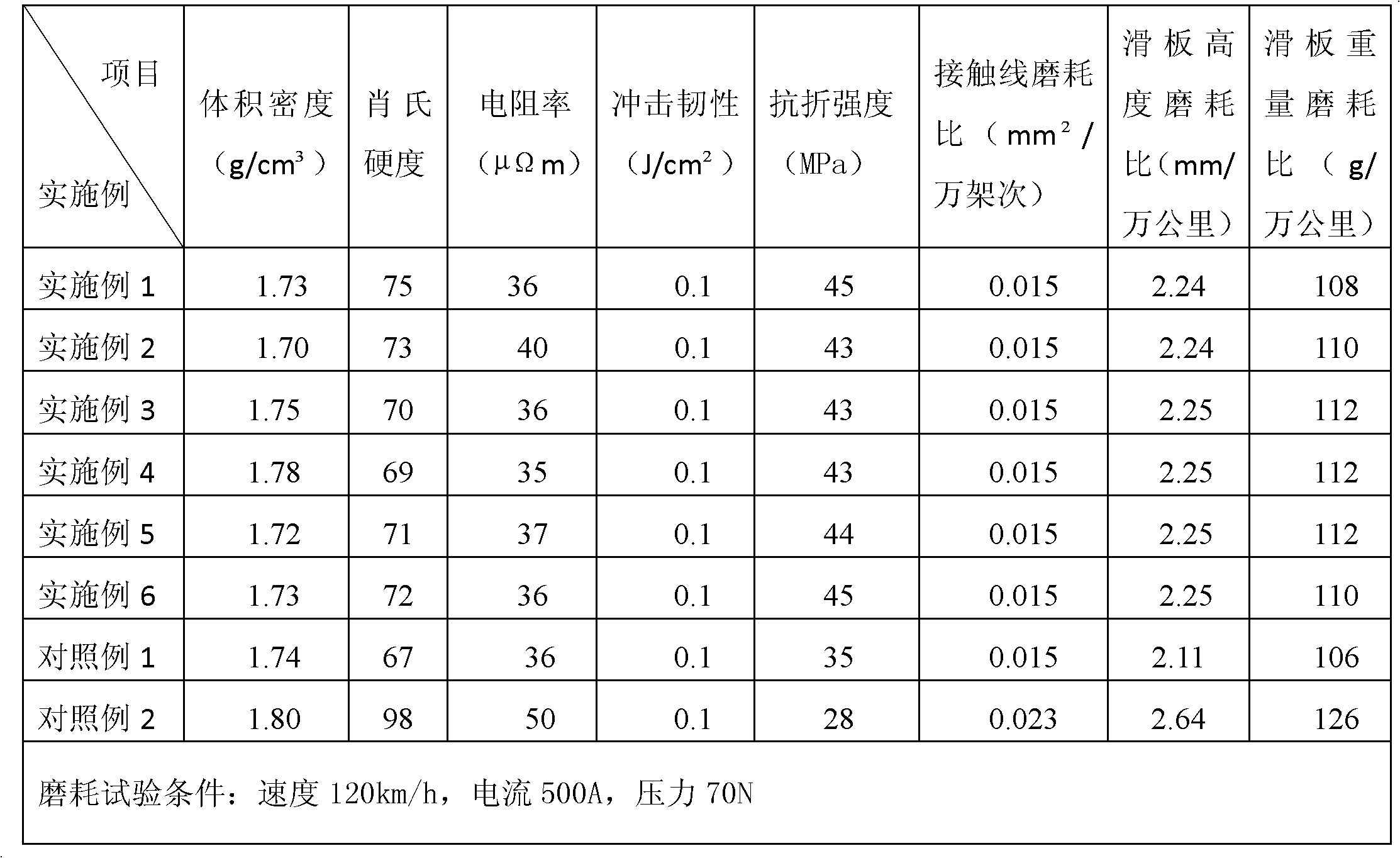

Examples

Embodiment 1

[0025] 1. Preparation of copper-graphite interlayer compound

[0026] 1) After mixing the natural flake graphite and anhydrous copper chloride evenly, add it into a stainless steel pressure tank, wherein the molar ratio of flake graphite and anhydrous copper chloride is 2:3;

[0027] 2) Seal the stainless steel pressure tank and put it into a well-type furnace, heat the well-type furnace to 450°C at a heating rate of 2°C / min, keep it warm for 72 hours, and then cool it down to room temperature naturally to prepare copper chloride-graphite interlayer compound;

[0028] 3) Spread the copper chloride-graphite interlayer compound on a stainless steel tray and put it into a hydrogen reduction furnace. Vacuumize the reduction furnace to 0.01MPa, then feed hydrogen at a flow rate of 1L / min, and at the same time flow at a rate of 1°C / min. The heating rate is to heat the reduction furnace to 480°C and keep it warm for 50 hours; then continue to heat the reduction furnace to 850°C at a...

Embodiment 2

[0035] 1. Preparation of copper-graphite interlayer compound

[0036] 1) After mixing the natural flake graphite and anhydrous copper chloride evenly, add it into a stainless steel pressure tank, wherein the molar ratio of flake graphite and anhydrous copper chloride is 1:2;

[0037] 2) Seal the stainless steel pressure tank and put it into a well-type furnace, heat the well-type furnace to 500°C at a heating rate of 5°C / min, keep it warm for 68 hours, and then cool it down to room temperature naturally to prepare copper chloride-graphite interlayer compound;

[0038] 3) Spread the copper chloride-graphite interlayer compound on a stainless steel tray and put it into a hydrogen reduction furnace. Vacuumize the reduction furnace to 0.01MPa, then feed hydrogen at a flow rate of 2L / min, and at the same time, use a flow rate of 2°C / min The heating rate is to heat the reduction furnace to 450°C and keep it warm for 45 hours; then continue to heat the reduction furnace to 900°C at ...

Embodiment 3

[0045] 1. Preparation of copper-graphite interlayer compound

[0046]1) After mixing the natural flake graphite and anhydrous copper chloride evenly, add it into a stainless steel pressure tank, wherein the molar ratio of flake graphite and anhydrous copper chloride is 3:4;

[0047] 2) Seal the stainless steel pressure tank and put it into a well-type furnace, heat the well-type furnace to 550°C at a heating rate of 3°C / min, keep it warm for 76 hours, and then cool it down to room temperature naturally to prepare copper chloride-graphite interlayer compound;

[0048] 3) Spread the copper chloride-graphite interlayer compound on a stainless steel tray and put it into a hydrogen reduction furnace. Vacuumize the reduction furnace to 0.01MPa, then feed hydrogen at a flow rate of 1L / min, and at the same time flow at a rate of 1°C / min. The heating rate is to heat the reduction furnace to 550°C and keep it warm for 52 hours; then continue to heat the reduction furnace to 870°C at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com