Plant cultivation method

A planting method and plant technology, applied in botany equipment and methods, plant protection covers, climate change adaptation, etc., can solve the problems of insufficient use of agricultural film, little blue light, and large investment, and achieve huge economic value and Practical significance, good spectral matching, and the effect of reducing pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of the aforementioned dual-functional light-changing agent is characterized in that, according to the design of the molecular formula, the rare earth ion and the inorganic salt solution are mixed in molar ratios, and a coprecipitation is formed under stirring conditions, and centrifugal separation, washing and drying, and drying in a reducing atmosphere Under high heat in microwave for 10~20 minutes or high temperature roasting at 800℃~1200℃ for 2~4 hours, the product can be obtained.

[0054] Preferably, the reducing atmosphere is carbon monoxide or a mixture of hydrogen and nitrogen.

[0055] Preferably, the precipitate and the flux are roasted under a reducing atmosphere; the flux is NaF, CaF 2 、BaF 2 , Li 2 CO 3 、K 2 CO 3 , CaCl 2 , KCl, NaCl, NH 4 Cl, H 3 BO 3 one or more of.

[0056] Preferably, the weight of the flux is 0.1-50% of the weight of the precipitate. More preferably, more preferably, the weight of the flux is 0.5-20% o...

Embodiment 1

[0058] (1) Synthesis of bifunctional light conversion agent Ca 0.7 Ba 0.3 f 2 :Eu

[0059] Weigh Ca(NO 3 ) 2 4H 2 O(14.8Kg), Ba(NO 3 ) 2 (5Kg), Eu 2 o 3 (17.00g), NH 4 F (11.5Kg), HNO 3 (25ml).

[0060] a. Use HNO first 3 Dissolved Eu 2 o 3 , adding Ca(NO 3 ) 2 4H 2 O and Ba(NO 3 ) 2 Prepare 0.25mol / L solution A;

[0061] Prepare 1mol / L NH 4 F solution B.

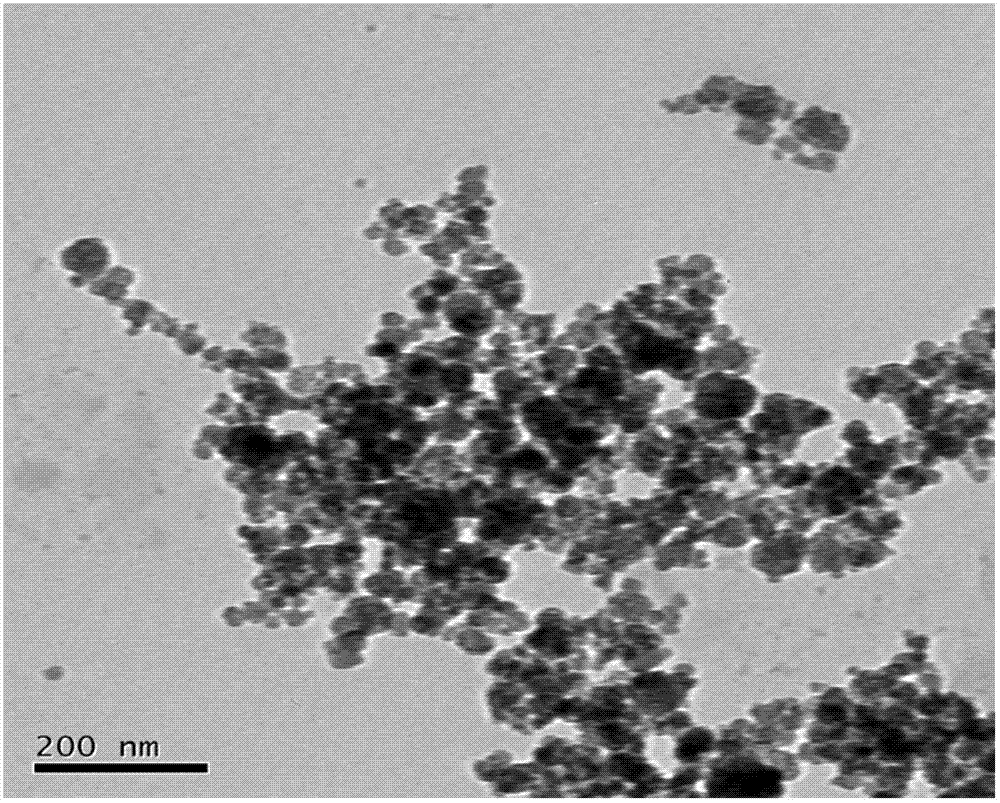

[0062] b. Under the condition of stirring, add solution A dropwise to solution B, continue stirring for 1 hour, centrifuge, and dry at 100°C. The SEM morphology of the precursor after drying is shown in the attached figure 1 As shown, its substance is a white lump.

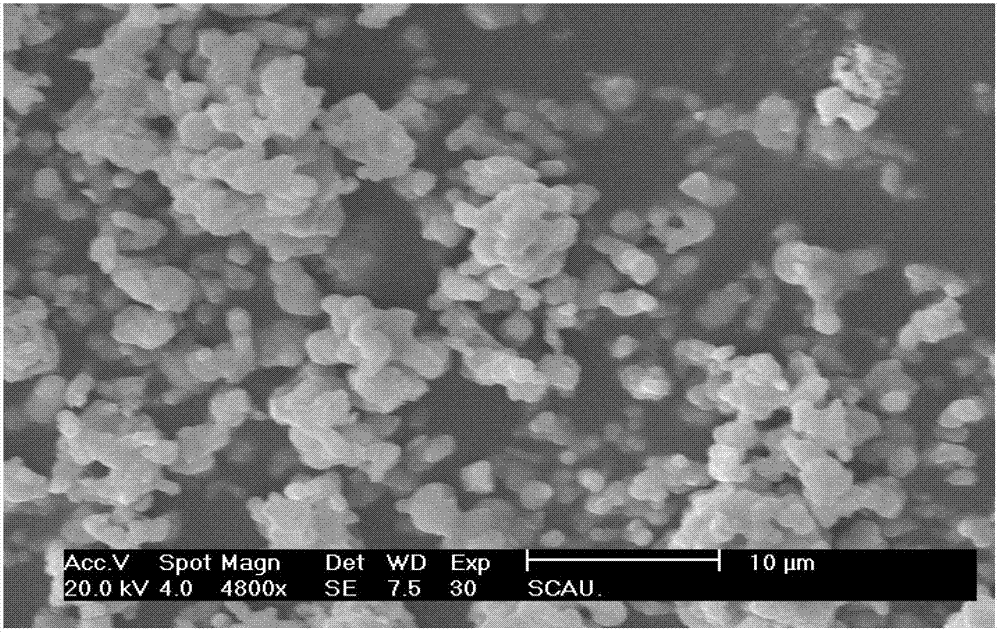

[0063] c. The above-mentioned precipitate after drying, after adding 0.5% of the flux CaF of the weight of the precipitate 2 Grinding, then calcination at 1200°C for 2 hours under a CO reducing atmosphere, and gradually cooling to obtain the sample. The SEM morphology characteristics of the sample are as attached figure 2 As shown, t...

Embodiment 2

[0069] (1) Synthesis of bifunctional light converting agent Ca 0.75 Zn 0.15 f 2 :Eu,Ce

[0070] Weigh Ca(NO 3 ) 2 4H 2O(17.6Kg), Zn(NO 3 ) 2 、Ce 2 o 3 And MgO (total 3.2Kg), Eu 2 o 3 (17.00g), NH 4 F (11.5Kg), HNO 3 (25ml).

[0071] a. Use HNO first 3 Dissolved Eu 2 o 3 、Ce 2 o 3 and MgO, adding Ca(NO 3 ) 2 4H 2 O and Zn(NO 3 ) 2 Prepare 0.25mol / L solution A;

[0072] Prepare 1mol / L NH 4 F solution B.

[0073] b. Under the condition of stirring, add solution A dropwise to solution B, continue stirring for 1 hour, centrifuge, and dry at 100°C.

[0074] c. The above-mentioned precipitate after drying is added with 10% flux CaCl of the weight of the precipitate 2 Grinding, then calcination at 800° C. for 4 hours under a reducing atmosphere of nitrogen-hydrogen mixed gas, and gradually cooling to obtain a sample.

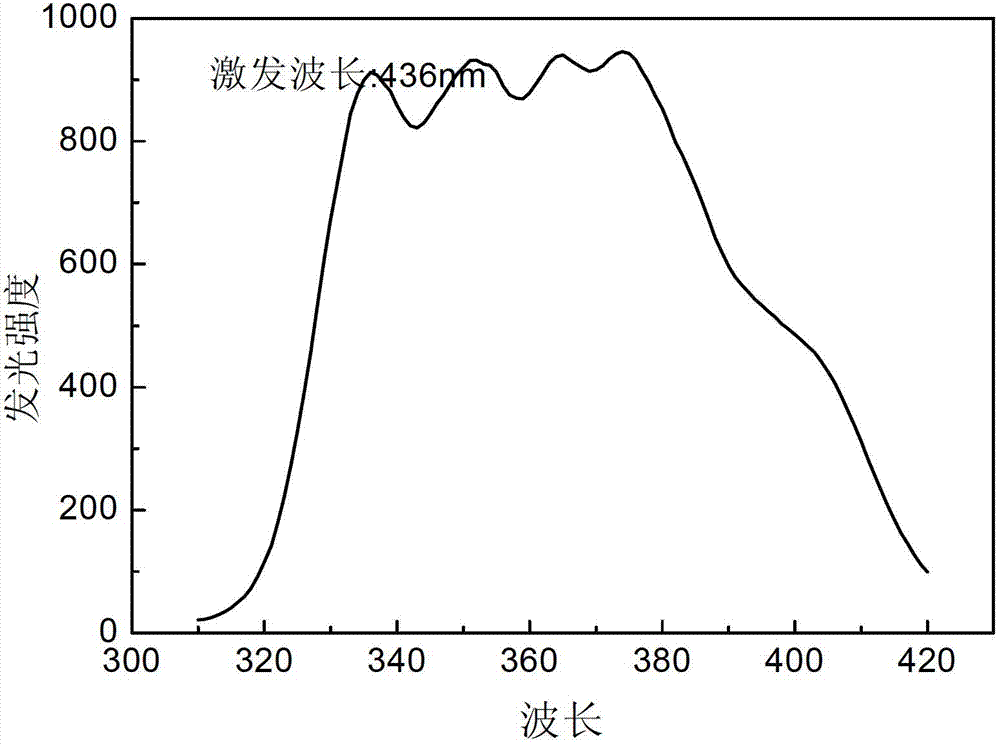

[0075] The excitation spectrum of the product in the ultraviolet region is attached image 3 As shown, the excitation spectrum in the green...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com