Silicon-based composite material, lithium ion battery, and preparation method and application thereof

A technology of silicon-based composite materials and intermediate materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as high production costs and unsatisfactory cycle performance, and achieve low cost and low pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

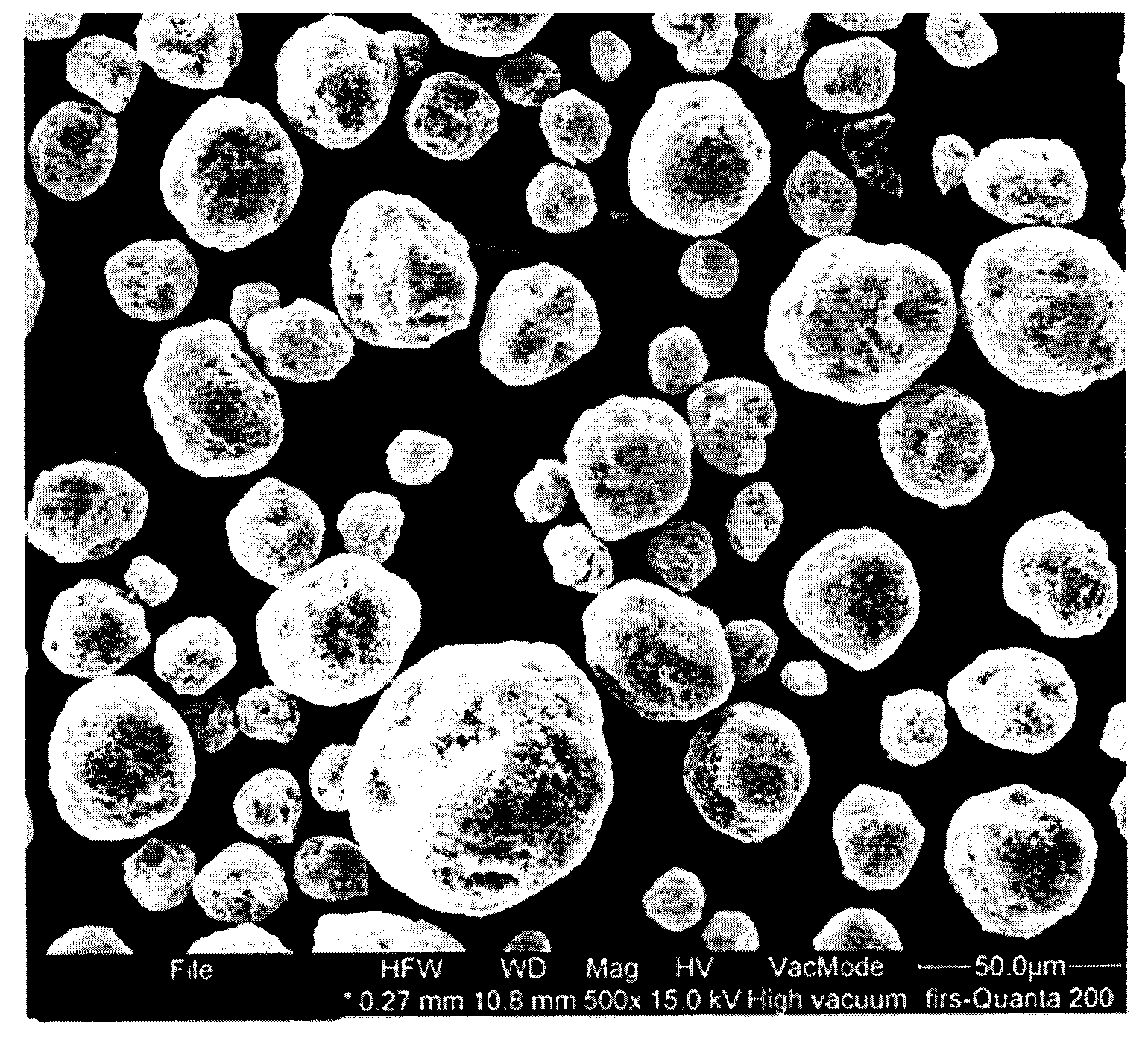

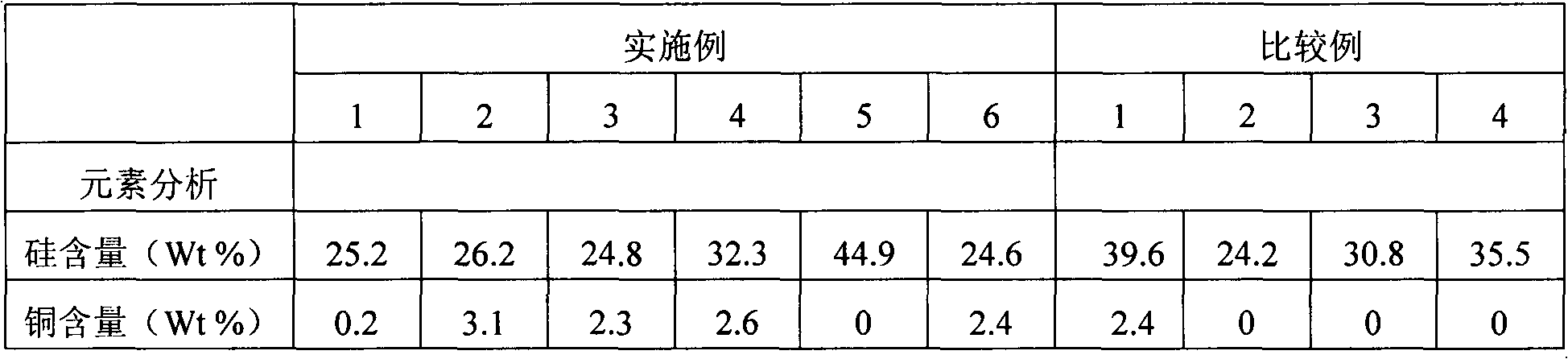

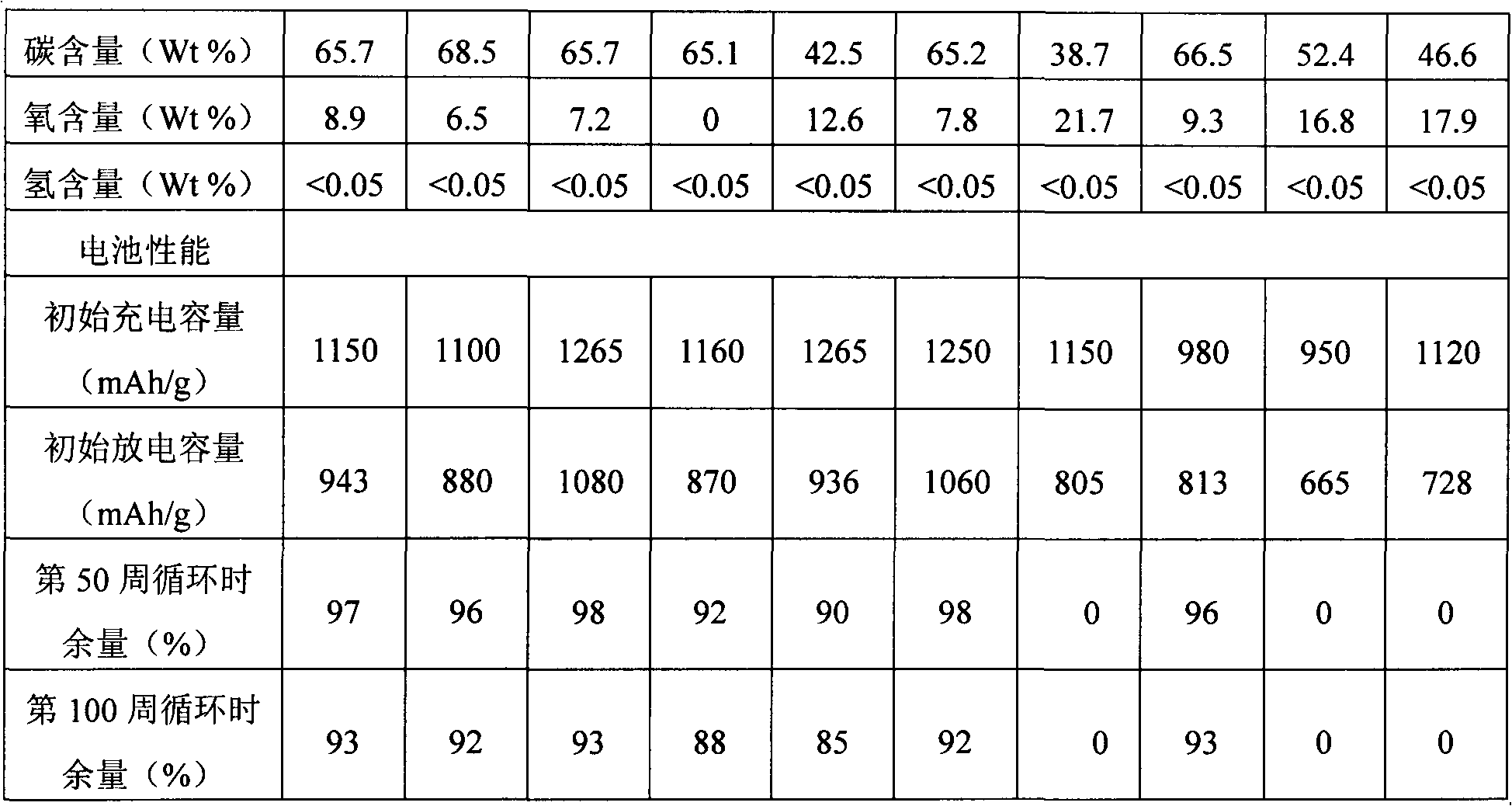

[0053] Get 2000g average molecular weight and be the polymethyl hydrogen siloxane of 800g / mol and 10g dicumyl peroxide (0.5wt%), add 10g (0.5wt%) particle diameter simultaneously and be the copper powder of 0.5 μ m, mix and put Stir in the reaction kettle, and pass through the nitrogen protection, gradually raise the temperature of the reaction kettle to 170 ° C, keep the reaction for 1 hour, cool to room temperature, and then discharge. Afterwards, the above-mentioned cross-linked cured product was calcined in a carbonization furnace at 600° C. for 6 hours. Get cooled discharge 1000g and 1000g particle diameter is 3 μm graphite and mix, add the aqueous solution 10kg that contains 2g (0.1wt%) CMC simultaneously and carry out wet ball milling. Spray drying is carried out when the particle size is 1 μm after ball milling. The air inlet temperature of the spray dryer is controlled at 200° C., the air outlet temperature is 100° C., and the spray frequency is 250 Hz. Spherical par...

Embodiment 2

[0055] Get 2000g of polymethylhydrogensiloxane with an average molecular weight of 5000g / mol and 100g of dicumyl peroxide (5wt%), add 100g (5wt%) of copper powder with a particle diameter of 1 μm at the same time, put into the reactor after mixing Stir in the middle, and pass through the nitrogen protection, gradually raise the temperature of the reactor to 350 ° C, keep the reaction for 8 hours, and discharge the material after cooling to room temperature. Afterwards, the above-mentioned crosslinked cured product was calcined in a carbonization furnace at 1000° C. for 6 hours. Get cooled discharge 1000g and 1000g particle diameter is 8 μ m graphite and mix, add the aqueous solution 10kg that contains 200g (10wt%) CMC simultaneously and carry out wet ball milling. Spray drying is carried out when the particle size is 10 μm after ball milling. The air inlet temperature of the spray dryer is controlled at 300° C., the air outlet temperature is 150° C., and the spray frequency is...

Embodiment 3

[0057] Get 2000g average molecular weight and be 2000g / mol polymethylhydrogen siloxane and 50g (2.5wt%) dicumyl peroxide, add 40g (2wt%) particle diameter simultaneously and be the copper powder of 0.5 μ m, put into after mixing Stir in the reaction kettle, and pass nitrogen protection, gradually raise the temperature of the reaction kettle to 250° C., keep the reaction for 4 hours, cool to room temperature, and then discharge. Afterwards, the above-mentioned cross-linked cured product was calcined in a carbonization furnace at 800° C. for 6 hours. 1000 g of discharged material after cooling is mixed with 1000 g of graphite with a particle size of 5 μm, and 10 kg of an aqueous solution containing 100 g (5 wt %) of CMC is added simultaneously for wet ball milling. Spray drying is carried out when the particle size is 4 μm after ball milling. The air inlet temperature of the spray dryer is controlled at 250° C., the air outlet temperature is 125° C., and the spray frequency is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com