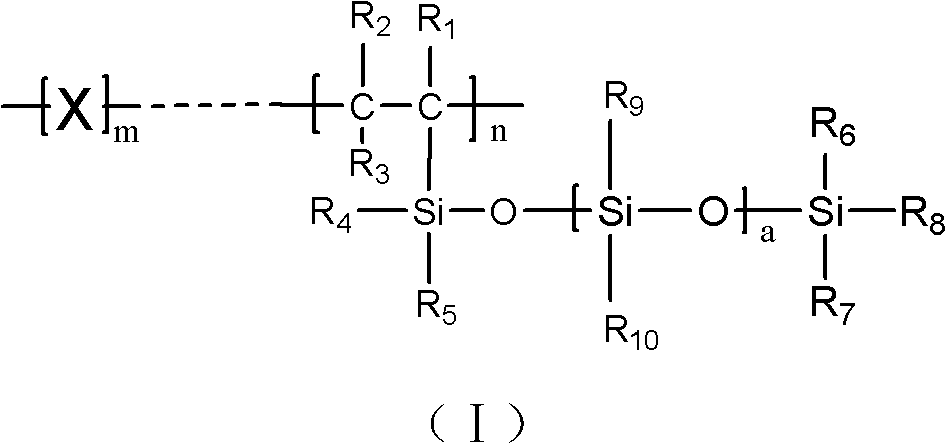

Application of organic silicone modified high-molecular compound as seed coating film former

A technology of high molecular compound and organic silicon, which is applied in the direction of seed coating/seed dressing, etc., can solve the problems of unreported use and achieve the goal of improving coating uniformity, excellent weather resistance, good water resistance and water permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

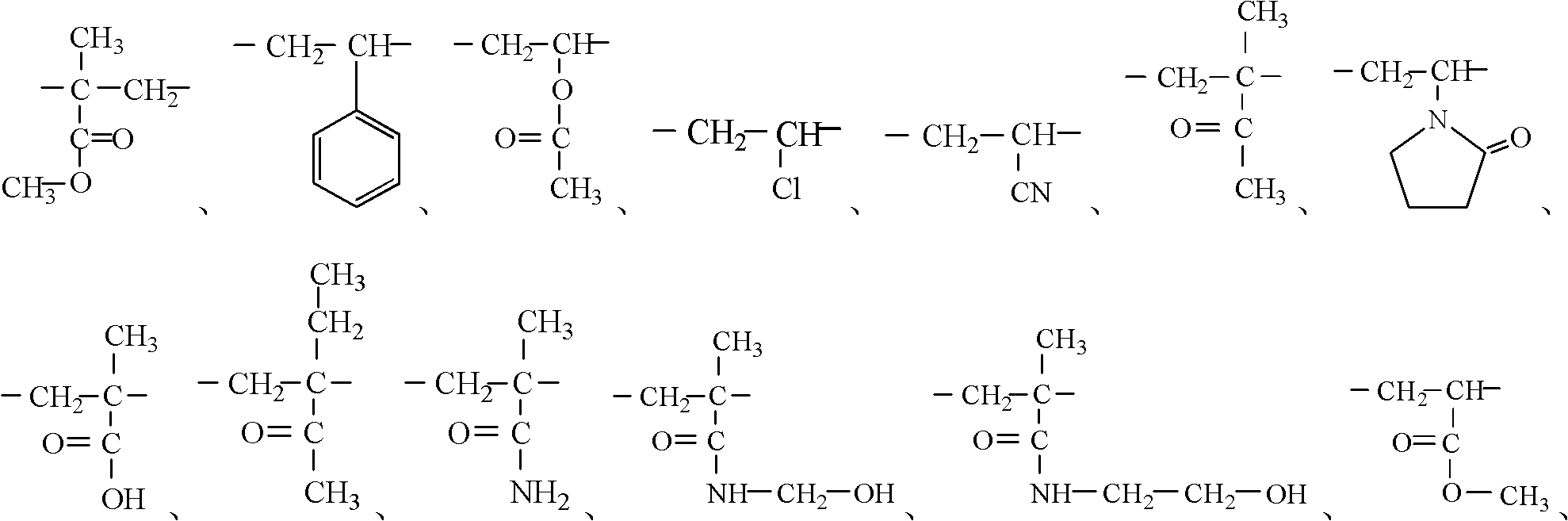

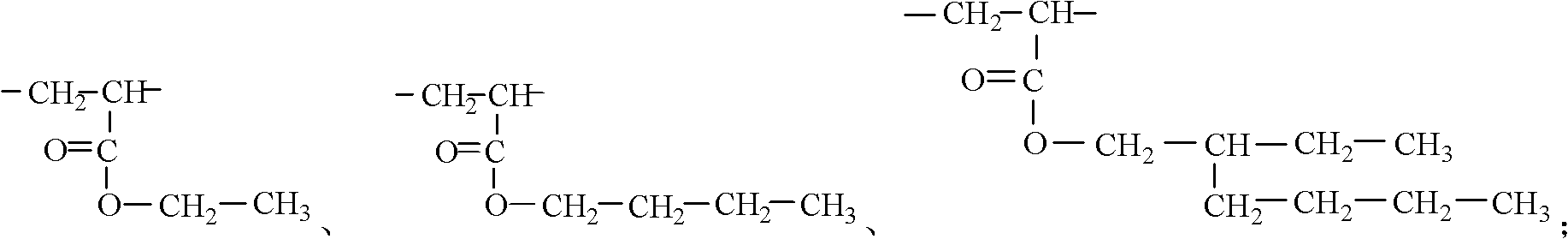

Embodiment 1

[0071] In a stirring four-neck flask, add 0.5 parts of vinyltrimethoxysilane, 5 parts of octamethylcyclotetrasiloxane, 1.5 parts of 99% acrylamide, 1 part of acrylic acid, 0.1 parts of ammonium persulfate, 5 parts of butyl acrylate, 1 part of acrylonitrile, 0.2 part of sodium dodecylbenzenesulfonate, 0.1 part of N, N, N', N'-tetramethylethylenediamine, 750 parts of deionized water, After raw materials, stir rapidly for 30 minutes, then heat to 75°C--80°C, keep warm for 2 hours, add polyvinyl alcohol solution containing 22.1 parts of polyvinyl alcohol and 100 parts of deionized water to the reaction system, control the temperature at 80°C--82°C, continue stirring and reacting for 1 hour after adding, stop heating, cool to room temperature, adjust pH value with ammonia water, stir evenly and discharge. A viscous transparent liquid was obtained with a pH value of 6.8, a viscosity of 2200 mPaS at room temperature, a viscosity-average molecular weight of 800,000, m≈2000, n≈1060.

Embodiment 2

[0073]In a stirring four-neck flask, add 0.5 parts of vinyltrimethoxysilane, 5 parts of octamethylcyclotetrasiloxane, 1.3 parts of 99% acrylamide, 1 part of acrylic acid, 0.2 parts of ammonium persulfate, 5 parts of butyl acrylate, 1 part of methyl methacrylate, 0.1 part of sodium dodecylbenzenesulfonate, 0.1 part of N, N, N', N'-tetramethylethylenediamine, 125 parts of deionized water, After adding all the raw materials, stir rapidly for 30 minutes, then heat to 75°C--80°C, keep warm for 2 hours, add polyvinyl acetate containing 22.3 parts of polyvinyl acetate and 100 parts of deionized water to the reaction system The temperature of the solution is controlled at 80°C--82°C. After the addition, continue to stir and react for 1 hour, stop heating, cool to room temperature, adjust the pH value with ammonia water, stir evenly and discharge. A viscous transparent liquid was obtained with a pH value of 6.8, a viscosity of 1900 mPaS at room temperature, a viscosity-average molecula...

Embodiment 3

[0075] In a four-necked flask with stirring, add 0.5 parts of vinyltriethoxysilane, 5 parts of tetramethyltetravinylcyclotetrasiloxane, and then add 1 part of 99% acrylamide, 1 part of acrylic acid, persulfuric acid 0.1 part of ammonium, 5 parts of N-vinylpyrrolidone, 1 part of acrylonitrile, 0.2 part of sodium dodecylbenzenesulfonate, 0.1 g of N, N, N', N'-tetramethylethylenediamine, deionized water 75 parts, after adding all the raw materials, stir rapidly for 30 minutes, then heat to 75°C--80°C, keep warm for 2 hours, add 22.6 parts of carboxymethyl cellulose and 150 parts of deionized water to the reaction system For carboxymethyl cellulose solution, control the temperature at 85°C--87°C. After the addition and continue to stir for 3 hours, stop heating, cool to room temperature, adjust the pH value with ammonia water, stir evenly and discharge. A viscous transparent liquid was obtained with a pH value of 6.8, a viscosity of 2400 mPaS at room temperature, a viscosity-avera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com