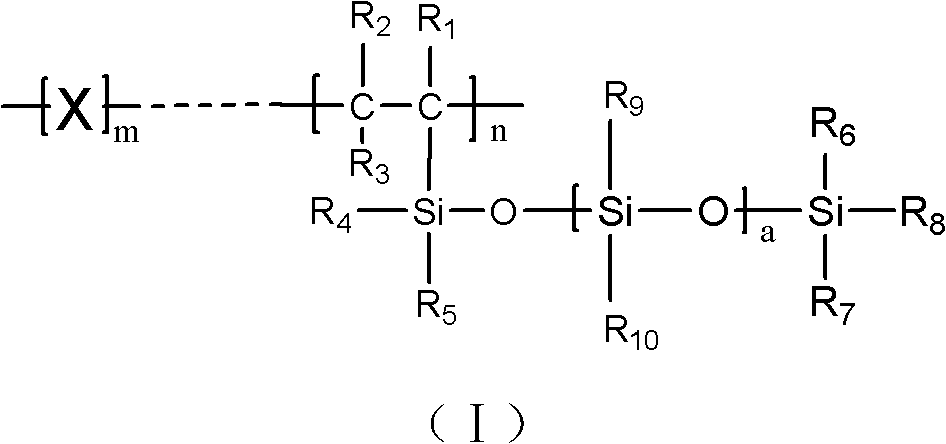

Application of organic silicone modified high-molecular compound as seed coating film former

A technology of high molecular compound and organic silicon, which is applied in the direction of seed coating/seed dressing, etc., can solve the problems of unreported use, etc., and achieve the improvement of coating uniformity, brightness and color brilliance, and good water resistance The effect of sex and water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

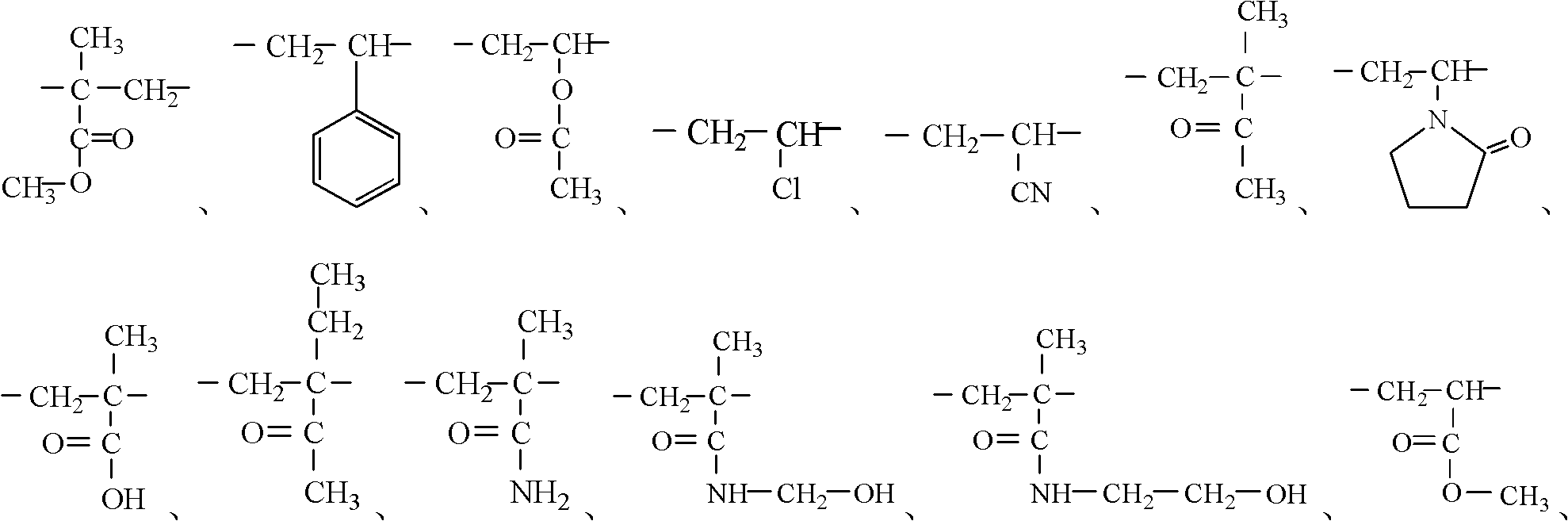

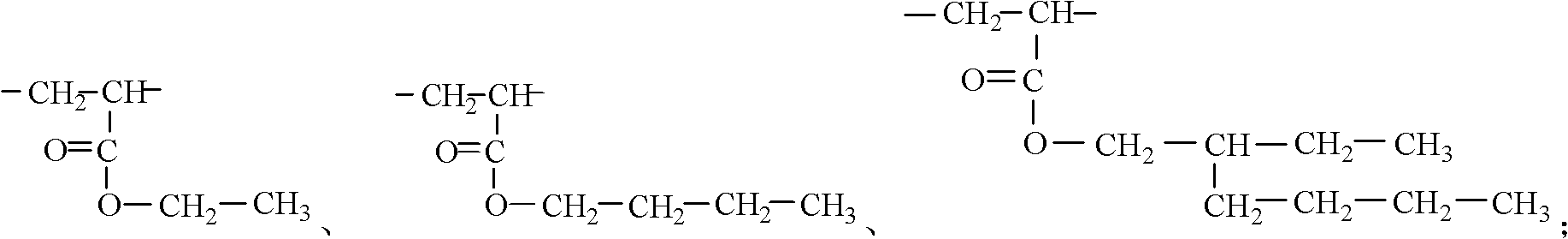

Method used

Image

Examples

Embodiment 1

[0071] In a four-necked flask with stirring, add 0.5 parts of vinyltrimethoxysilane, 5 parts of octamethylcyclotetrasiloxane, 1.5 parts of 99% acrylamide, 1 part of acrylic acid, 0.1 part of ammonium persulfate, 5 parts of butyl acrylate, 1 part of acrylonitrile, 0.2 part of sodium dodecylbenzene sulfonate, 0.1 part of N,N,N',N'-tetramethylethylenediamine, 750 parts of deionized water, add each After raw materials, quickly stir for 30 minutes, and then heat to 75 ℃-80 ℃, heat preservation and reaction for 2 hours, add polyvinyl alcohol solution containing 22.1 parts of polyvinyl alcohol and 100 parts of deionized water to the reaction system, and control the temperature at 80°C-82°C, after adding and continuing to stir and react for 1 hour, stop heating, cool to room temperature, adjust pH value with ammonia water, and stir to evenly discharge. The viscous transparent liquid is obtained, the pH is 6.8, the viscosity is 2200 mPaS at room temperature, the viscosity average molecu...

Embodiment 2

[0073] In a four-necked flask with stirring, add 0.5 parts of vinyltrimethoxysilane, 5 parts of octamethylcyclotetrasiloxane, 1.3 parts of 99% acrylamide, 1 part of acrylic acid, 0.2 parts of ammonium persulfate, 5 parts of butyl acrylate, 1 part of methyl methacrylate, 0.1 part of sodium dodecylbenzene sulfonate, 0.1 part of N,N,N',N'-tetramethylethylenediamine, 125 parts of deionized water, After adding all the raw materials, stir quickly for 30 minutes, then heat to 75°C-80°C, keep warm and react for 2 hours, add polyvinyl acetate containing 22.3 parts of polyvinyl acetate and 100 parts of deionized water to the reaction system Control the temperature of the solution at 80°C-82°C. After adding the solution, continue to stir and react for 1 hour, stop heating, cool to room temperature, adjust the pH value with ammonia water, and stir evenly to discharge. The viscous transparent liquid is obtained, the pH is 6.8, the viscosity is 1900 mPaS at room temperature, the viscosity av...

Embodiment 3

[0075] In a four-necked flask with stirring, add 0.5 parts of vinyl triethoxy silane, 5 parts of tetramethyl tetravinyl cyclotetrasiloxane, and then add 1 part of 99% acrylamide, 1 part of acrylic acid, and persulfuric acid. 0.1 part of ammonium, 5 parts of N-vinylpyrrolidone, 1 part of acrylonitrile, 0.2 part of sodium dodecylbenzene sulfonate, 0.1g of N,N,N',N'-tetramethylethylenediamine, deionized water 75 parts, after adding each raw material, quickly stir for 30 minutes, then heat to 75 ℃-80 ℃, keep the temperature for 2 hours, add 22.6 parts of carboxymethyl cellulose and 150 parts of deionized water to the reaction system Control the temperature of the carboxymethyl cellulose solution at 85°C-87°C. After the addition, continue to stir and react for 3 hours, stop heating, cool to room temperature, adjust the pH value with ammonia water, and stir to uniformly discharge. The viscous transparent liquid is obtained, the pH is 6.8, the viscosity is 2400 mPaS at room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| suspension rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com