Preparation process of infant formula milk powder

A technology of infant formula and preparation technology, which is applied in the field of food processing, and can solve problems such as burnt smell, dull color, bad flavor and tissue state of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention discloses a preparation process of formula milk powder for infants and young children. Those skilled in the art can learn from the content of this article and appropriately improve the process parameters to realize it. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method and application of the present invention have been described through preferred embodiments, and the relevant personnel can obviously make changes or appropriate changes and combinations to the method and application described herein without departing from the content, spirit and scope of the present invention to realize and Apply the technology of the present invention.

[0029] The invention provides a preparation process of formula milk powder for infants and young children. The raw materials include raw milk and acceptable ingredient...

Embodiment 1

[0041] The preparation of embodiment 1 infant formula milk powder

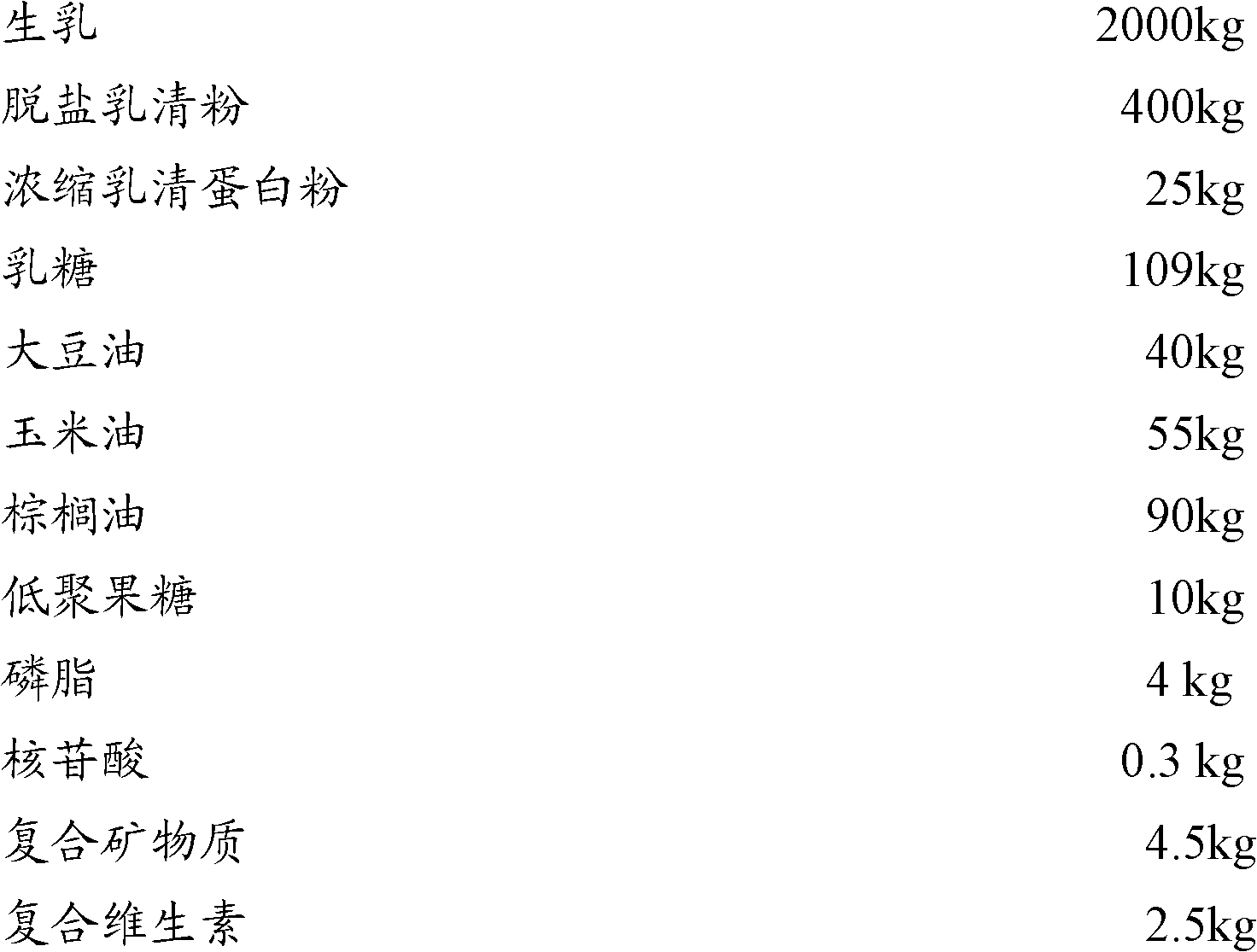

[0042] formula:

[0043]

[0044] in:

[0045] Multi-vitamins including vitamin A, vitamin D, vitamin E, vitamin K 1 , Vitamin B 1 , Vitamin B 2 , Vitamin B 6 , Vitamin B 12 , vitamin C, folic acid, biotin, niacinamide, calcium pantothenate, taurine;

[0046] Complex minerals include ferrous lactate, zinc lactate, copper sulfate, potassium iodate, calcium carbonate, manganese sulfate, sodium nitrite;

[0047] Nucleotides include inosinic acid, adenine nucleotide, guanine nucleotide, cytosine nucleotide, uracil nucleotide;

[0048] Preparation Process:

[0049] Collect 2000kg of raw milk. After acceptance, preheat the milk to 55°C, and divide the raw milk into separated milk and bacteria-containing milk through a centrifugal sterilizer. The bacteria-containing milk is sterilized at 127°C for 3 seconds, then mixed into the separated milk, and cooled for storage. Finally, mix desalted whey powder, con...

Embodiment 2

[0050] The preparation of embodiment 2 infant formula milk powder

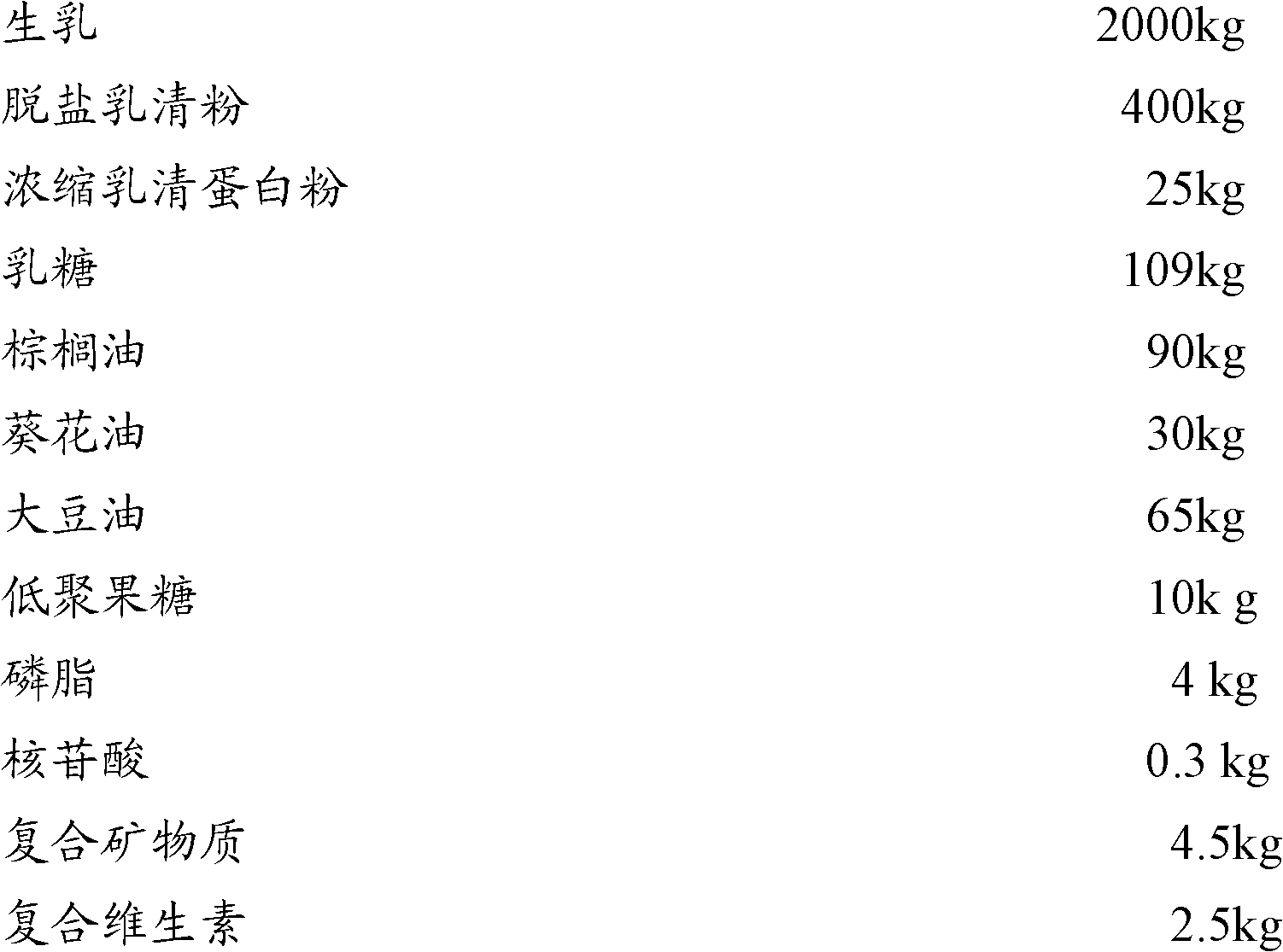

[0051] formula:

[0052]

[0053] in:

[0054] Multi-vitamins including vitamin A, vitamin D, vitamin E, vitamin K 1 , Vitamin B 1 , Vitamin B 2 , Vitamin B 6 , Vitamin B 12 , vitamin C, folic acid, biotin, niacinamide, calcium pantothenate, taurine;

[0055] Complex minerals include ferrous lactate, zinc lactate, copper sulfate, potassium iodate, calcium carbonate, manganese sulfate, sodium selenite;

[0056] Nucleotides include inosinic acid, adenine nucleotide, guanine nucleotide, cytosine nucleotide, and uracil nucleotide.

[0057] Preparation Process:

[0058] Collect 2000Kg of raw milk. After acceptance, preheat the milk to 63°C, and divide the raw milk into separated milk and bacteria-containing milk through a centrifugal sterilizer. The bacteria-containing milk is sterilized at 135°C for 5 seconds, then mixed into the separated milk, and cooled for storage. Finally, mix desalted whey powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com