Preparation method of organic-inorganic hybridized monolithic column

A monolithic column and inorganic technology, applied in the field of organic-inorganic hybrid monolithic column and its preparation, to achieve the effect of uniform mesopore diameter, easy column filling operation, and compact monolithic column structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of organic-inorganic hybrid monolithic column

[0026] Firstly, the inner wall of the capillary with 75 μm and 100 μm inner diameter is pretreated. Rinse the capillary with 0.1mol / L hydrochloric acid for 4 hours, rinse with water until neutral, then rinse with 1mol / L NaOH for 2 hours, then rinse with water and methanol for 0.5 hours respectively, and then keep it at 120°C for 3 hours under nitrogen, until it drops to After room temperature, seal both ends of the capillary for use.

[0027] Add 30 mg of Pluronic F127, 350 μL of methanol, 20 μL of water, and 20 μL of hydrochloric acid (0.5 mol / L) into a 1.5 mL centrifuge tube, and ultrasonically dissolve it completely. Add another 180 µL tetraethoxysilane, 100 µL octyltriethoxysilane, and vortex for 3 min. Put into 60 ℃ water bath and hydrolyze for 4 hours. After hydrolysis, put into ice water and cool to 0°C, add 6 mg of dodecylamine, vortex for 1 minute, draw the solution with a syringe, filter...

Embodiment 2

[0033] Example 2: Adjusting the overall column morphology and column efficiency by adjusting the amount of porogen

[0034] The synthesis method of the monolithic column is the same as in Example 1, and the composition of the specific synthesis raw materials is shown in Table 1. The column A is an octyl hybrid monolithic column made of a traditional one-component porogen. Columns B-D are monolithic columns made of binary porogens with different ratios of porogens.

[0035] Table 1: Raw material ratio of four kinds of monolithic columns in embodiment two

[0036]

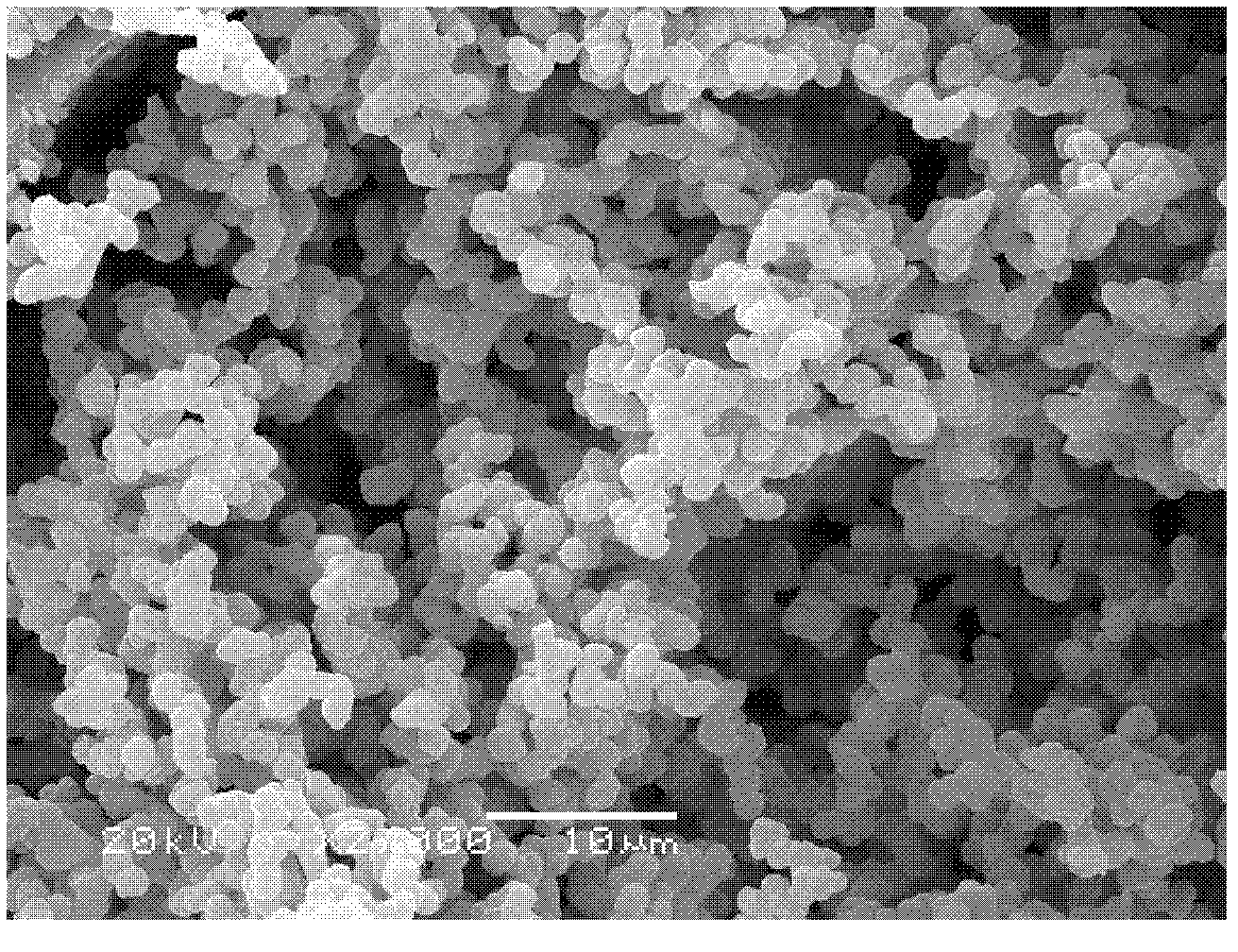

[0037] Figure 4The scanning electron micrographs of columns A-D show that after the addition of Pluronic F127, the morphology of the overall column changes from aggregated spherical to typical bicontinuous structure. And with the increase of the amount of Pluronic F127 added, the material through-hole size becomes smaller. Because the formation of monolithic materials is the result of the combined action of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Column length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com