Preparation method for gold-tin eutectic solder

A tin alloy and solder technology, applied in the field of multilayer metal alloy film preparation, can solve the problems of poor control of electroplating reaction, difficulty in precise control of thickness and composition, low utilization rate of electron beam evaporation materials, etc., to achieve fast deposition rate, Guaranteed consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings.

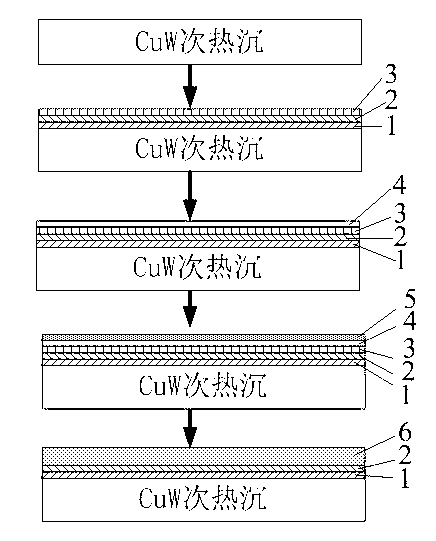

[0024] Such as figure 1 Shown is the production flow chart of the present invention. The figure is a schematic cross-sectional view of material processing, in which the CuW secondary heat sink is used as the underlying material.

[0025] Put the prepared CuW secondary heat sink into the magnetron sputtering coating machine, deposit by magnetron sputtering coating technology, and deposit the metal film on the CuW secondary heat sink successively; deposit a layer of Ti or Ni film 1 at the bottom, Deposit a layer of Pt film 2 on the Ti or Ni film 1 again, and finally deposit a layer of Au film 3 on the Pt film 2, so as to form an underlying metal film such as Ti / Pt / Au or Ni / Pt / Au. CuW secondary heat sink, the total thickness of the deposited Ti / Pt / Au or Ni / Pt / Au bottom metal film is controlled between 850~900nm.

[0026] Put the above-mentioned CuW secondary heat sink with Ti / Pt / Au or Ni / P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com