Method for preparing nano-material lead selenide through organic phase method

A technology of nanomaterials and lead selenide, applied in the direction of nanotechnology, nanotechnology, binary selenium/tellurium compounds, etc., can solve the problems of cumbersome operation, long duration and high cost, and achieve simple preparation process and strong practicability , the effect of little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The specific preparation steps of this embodiment are as follows:

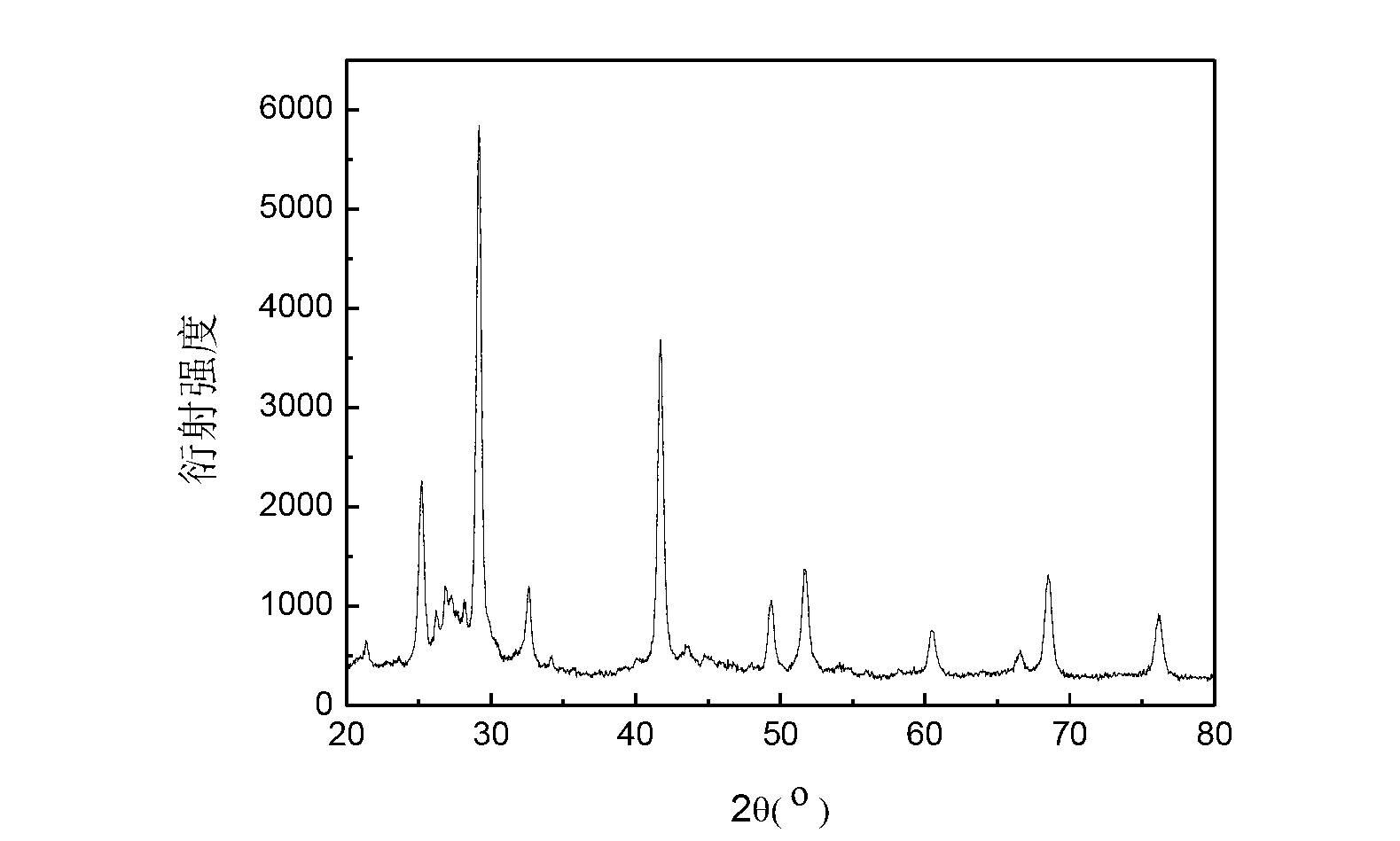

[0023] First weigh 0.005mol of selenium powder in a three-necked bottle, add 0.01mol of sodium borohydride and 30ml of anhydrous tetrahydrofuran, and react in an ice bath under the protection of argon until light yellow to generate the required sodium selenium hydride solution; then weigh 0.005 Put 80ml of anhydrous tetrahydrofuran into the three-necked bottle, pass argon to the solution system to remove dissolved oxygen, stir rapidly under the protection of argon, add the newly prepared sodium selenium hydride solution, heat to 60°C, and reflux for 0.5h After the reaction was stopped, after the solution was naturally cooled to room temperature, it was washed with absolute ethanol, centrifuged, and vacuum-dried to obtain a black powdery PbSe nanocrystalline material, which was spherical in shape and had an average diameter of 10.58nm.

Embodiment 2

[0025] The specific preparation steps of this embodiment are as follows:

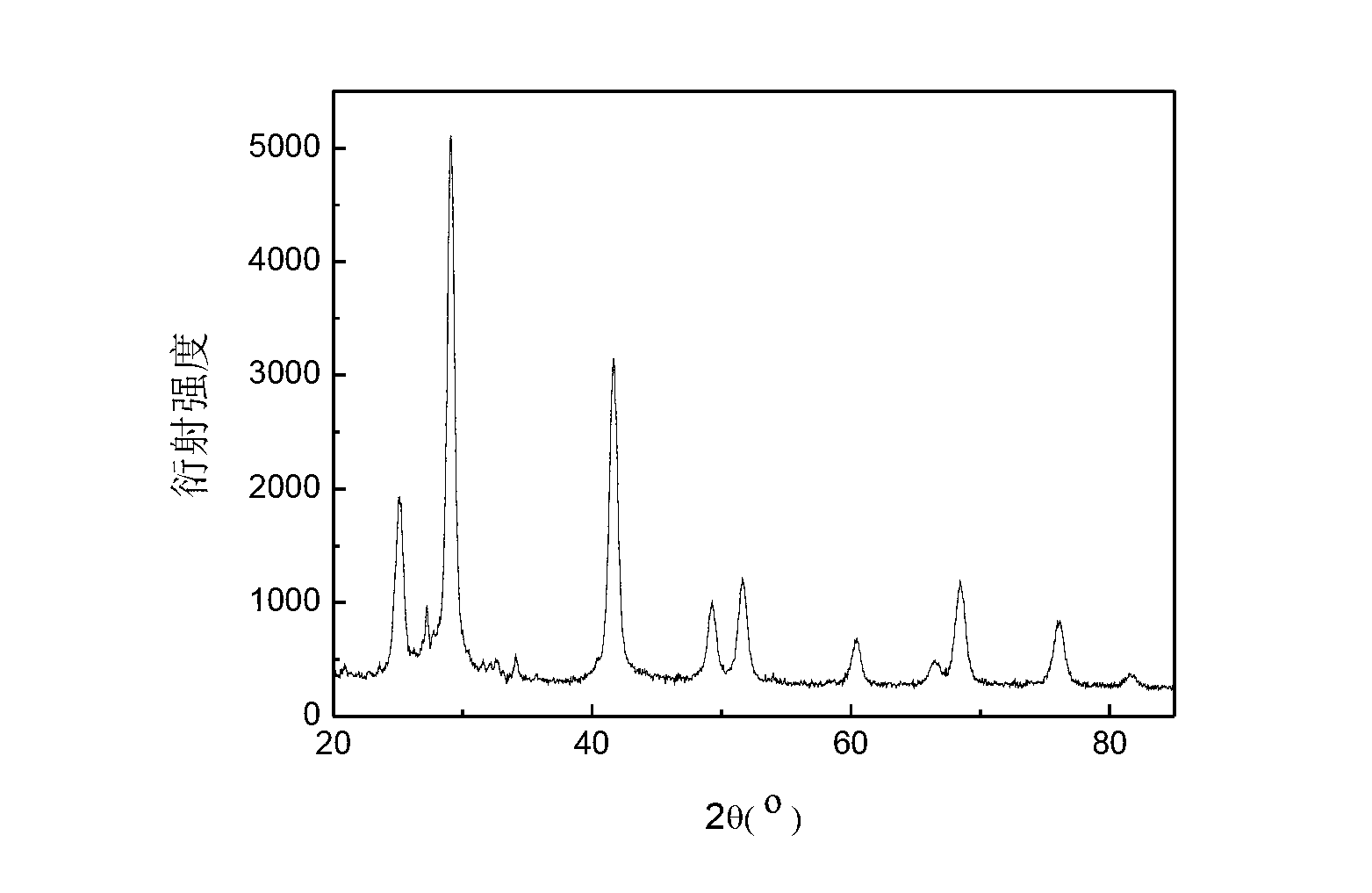

[0026] First weigh 0.005mol of selenium powder in a three-necked bottle, add 0.01mol of sodium borohydride and 30ml of anhydrous tetrahydrofuran, and react in an ice bath under the protection of argon until light yellow to generate the required sodium selenium hydride solution; then weigh 0.005 mol of lead acetate in a three-necked flask, add 80ml of anhydrous tetrahydrofuran. Pass argon to the solution system to remove dissolved oxygen, add the newly prepared sodium selenium hydride solution with rapid stirring under the protection of argon, heat to 70 ° C, and stop the reaction after reflux for 0.5 h. After the solution is naturally cooled to room temperature, use After washing with water and ethanol, centrifuging and vacuum drying, a black powdery PbSe nanocrystalline material was obtained, the shape of which was spherical nanoparticles, and the average diameter was 8.84nm.

Embodiment 3

[0028] The specific preparation steps of this embodiment are as follows:

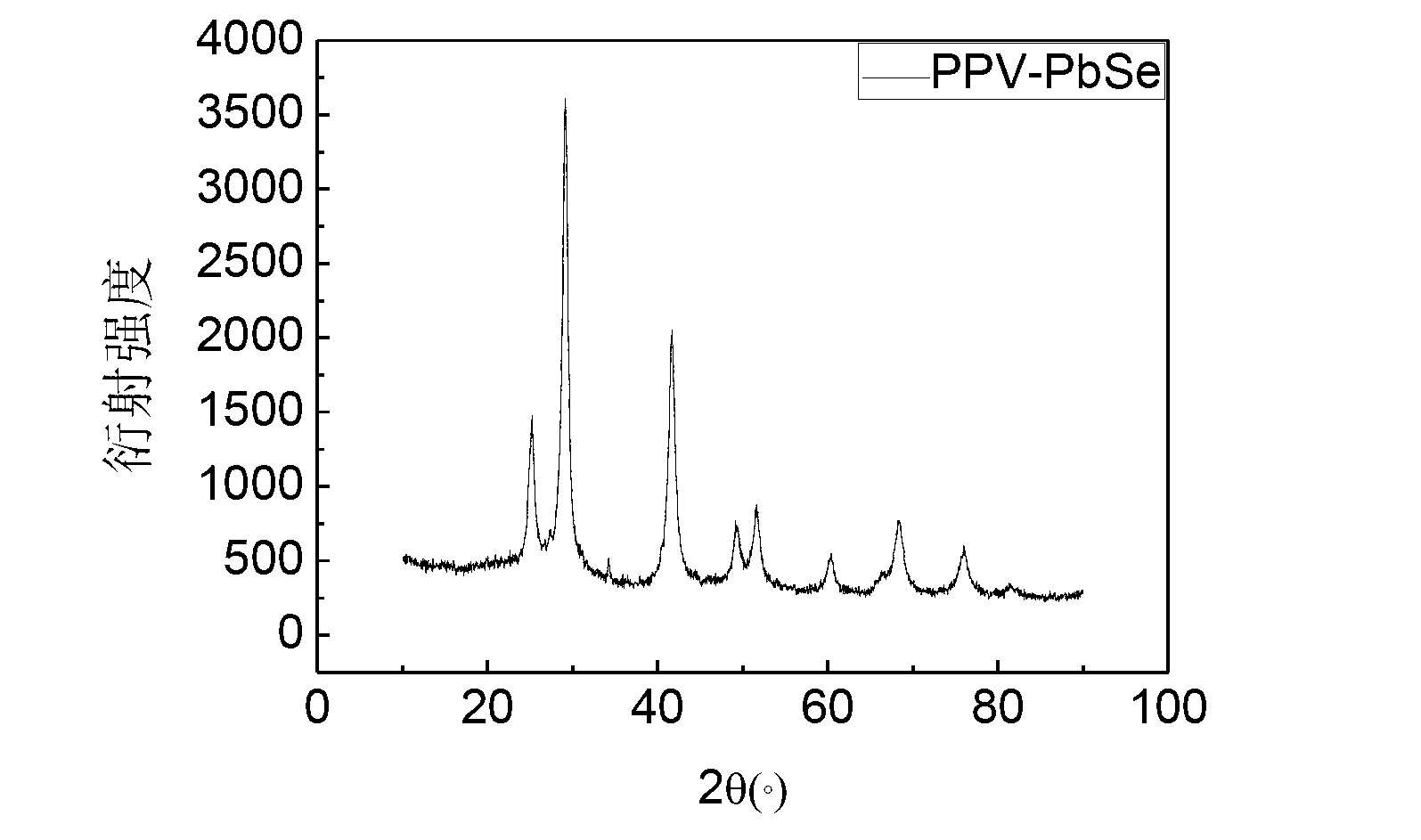

[0029] First weigh 0.005mol of selenium powder in a three-necked bottle, add 0.01mol of sodium borohydride and 30ml of anhydrous tetrahydrofuran, and react in an ice bath under the protection of argon until light yellow to generate the required sodium selenium hydride solution; then weigh 0.005 mol of lead acetate in a three-necked flask, add 80ml of anhydrous tetrahydrofuran. Pass argon to the solution system to remove dissolved oxygen, quickly stir and add the newly prepared sodium selenium hydride solution under the protection of argon, heat to 60 ° C, and stop the reaction after reflux for 1.0 h. After the solution is naturally cooled to room temperature, use After washing with water and ethanol, centrifuging and vacuum drying, a black powdery PbSe nanocrystalline material was obtained, the shape of which was spherical nanoparticles, and the average diameter was 4.36nm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap