Sequencing batch completely autotrophic ammonia removal technology running method

A technology of full autotrophic denitrification and operation method, applied in the field of sequencing batch full autotrophic denitrification CANON process, which can solve the problems of long startup time and harsh operating conditions of the autotrophic denitrification CANON process, and save the startup time. , ending a simple, effective, easy-to-control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

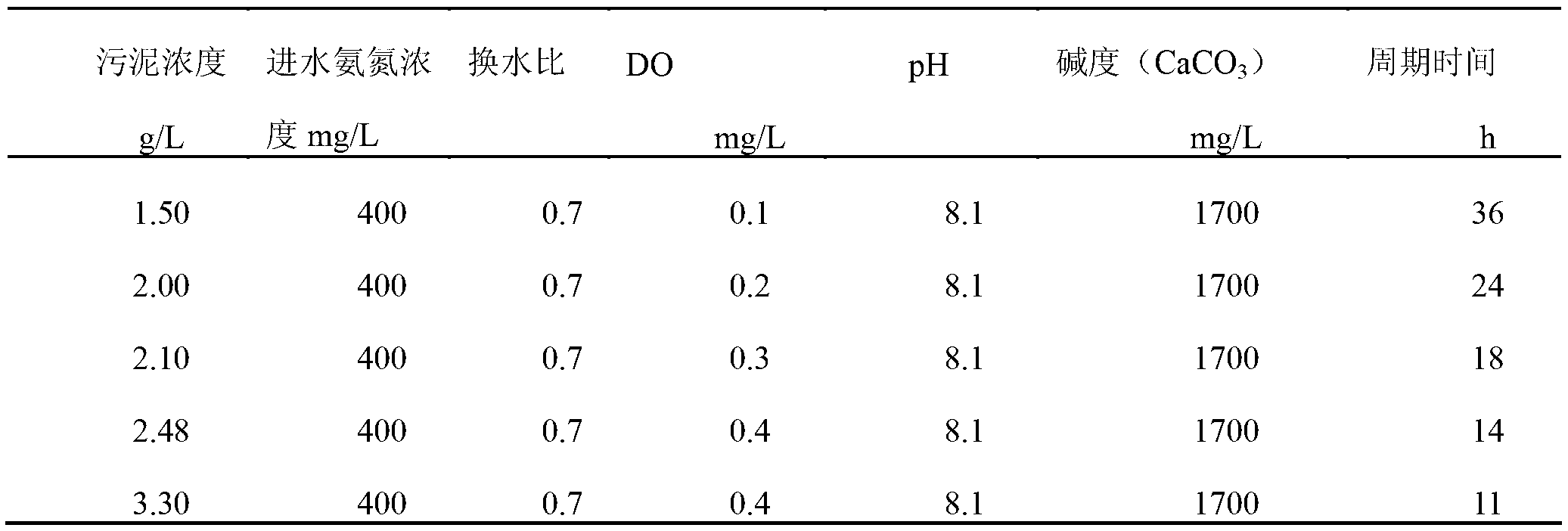

[0031] Sequence batch CANON process to treat artificial high ammonia nitrogen distribution water, add appropriate amount (NH 4 ) 2 SO 4 , NaHCO 3 、KH 2 PO 4 formulated without organic carbon sources. The specific water quality is as follows:

[0032] The mass concentration of ammonia nitrogen is 380-420mg / L; the mass concentration of nitrite nitrogen is 0-5mg / L; the mass concentration of phosphate is 0.5-2mg / L; the mass concentration of alkalinity (as CaCO 3 ) is 1600-1800mg / L.

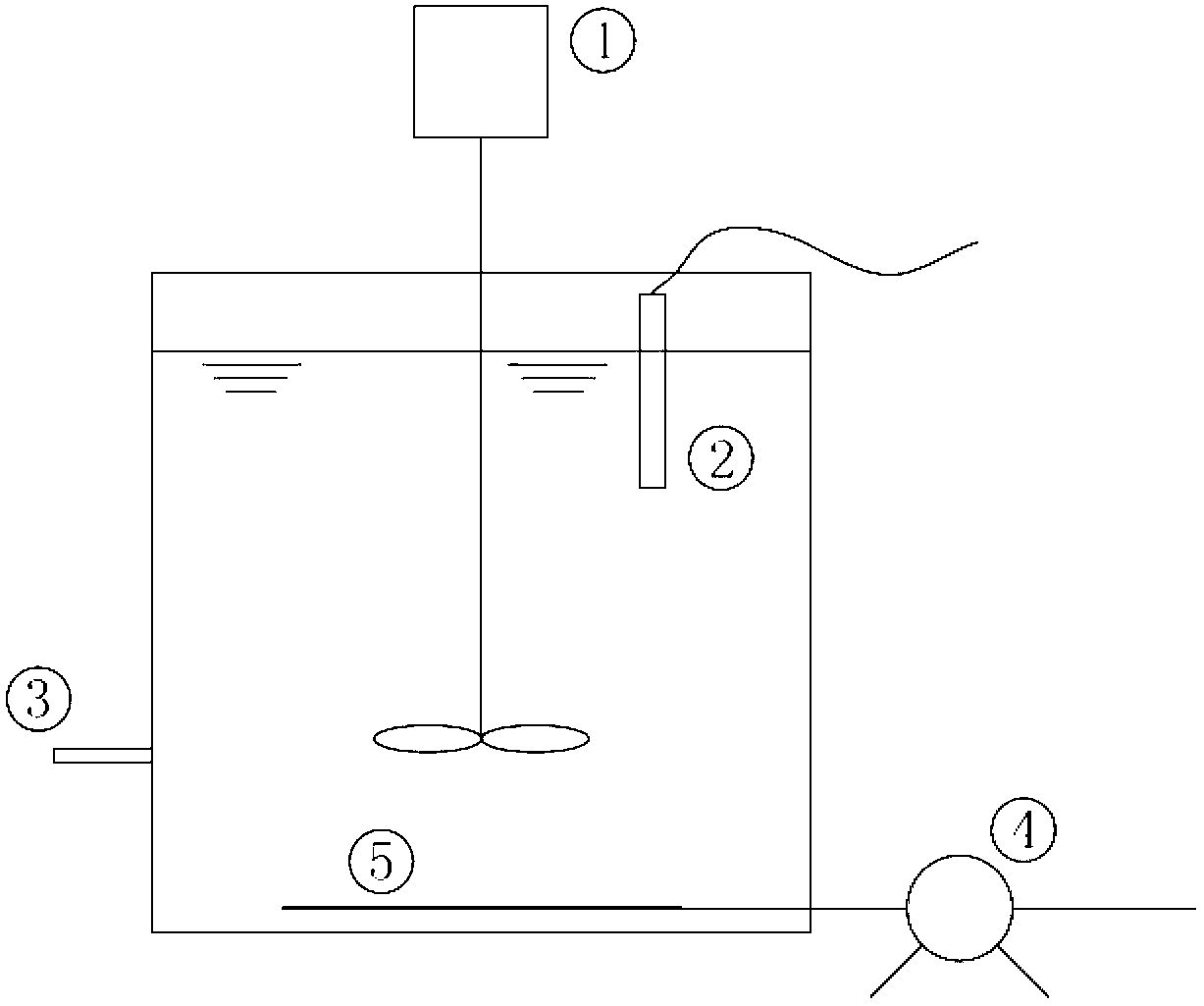

[0033] The reactor is a biological reaction tank made of plexiglass, with an inner diameter of 250mm, a height of 250mm, a total volume of 12L, and an effective volume of 10L. It adopts the sequence batch operation mode, with a stirring device inside and an aeration device at the bottom, and the aeration volume is controlled by a rotameter.

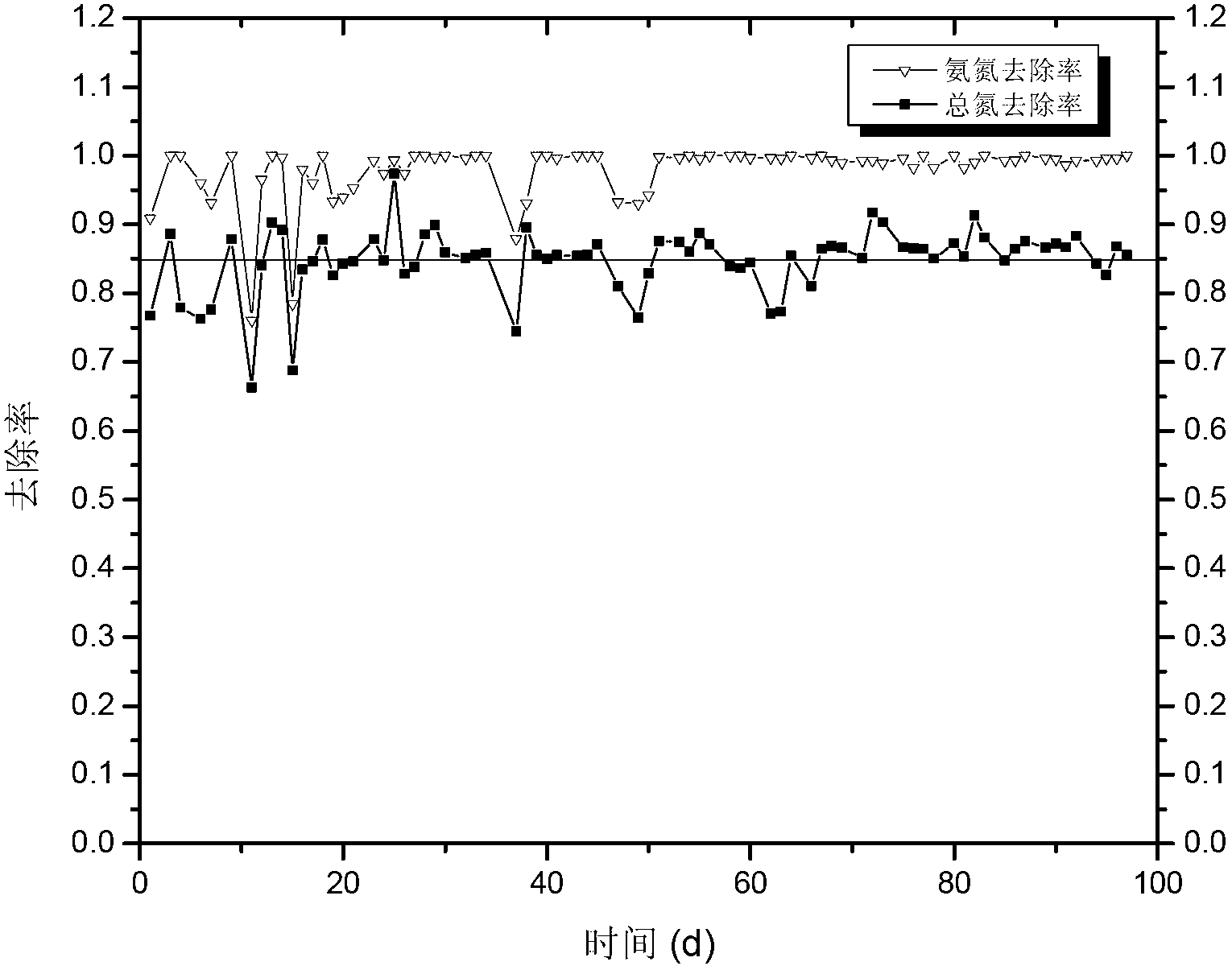

[0034] In the normal operation stage, the water exchange ratio is 0.7, the aeration rate is 0.2L / min, the temperature is 17-25°C, the pH is 8.0-8.2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com