Method for extracting hesperidin and synephrine from immature bitter oranges

A technology of hesperidin and citrus aurantium is applied in the field of separation of natural products to achieve the effects of low price, easy planting and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

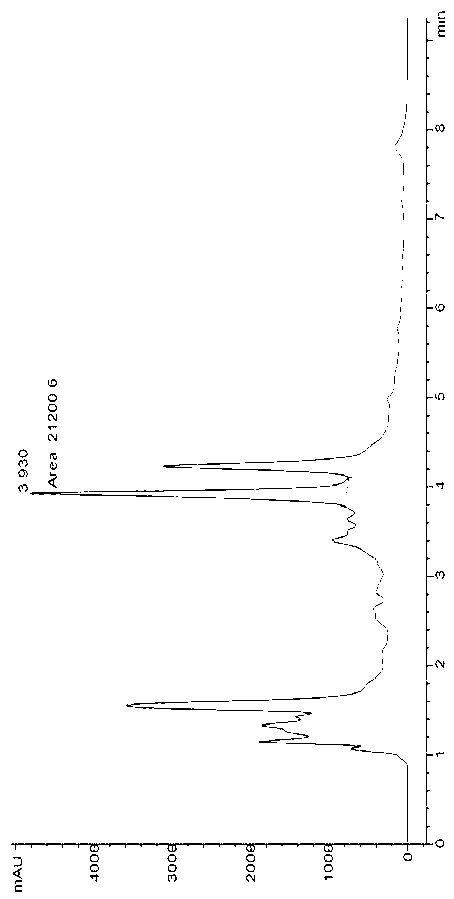

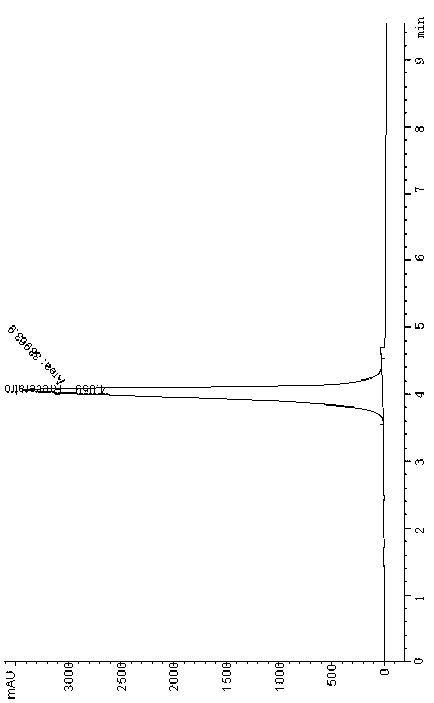

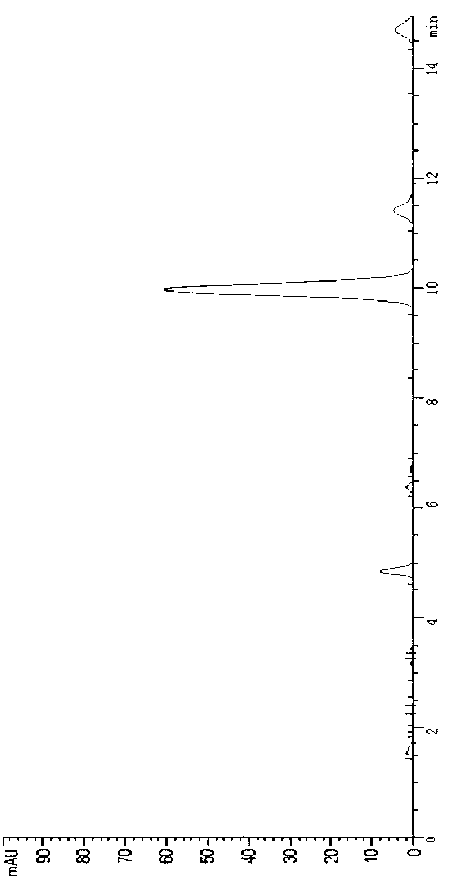

[0038] Choose Citrus aurantium with a synephrine content of 1.34% and a hesperidin content of 4.94%, dry it, crush it to below 10 mesh, weigh 100kg, add 400L of petroleum ether to mix, reflux at 70°C for 40min, and ceramic membrane Filtrate once to obtain the filtrate, and then concentrate under reduced pressure to remove petroleum ether to obtain Citrus aurantium essential oil. Mix the filter residue of Citrus aurantii with 250L of 20% ethanol aqueous solution, wherein the ethanol aqueous solution also contains 0.0001mol / L NaOH, mix, reflux and extract at 45°C for 40min, filter once with a ceramic membrane to obtain the filtrate, repeat once more, and combine the filtrate to obtain 400L of mixed extract. Concentrate the extract to obtain 50L concentrated solution I, which is adsorbed on KLFC-150 macroporous resin, and eluted with ethanol aqueous solution containing 40% ethanol and 0.001mol / L NaOH to obtain 120L eluent I, and The eluent I was concentrated under reduced pressur...

Embodiment 2

[0040] Choose the content of synephrine in Fructus Aurantium Fructus at 1.34%, the content of hesperidin at 4.94%, dry and pulverize Fructus Fructus Fructus Fructus Fructus Aurantii to below 10 orders and weigh 200kg, add 800L of aqueous solution containing 0.001mol / LNaOH, 45% ethanol to carry out Mix, reflux extraction at 40°C; mix Citrus aurantii filter residue with 400L of 20% ethanol aqueous solution, in which the ethanol aqueous solution also contains 0.0001mol / L NaOH, mix, reflux extraction at 45°C for 40min, filter once with a ceramic membrane to obtain filtrate, repeat once more, and combine The filtrate was mixed extract 700L. Concentrate the extract to obtain 80L concentrated solution I, which is adsorbed on KLFC-150 macroporous resin, and eluted with ethanol aqueous solution containing 40% ethanol and 0.001mol / L NaOH to obtain 250L eluent I, and The eluent I was concentrated under reduced pressure at 50°C to 25 L to obtain the concentrated solution II. Then, KLFC-1...

Embodiment 3

[0042] Choose the synephrine content in 1.34% and the hesperidin content in citrus citrus aurantium to be 4.94%, dry and pulverize the citrus aurantium to below 10 mesh and weigh 400kg, add 1400L containing 0.001mol / LNaOH, 45% ethanol aqueous solution to carry out Mix, reflux extraction at 40°C; mix Citrus aurantii filter residue with 500L of 20% ethanol aqueous solution, in which the ethanol aqueous solution also contains 0.0001mol / L NaOH, mix, reflux extraction at 45°C for 40min, filter once with a ceramic membrane to obtain filtrate, repeat once more, and combine The filtrate was mixed extract 900L. Concentrate the extract to obtain 100L concentrated solution I, which is adsorbed on KLFC-150 macroporous resin, and eluted with ethanol aqueous solution containing 40% ethanol and 0.001mol / L NaOH to obtain 450L eluent I, and The eluent I was concentrated under reduced pressure at 50°C to 50 L to obtain the concentrated solution II. Then, KLFC-150 macroporous resin was eluted w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com