Raw material composition of modified polyurethane material, and preparation method and application thereof

A technology of polyurethane material and raw material composition, which is applied in drilling compositions, polyurea/polyurethane adhesives, chemical instruments and methods, etc., can solve great hidden dangers of safety accidents, time-consuming filling materials, and difficult construction, etc. problems, to achieve huge social and economic benefits, reduce personnel, and improve mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

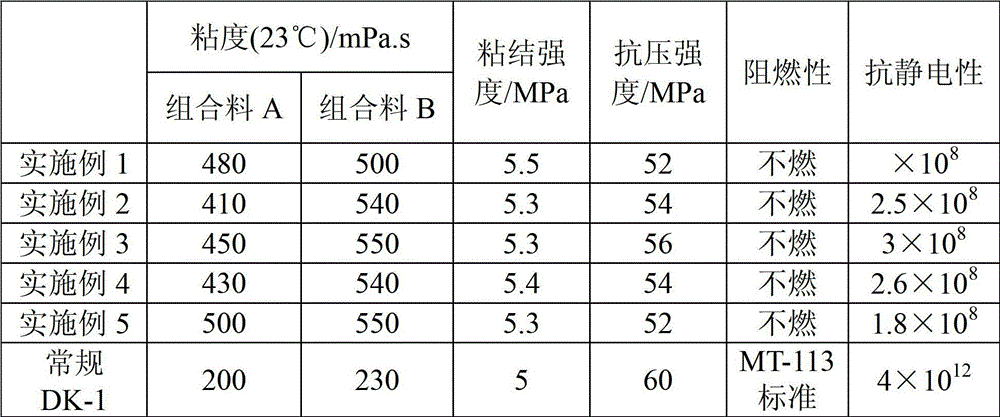

Examples

Embodiment 1

[0033] Combination material A:

[0034] DL-2000: 10

[0035] DL-1000: 9

[0036] Ethylene oxide modified silicone polymer: 80

[0037] Dibutyltin dilaurate: 1

[0038] Combination material B:

[0039] DL-400: 19.99999

[0040] PM200: 80

[0041] Phosphoric acid: 0.00001

[0042] Preparation of composite material A: Put the measured DL-2000, DL-1000, modifier, and dibutyltin dilaurate into the reaction kettle, stir at 40°C for 3 hours at a stirring speed of 100rpm, and then fill the barrel.

[0043] Preparation of composite material B: put DL-400 based on the formula into the reaction kettle at room temperature, raise it to 80°C, stir, vacuumize and dehydrate and degas for 3 hours, until the moisture content is below 0.05%, cool down to 40°C and add the measured For PM200, react at 85°C for 3 hours, cool down to 40°C, add measured phosphoric acid, stir well, and pack into barrels.

[0044] When using, mix A and compound B evenly according to the volume ratio of A:B=1:1,...

Embodiment 2

[0046] Combination material A:

[0047] DL-1000: 25

[0048] Ethylene oxide modified silicone polymer: 74.2

[0049] Dibutyltin dilaurate: 1

[0050] Combination material B:

[0051] MN-303: 9.99999

[0052] PM200: 90

[0053] Benzoyl chloride: 0.00001

[0054] Preparation of composite material A: Put the measured DL-1000, modifier, and dibutyltin dilaurate into the reaction kettle, stir at 15°C for 3 hours at a stirring speed of 150rpm, and then pack into barrels.

[0055] Preparation of composition B: Put the MN-303 based on the formula into the reaction kettle at room temperature, raise it to 100°C, stir, vacuumize and dehydrate and degas for 2 hours, until the moisture content is below 0.05%, cool down to 10°C and add the measured PM200, react at 80°C for 2 hours, cool down to 10°C, add measured benzoyl chloride, stir well, and pack into barrels.

[0056] When using, mix A and compound B evenly according to the volume ratio of A:B=1:1, and inject it into rock formatio...

Embodiment 3

[0058] Combination material A:

[0059] DL-2000: 39

[0060] Ethylene oxide modified silicone polymer: 60

[0061] Dibutyltin dilaurate: 1

[0062] Combination material B:

[0063] DL-1000: 19.99999

[0064] 44V20: 80

[0065] Benzoyl chloride: 0.00001

[0066] Preparation of composite material A: Put the measured DL-2000, modifier, and dibutyltin dilaurate into the reaction kettle, stir at 30°C at a stirring speed of 115rpm for 4 hours, and then pack into barrels.

[0067] Preparation of composite material B: Put DL-400 based on the formula into the reaction kettle at room temperature, raise it to 90°C, stir, vacuumize and dehydrate and degas for 2.5 hours, until the moisture content is below 0.05%, cool down to 20°C and add the measured 44V20, react at 80°C for 3 hours, cool down to 30°C, add the measured benzoyl chloride, stir well, and pack into barrels.

[0068] When using, mix A and compound B evenly according to the volume ratio of A:B=1:1, and inject it into roc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com