Tung-oil-based waterborne polyurethane and preparation method thereof

A technology of water-based polyurethane and tung oil, applied in polyurea/polyurethane coatings, coatings, etc., to achieve the effects of simple coating operation, poor water resistance and poor film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

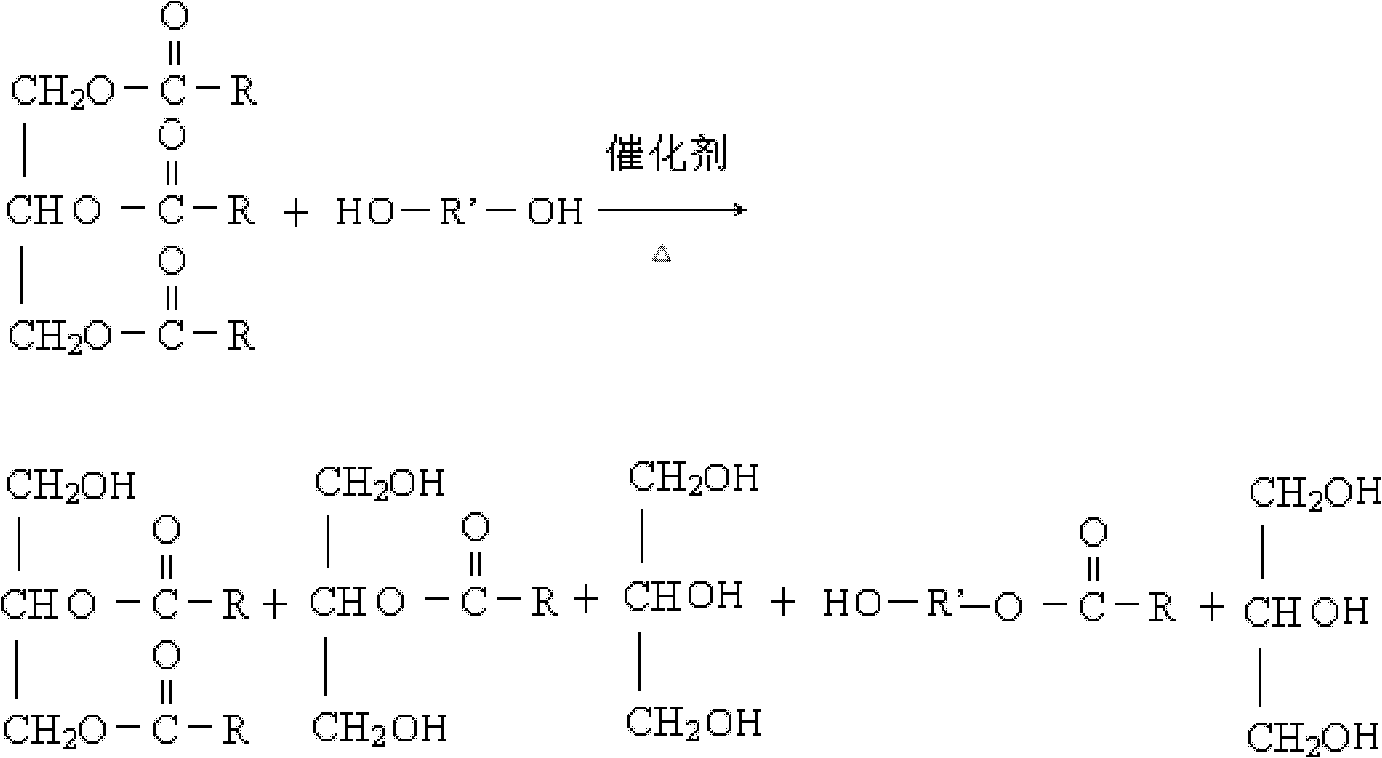

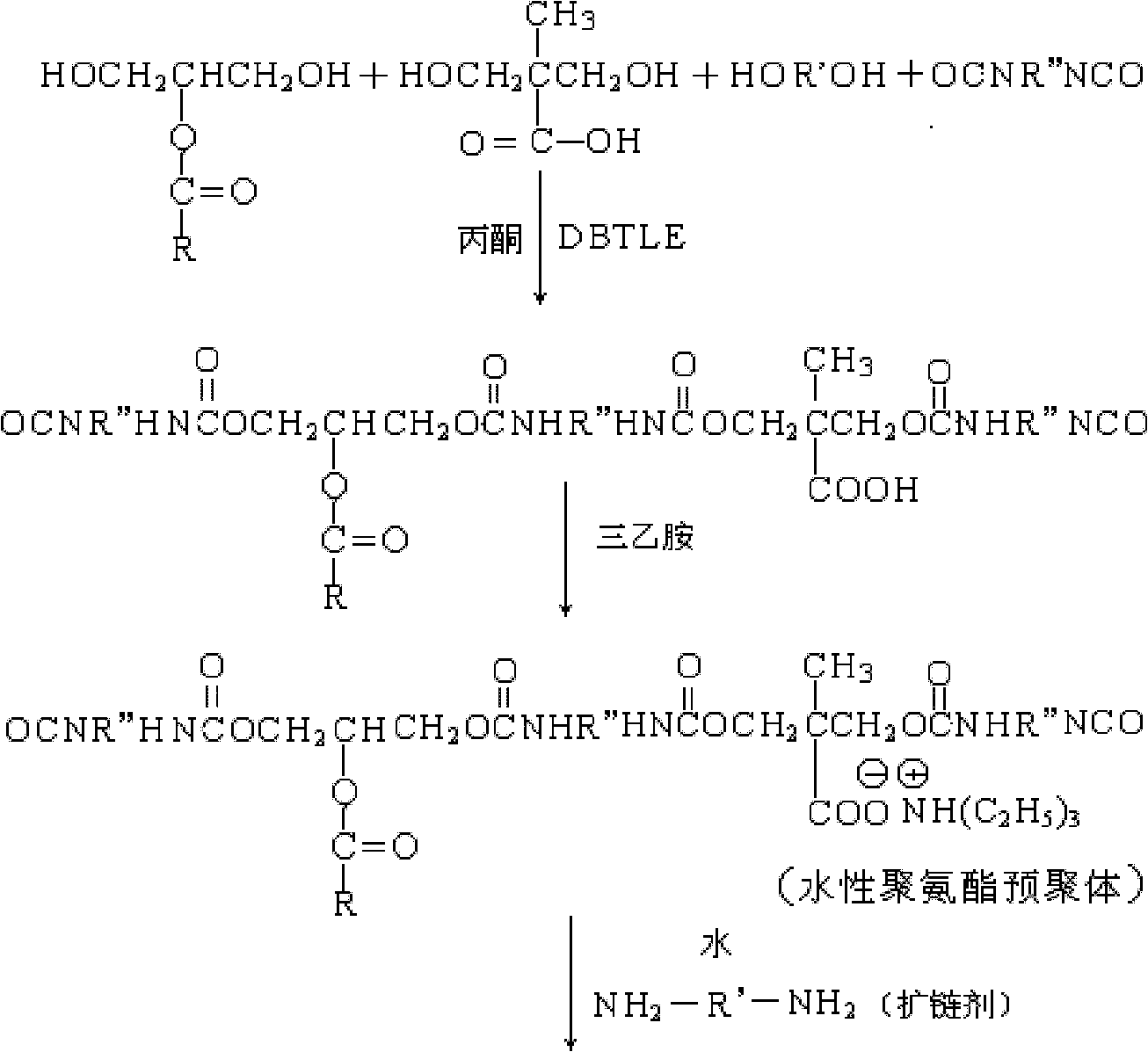

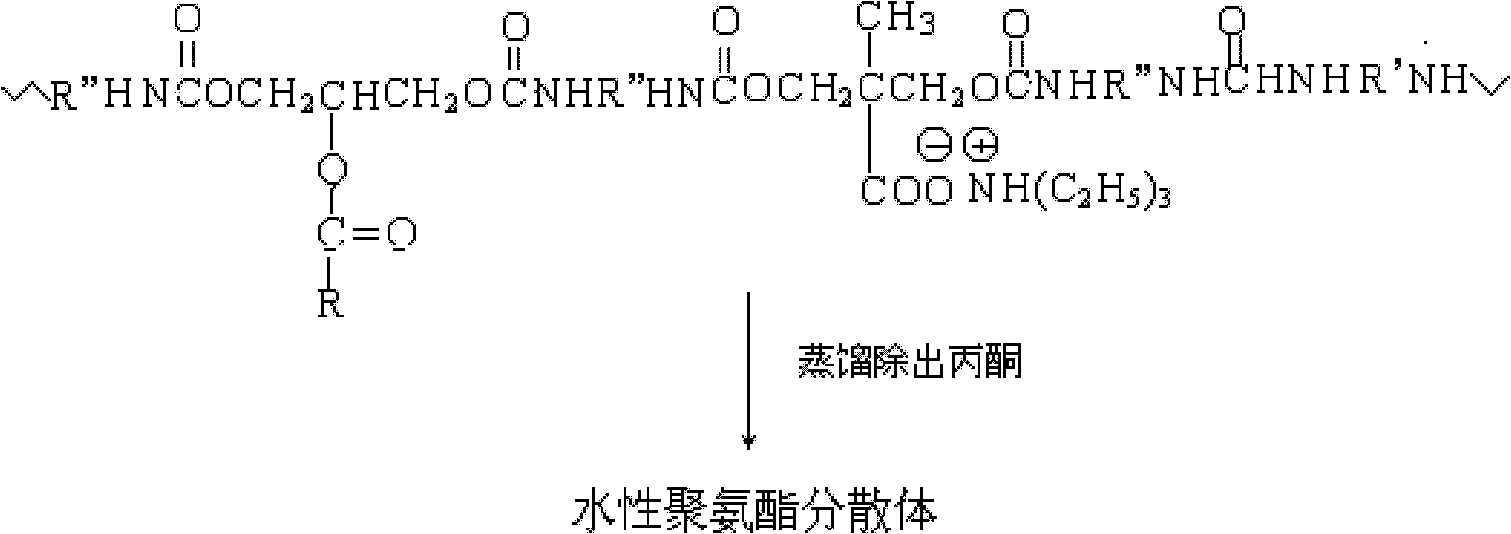

Method used

Image

Examples

Embodiment 1

[0025] Raw materials: tung oil (industrial product, dried with anhydrous magnesium sulfate before use), ethylene glycol (chemically pure, vacuum dried for 2 hours before use), p-toluenesulfonic acid (chemically pure), pol-1256 (industrial product, Hydroxyl content: 1.0mmo / g), toluene-2,4-diisocyanate (chemically pure), dibutyltin dilaurate (analytical grade), acetone (before use, dried with anhydrous magnesium sulfate and distilled under reduced pressure) , Triethylamine (chemically pure), dimethylolpropionic acid (industrial product, vacuum dried before use), ethylenediamine (chemically pure), deionized water.

[0026] 1. Preparation of Modified Tung Oil

[0027] Formulation (by weight)

[0028] Tung Oil 432 servings

[0029] Ethylene glycol 120 parts

[0030] 6 parts p-toluenesulfonic acid

[0031] The specific preparation method is:

[0032] Weigh 120 parts of ethylene glycol and add it to a four-necked flask with a thermometer, a reflux condenser (shared with the nitr...

Embodiment 2

[0038] Raw materials: tung oil (industrial product, dried with anhydrous manganese sulfate before use), 1,4-butanediol (chemically pure, vacuum dried for 2 hours before use), potassium hydroxide (analytical grade), pol-1256 ( Industrial product, hydroxyl content: 1.0mmo / g), isophorone diisocyanate (chemically pure), dibutyltin dilaurate (analytical grade), acetone (before use, dried with anhydrous magnesium sulfate, distilled under reduced pressure ), triethylamine (chemically pure), dimethylolpropionic acid (industrial product, vacuum dried before use), isophoronediamine (chemically pure), deionized water.

[0039] 1. Preparation of Modified Tung Oil

[0040] Formulation (by weight)

[0041] Tung Oil 432 servings

[0042] 1,4-Butanediol 180 parts

[0043] 5 parts potassium hydroxide

[0044] The specific preparation method is:

[0045]Weigh 180 parts of 1,4-butanediol and add it to a four-necked flask with a thermometer, a reflux condenser (shared with the nitrogen inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com