Production technology for fermentatively producing proteinase K by utilizing fungi microorganisms

A technology of microbial fermentation and production process, applied in the field of microbial fermentation of proteinase K, can solve the problems of low unit output, application limitation, high production cost, etc., and achieve the effect of meeting market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

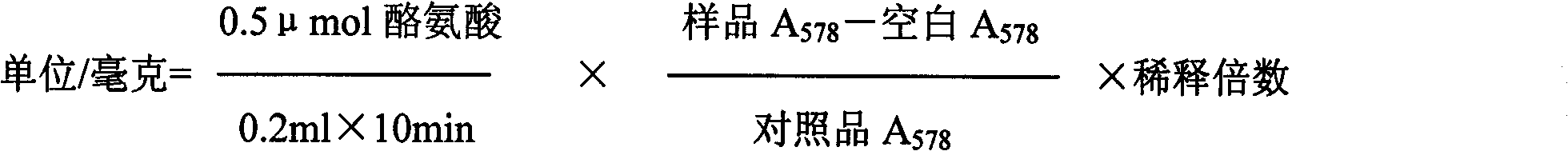

Method used

Image

Examples

Embodiment 1

[0055] adopted through 60 The mutant strain IMU-112 obtained by Go gamma ray mutagenesis and protoplast ultraviolet mutagenesis is the starting bacterium. Pick 2 rings of the bacterium preserved on the slant with an inoculation loop and put it into a 1000ml Erlenmeyer flask containing 200ml of primary seed medium , A total of 3 bottles were inoculated. Regulate medium pH to be 5.5, shaker speed 180rev / min, after cultivating 44h at 28 ℃, inoculate in the 10L fermentor that 6 liters of secondary seed mediums are housed with 8% inoculum size, in the cultivation process, Control pH to 5.5, temperature to 28°C, ventilation rate to 1.2vvm, stirring speed to 350rev / min, continuous culture for 44 hours, then inoculate 7.5% inoculum into a 100L fermenter with a liquid capacity of 80L, and control the fermentation pH The temperature was 5.5, the temperature was 28°C, the ventilation rate was 1.0vvm, and the stirring speed was 350rev / min, and the fermented liquid was harvested for 64 ho...

Embodiment 2

[0057] adopted through 60 The mutant strain IMU-112 obtained by Go gamma ray mutagenesis and protoplast ultraviolet mutagenesis was selected as the starting bacterium. Pick 2 rings of the bacterium preserved on the slant with an inoculation loop and put it into a 1000ml Erlenmeyer flask containing 150ml of primary seed medium. , A total of 4 bottles were inoculated. Regulate medium pH to be 5.8, shaker speed 190rev / min, after cultivating 40h at 26 ℃, inoculate in the 10L fermentor that 5 liters of secondary seed culture medium are housed with 10% inoculum size, in the cultivation process, Control pH to 5.8, temperature to 26°C, ventilation rate to 1.2vvm, stirring speed to 280rev / min, continuous culture for 40h, and then inoculate 6% of the inoculum into a 100L fermenter with a liquid volume of 85L, and control the fermentation pH The temperature was 5.8, the temperature was 26°C, the ventilation rate was 1.0vvm, and the stirring speed was 400rev / min, and the fermentation liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com