Method for preparing phenol-formaldehyde resins, resin materials and method for preparing resin molding materials

A phenolic resin and phenolic technology, applied in the field of preparation of phenolic resin, can solve the problems of endangering the living environment of human beings, warming, limited oil reserves, etc., and achieve the effects of reducing carbon dioxide emissions, slowing down global warming, and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] [Example 1] Preparation I of resin molding material of the present invention

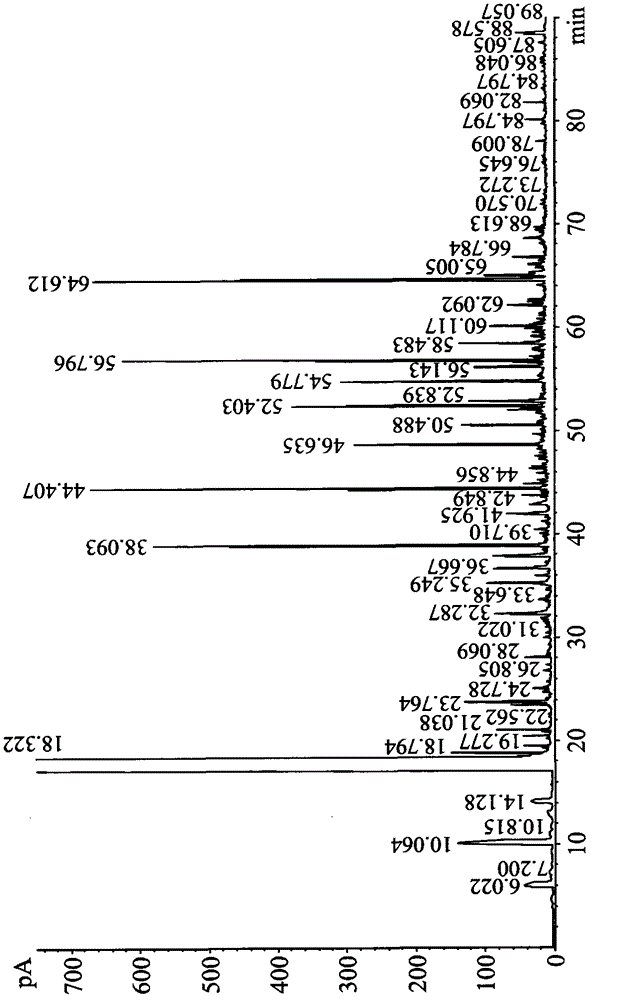

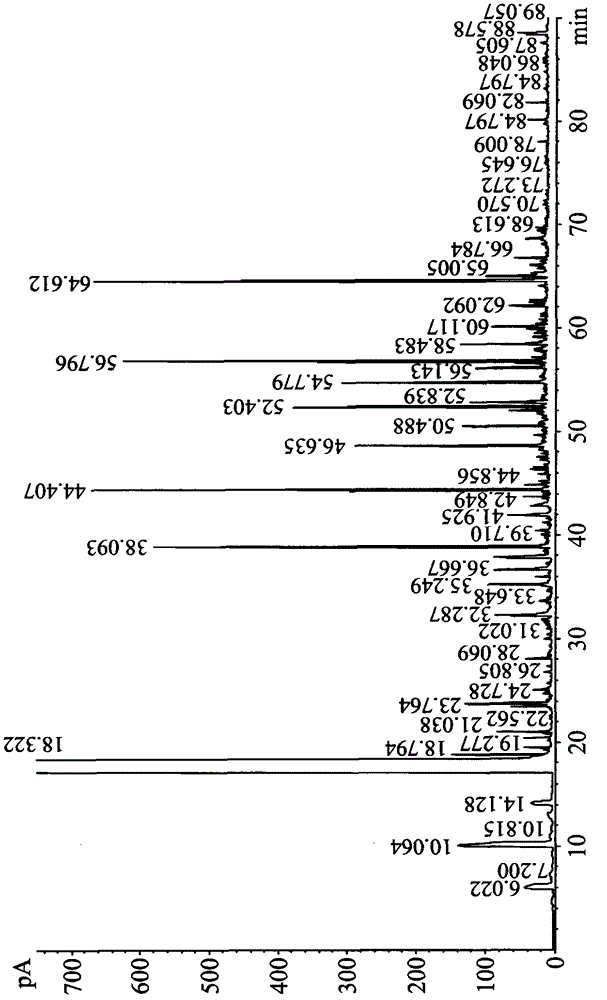

[0034] First, get 525 grams of cedar pyrolysis oil (this cedar pyrolysis oil can refer to Chih-Chiang Chang, et al., "Fast Pyrolysis of Sawdust in a Bubbling Fluidized Bed to Produce Bio-oil", The 13th Asia Pacific Confederation of Chemical Engineering Congress, October 5-8, 2010, produced in Taipei) adding 420 grams of ethyl acetate for extraction. The above mixed solution was first filtered, and the obtained filtrate was left to separate phases with a separatory funnel. Next, take 581 grams of the solvent phase and add 418 grams of water for washing. After static phase separation, 470 grams of the hydrophobic phase was taken, and 471 grams of 5% sodium bicarbonate was added to adjust its pH to about 7.7. The above-mentioned neutralized solution was left to stand for phase separation, and the hydrophobic phase was evaporated by a rotary evaporator to obtain a phenolic compound sample. The...

Embodiment 2

[0048] [Example 2] Preparation II of the resin molding material of the present invention

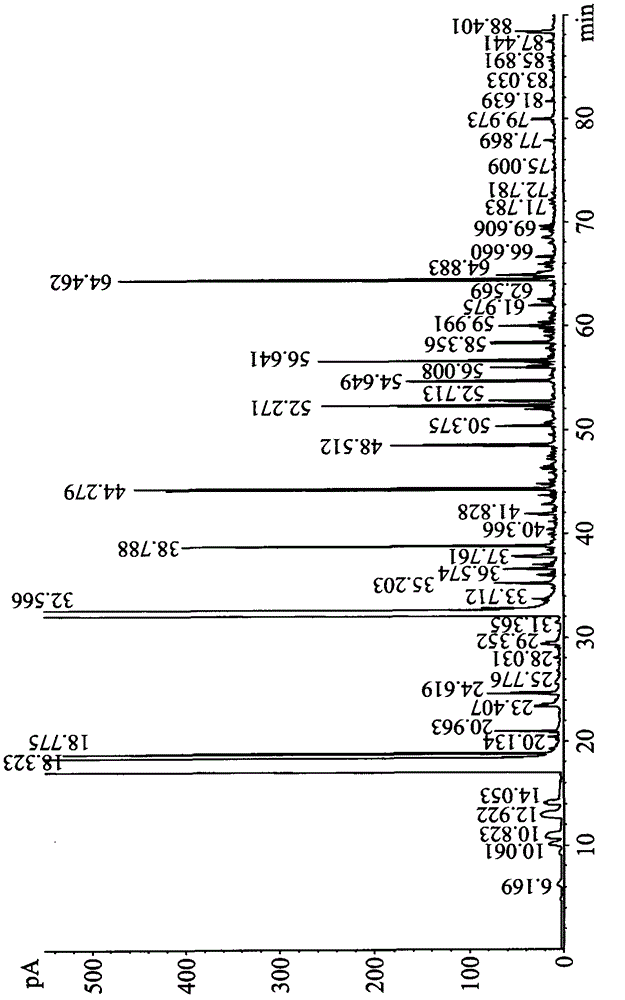

[0049] First, get 479 grams of cedar pyrolysis oil and add 48 grams of ethyl acetate and 105 grams of phenol (cedar pyrolysis oil / ethyl acetate=1 / 0.1, biomass pyrolysis oil / phenol=1 / 0.22 ) for extraction, and after the extraction mixture was filtered, the resulting filtrate was allowed to stand for stratification with a separatory funnel. Next, take 435.5 grams of the solvent phase and add 357.34 grams of water to wash it with water. After statically separating the phases, 309 grams of the hydrophobic phase was added to 412 grams of 5% sodium bicarbonate to adjust its pH to about 7.3. The above-mentioned neutralized solution was left to stand for phase separation, and the hydrophobic phase was evaporated with a rotary evaporator to obtain the first phenolic mixture sample. Take the first phenolic mixture sample and add 3 times of MIBK for dilution, and analyze its composition by GC. G...

Embodiment 3

[0065] [Example 3] Reactive phenol content in the extract of the present invention (extractant is ethyl acetate)

[0066] The standard method for testing the content of reactive phenols is to add formalin to the aqueous solution of the phenolic substance sample, and make the phenolic substance and formaldehyde undergo polycondensation reaction in a strong acid environment to form a polymerized solid substance and precipitate it. The final product was dried in an oven at 103±2°C until constant weight. Finally, the reactive phenol content was calculated from the sample weight taken and the final dry weight.

[0067] The stock solution of cedar pyrolysis oil was separated by standing, and the reactive phenol content of the oil phase was tested to be 58%.

[0068] The procedure for separating phenolic compounds from cedar wood pyrolysis oil is the same as in Example 1, including extraction, water washing, neutralization and evaporation. The extractant is ethyl acetate, cedar pyr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com