BiVO4/Bi2WO6 composite semiconductor material as well as hydrothermal preparation method and application thereof

A compound semiconductor and preparation process technology, applied in the field of BiVO4/Bi2WO6 compound semiconductor material and its hydrothermal preparation, can solve the problems of narrow absorption range in the visible light region, fast photogenerated carrier recombination rate, etc. The effect of controllable bulk structure and morphology and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

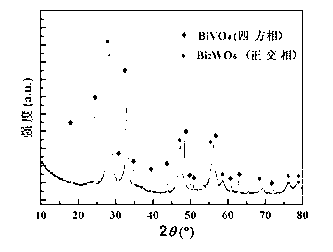

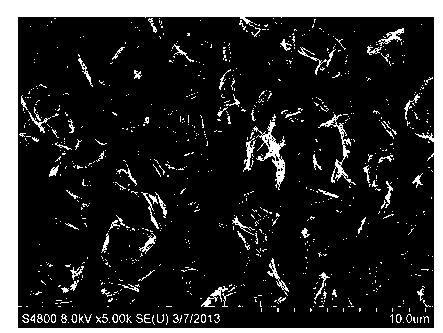

[0029]BiVO of the present invention 4 / Bi 2 WO 6 A compound semiconductor material with a nominal composition of (1-x)BiVO 4 / xBi 2 WO 6 , where x=50mol% (x represents Bi 2 WO 6 accounted for the mole percent of the system). Its concrete preparation steps are as follows:

[0030] a) Weigh 1mmol (0.1170g) of NH 4 VO 3 Dissolve 0.2550g ammonium tungstate in 10mL 2mol / L NaOH solution to make transparent solution A;

[0031] b) Weigh 1.4553g of Bi(NO 3 ) 3 ·5H 2 O dissolved in 10mL2mol / L HNO 3 A transparent solution B is made in the solution;

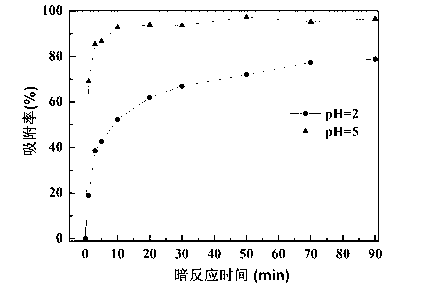

[0032] c) Gradually add the above-mentioned solution A to the solution B dropwise under constant stirring to form a suspension, continue stirring for 1 hour after the addition is complete, and then adjust the pH value of the system to 5 with 2mol / L NaOH solution. Continue stirring for 2h to obtain a precursor solution;

[0033] d) Transfer the precursor solution prepared above to a stainless steel reaction kettle lined with ...

Embodiment 2

[0035] BiVO of the present invention 4 / Bi 2 WO 6 A compound semiconductor material with a nominal composition of (1-x)BiVO 4 / xBi 2 WO 6 , where x=50mol% (x represents Bi 2 WO 6 Accounting for the molar percentage of the system), its specific preparation steps are as follows:

[0036] a) Weigh 1mmol (0.1170g) of NH 4 VO 3 Dissolve 0.2550g ammonium tungstate in 10mL 2mol / L NaOH solution to make transparent solution A;

[0037] b) Weigh 1.4553g of Bi(NO 3 ) 3 ·5H 2 O dissolved in 10mL2mol / L HNO 3 A transparent solution B is made in the solution;

[0038] c) Gradually add the above-mentioned solution A into the solution B dropwise under constant stirring to form a suspension, continue stirring for 1 hour after the addition is complete, and then adjust the pH value of the system to 2 with 2mol / L NaOH solution. Continue stirring for 2h to obtain a precursor solution;

[0039] d) Transfer the precursor solution prepared above to a stainless steel reaction kettle line...

Embodiment 3

[0041] BiVO of the present invention 4 / Bi 2 WO 6 A compound semiconductor material with a nominal composition of (1-x)BiVO 4 / xBi 2 WO 6 , where x=10mol% (x represents Bi 2 WO 6 Accounting for the molar percentage of the system) its specific preparation steps are as follows:

[0042] a) Weigh 2mmol (0.2336g) NH 4 VO 3 Dissolve 0.0566g ammonium tungstate in 10mL 2mol / L NaOH solution to make transparent solution A.

[0043] b) Weigh 1.1856g of Bi(NO 3 ) 3 ·5H 2 O dissolved in 10mL2mol / L HNO 3 A transparent solution B is made in the solution;

[0044] c) Gradually add the above-mentioned solution A into the solution B dropwise under constant stirring to form a suspension, continue stirring for 1 hour after the addition is complete, and then use 2mol / L NaOH solution to adjust the pH value of the system to 3, Continue stirring for 3h to obtain a precursor solution;

[0045] d) Transfer the precursor solution prepared above to a stainless steel reaction kettle lined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com