Welding-synchronizing magnetic control device based on singlechip control and control method

A single-chip microcomputer control and magnetic control device technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of inability to realize synchronous control of the welding process, control accuracy and flexibility limitations, and achieve changes in the flow of liquid metal. Small electromagnetic interference and the effect of preventing surge current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

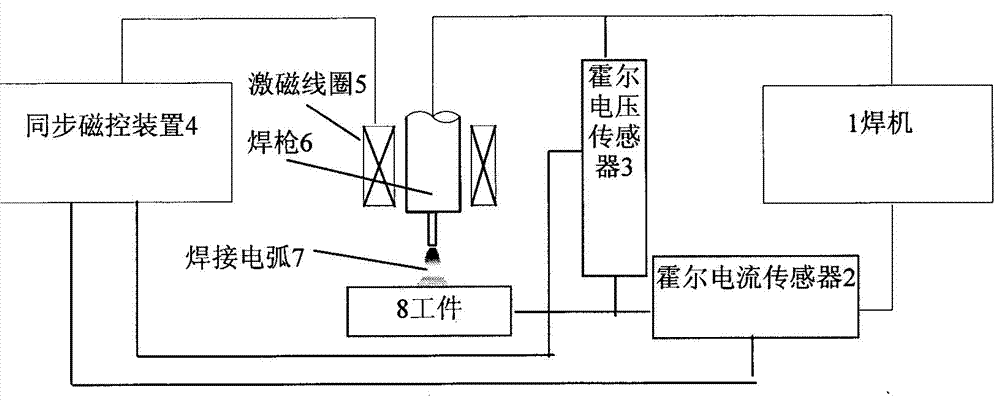

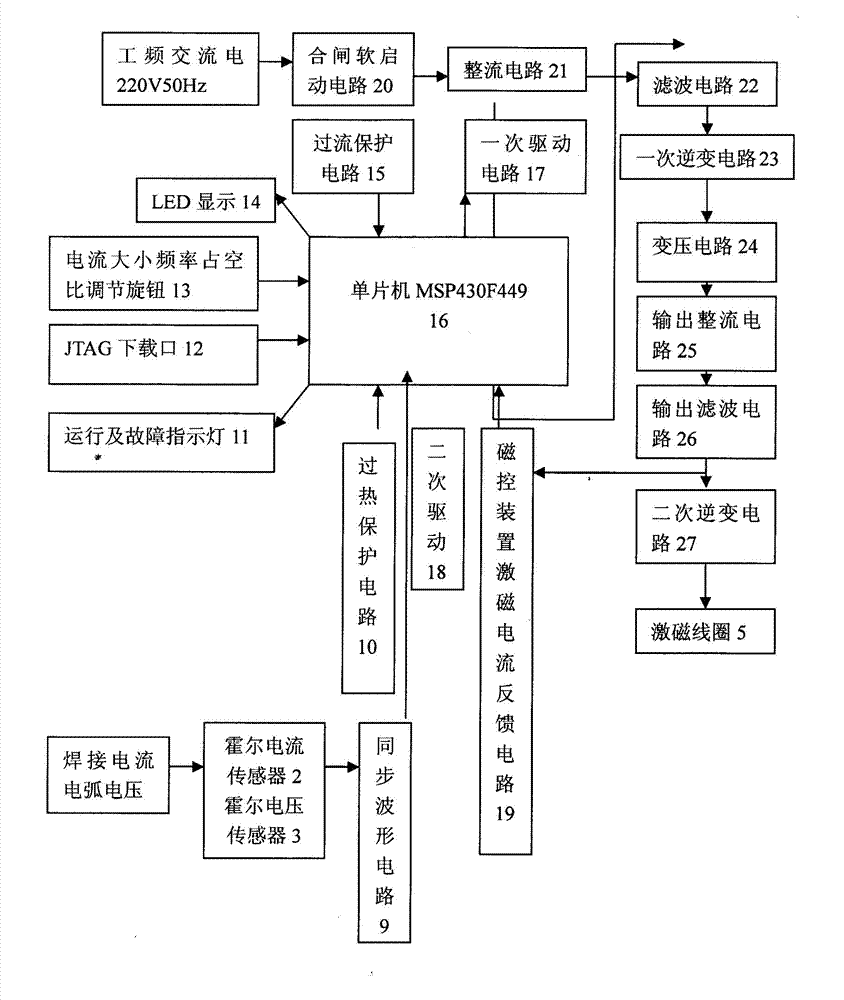

[0036] figure 1 , figure 2Among them, 1 welding machine, 2 Hall current sensor, 3 Hall voltage sensor, 4 synchronous magnetic control device, 5 excitation coil, 6 welding torch, 7 welding arc, 8 workpiece, 9 synchronous waveform circuit, 10 overheat protection circuit, 11 operation and fault indicator light, 12 JTAG download port, 13 synchronous mode adjustment knob, 14 LED display, 15 overcurrent protection circuit, 16 single chip microcomputer (MSP430F449), 17 primary drive circuit, 18 secondary drive circuit, 19 magnetron excitation current feedback Circuit 20 Closing soft start circuit, 21 Rectifier circuit, 22 Filter circuit, 23 Primary inverter circuit, 24 Transformer circuit, 25 Output rectifier circuit, 26 Output filter circuit, 27 Secondary inverter circuit

[0037] A single-chip microcomputer synchronous magnetic field control method for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com