Titanium alloy and stainless steel electron beam welding filler material, preparation process and method thereof

A technology of electron beam welding and filling materials, which is applied in the direction of electron beam welding equipment, welding/cutting media/materials, welding equipment, etc., can solve the problems of difficult to obtain high-strength joints, metallurgical incompatibility physical properties, etc., to avoid A large amount of melting, increasing the range of welding speed, and good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

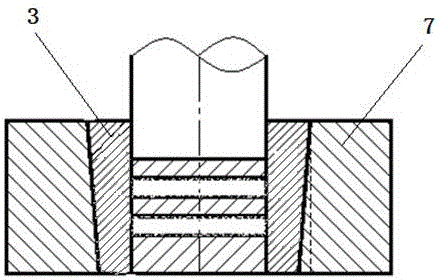

[0029] The preparation process steps of the copper-chromium alloy layer 3 of the present invention are as follows:

[0030] 1. Weigh a certain mass of unoxidized Cu powder, Cr powder, Ni powder and Ti powder according to the mass percentage in a glove box filled with argon, and place them in a ball mill tank equipped with steel balls with different diameters. The tank is filled with argon gas at an atmospheric pressure to avoid powder oxidation, the ball mill tank is sealed, and the ball mill tank is placed on a planetary ball mill for ball milling and mixing.

[0031] 2. The alloy mixed uniformly by the ball mill is placed in a graphite mold with a certain strength under the protection of argon, and the draft angle of the graphite mold is preferably 1.5°, and hot-pressed and sintered in a vacuum hot-pressed sintering furnace , Preparing copper-chromium alloy plates with heat preservation under constant pressure to ensure higher density of the alloy and help to eliminate pores...

Embodiment 1

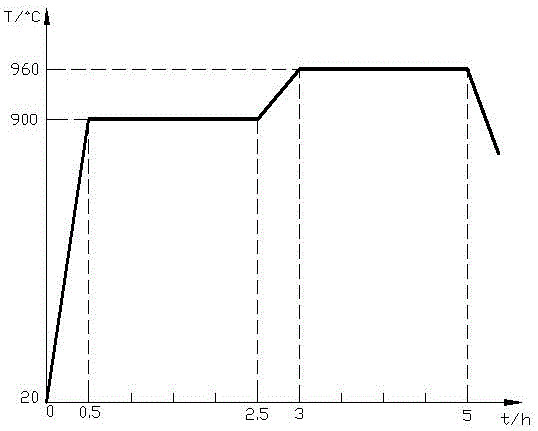

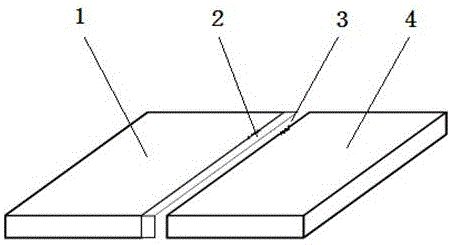

[0038] Example 1: 1. Preparation of filling materials: In a glove box full of argon, take by weight 50% of unoxidized 500 mesh chromium powder, 2% of 350 mesh nickel powder, 3% of 350 mesh titanium powder and 200 mesh The copper powder is 45%, and the purity of each powder reaches 99.95%. It is placed in a ball mill tank equipped with steel balls with different diameters. The ball-to-powder ratio in the ball ink tank is 20:1. Argon, in order to avoid powder oxidation, seal the ball mill tank, put the ball mill tank on the planetary ball mill for ball milling and mixing, the ball milling speed is 700r / min, the ball milling time is 18h, the alloy after the ball mill is evenly mixed is protected by argon Place in the graphite mold 7 that has certain intensity below, and the draft angle of graphite mold 7 is preferably 1.5 °, by figure 1 As shown, it was hot-pressed and sintered in a vacuum hot-pressed sintering furnace. The sintering pressure was kept at 30Mpa, the initial sinter...

Embodiment 2

[0040] Example 2: 1. Preparation of filling materials: In a glove box full of argon, take by weight 50% of unoxidized 400 mesh chromium powder, 2% of 500 mesh nickel powder, 3% of 500 mesh titanium powder and 400 mesh The copper powder is 45%, and the purity of each powder reaches 99.96%. It is placed in a ball mill tank equipped with steel balls with different diameters. The ball-to-powder ratio in the ball ink tank is 30:1. Argon, in order to avoid powder oxidation, seal the ball mill tank, put the ball mill tank on the planetary ball mill for ball milling and mixing, the ball milling speed is 600r / min, the ball milling time is 48h, the alloy after the ball mill is evenly mixed is protected by argon Place it in a graphite mold 7 with a certain strength, and the draft slope of the graphite mold 7 is preferably 1.5°, and it is formed by hot pressing and sintering in a vacuum hot pressing sintering furnace, and the sintering pressure is maintained at 40Mpa, such as figure 2 As...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com