Preparation method of europium-doped aluminum phosphate mesoporous glass

An aluminum phosphate mesoporous and glass technology, applied in the field of luminescent glass, can solve the problems of poor composition repeatability, many impurities in porous glass, and inability to accurately control the bound state of rare earth ions, and achieve good mesoporous properties and low refractive index. , the effect of excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

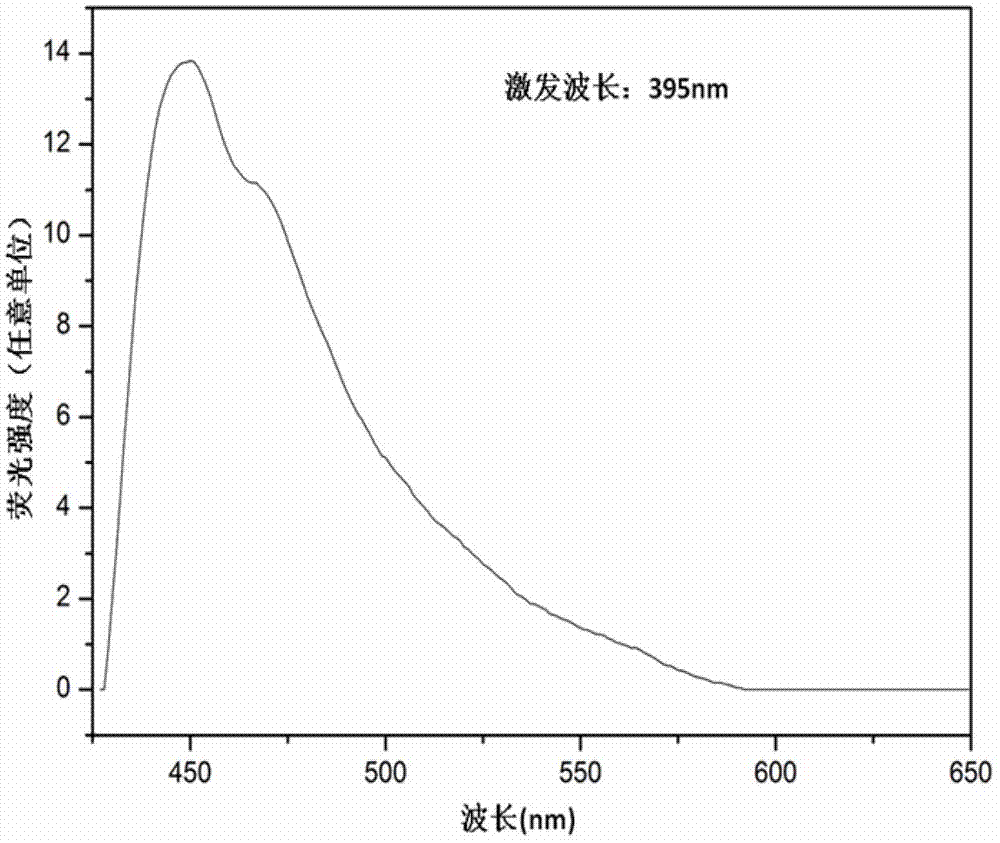

[0031] Use an analytical balance to weigh 0.0045g of analytically pure europium nitrate hexahydrate, dissolve it in 10ml of distilled water, and configure it to contain 0.001mol / L Eu 3+ impregnation solution. Immerse the aluminum phosphate glass in the immersion solution for 30 minutes, then take out the glass, put the dried sample in a corundum crucible for heat treatment in a muffle furnace, and raise the temperature from room temperature to 800°C at a rate of 0.5°C / min in an air atmosphere. And keep it warm at 800°C for 6 hours, then cool the glass to room temperature with the furnace and take it out to get europium-doped mesoporous aluminophosphate glass. figure 1 The emission spectrum of the glass prepared in Example 1 under the excitation of excitation light with a wavelength of 395 nm. Figure 7 The luminous chromaticity of the glass obtained in this embodiment is marked in the chromaticity diagram, and its color coordinates are (0.15, 0.14).

Embodiment 2

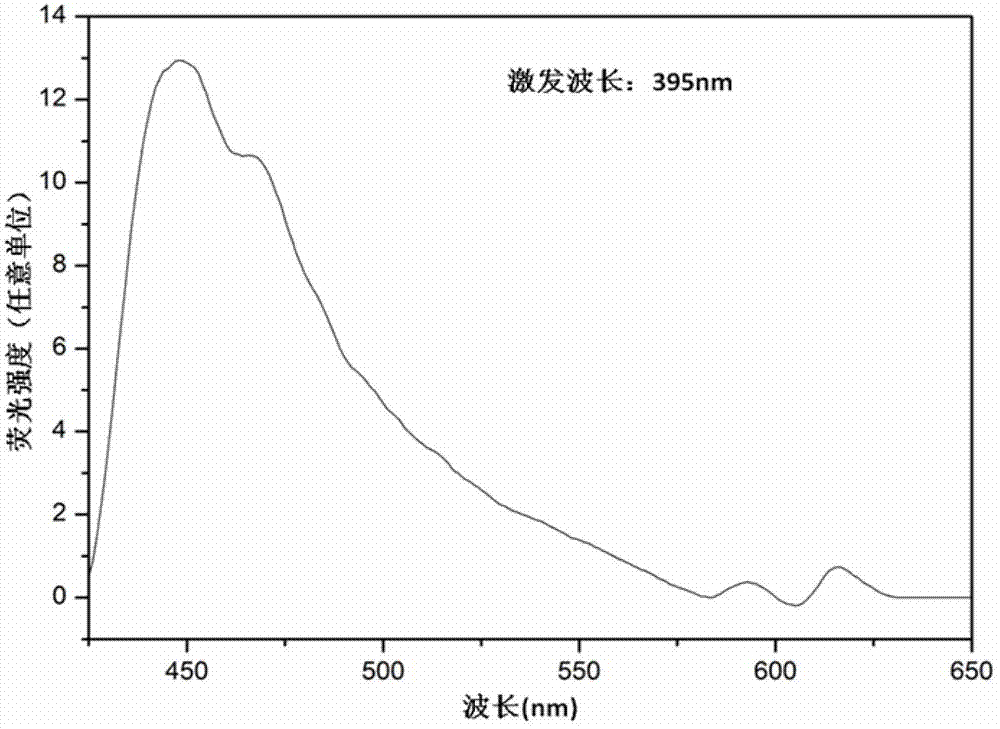

[0032] Example 2: Use an analytical balance to weigh 0.0352 g of analytically pure europium oxide and dissolve it in 1 mol / L dilute hydrochloric acid to prepare 10 ml containing 0.02 mol / L Eu 3+ impregnation solution. Immerse the aluminum phosphate glass in the immersion solution for 30 minutes, then take out the glass, put the dried sample into a muffle furnace for heat treatment with a corundum crucible, and heat it from room temperature to 400°C at a heating rate of 0.5°C / min under a nitrogen atmosphere. And keep it at 400°C for 5 hours, cool the glass to room temperature with the furnace and take it out to get europium-doped mesoporous aluminophosphate glass. figure 2 The emission spectrum of the glass prepared in Example 2 under the excitation of excitation light with a wavelength of 395 nm. Figure 7 The luminous chromaticity of the glass obtained in this embodiment is marked in the chromaticity diagram, and its color coordinates are (0.20, 0.17).

Embodiment 3

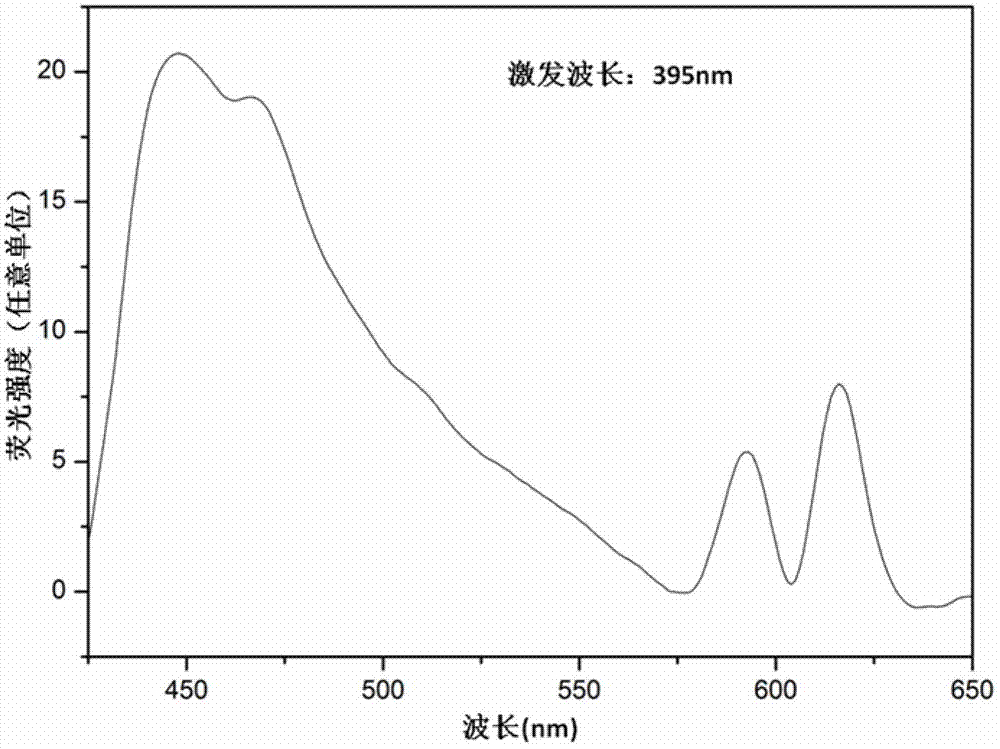

[0033] Example 3: Use an analytical balance to weigh 0.0352 g of analytically pure europium oxide dissolved in 1 mol / L dilute nitric acid, and prepare 10 ml containing 0.02 mol / L Eu 3+ impregnation solution. Immerse the aluminum phosphate glass in the immersion solution for 3 hours, then take out the glass, put the dried sample in a corundum crucible for heat treatment in a muffle furnace, and heat it from room temperature to 800°C at a heating rate of 5°C / min in an air atmosphere. And keep it at 800°C for 5 hours, cool the glass to room temperature with the furnace and take it out to get europium-doped mesoporous aluminophosphate glass. image 3 The emission spectrum of the glass prepared for Example 3 under the excitation of excitation light with a wavelength of 395 nm. Figure 7 The luminescence chromaticity of the glass obtained in this embodiment is marked in the chromaticity diagram, and its color coordinates are (0.34, 0.22).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com