Fly ash glass/ceramic composite coating and preparation method thereof

A technology of ceramic composite and fly ash, which is applied in the field of coating preparation and fly ash, can solve the problems of insufficient technology maturity and achieve the effect of simple process, low cost and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

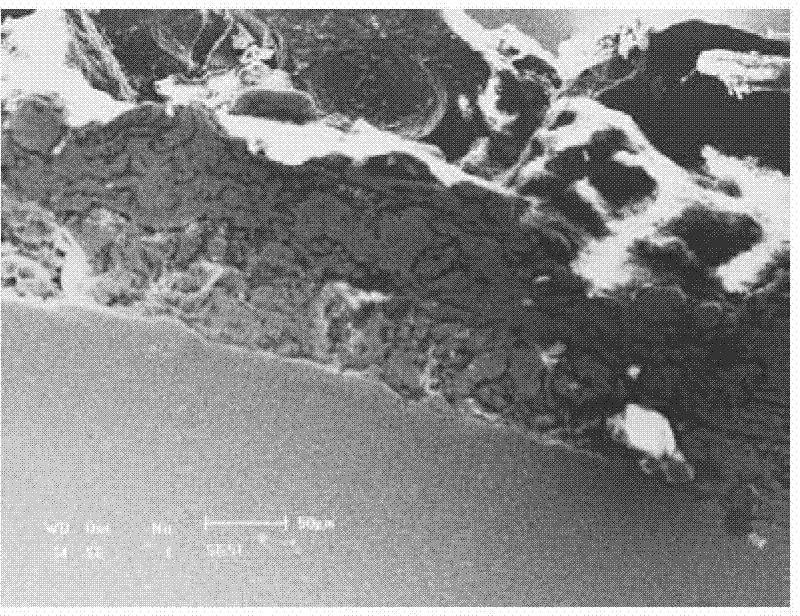

[0029] The invention provides a fly ash glass / ceramic composite coating and a preparation method thereof. The glass / ceramic composite coating is prepared on a Q235 steel substrate. The preparation method uses fly ash as raw material, and adds some additives, adopts thermochemical reaction method to prepare fly ash glass / ceramic composite coating on the surface of Q235 steel substrate, so as to improve the bonding strength and corrosion resistance of the coating and the substrate. and wear resistance.

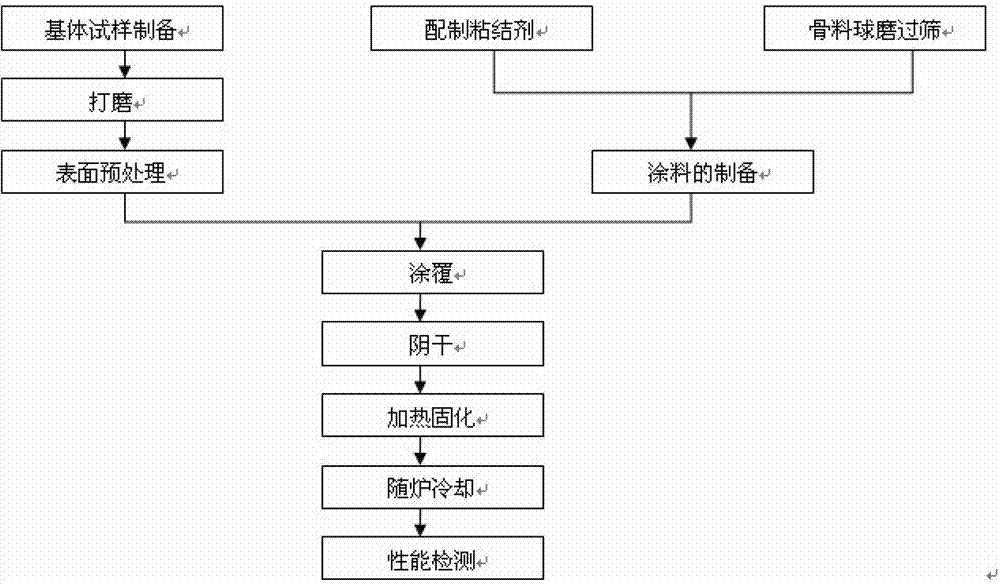

[0030] Described preparation method comprises the steps:

[0031] The first step, raw material preparation:

[0032] Select the coating aggregate fly ash, add Al to the fly ash at a mass percentage of 5%; then add SiO 2 、Al 2 o 3 , MgO and albite, so that SiO in the coating aggregate 2 :Al 2 o 3 :MgO:albite=67:22:5:5 (mass ratio); then add Al-B to it according to the mass percentage of 10% 2 o 3 -TiO 2 Exothermic system, where Al, B 2 o 3 and TiO 2 The atomic ratio ...

Embodiment

[0061] Below, according to the preparation method of fly ash glass / ceramic composite coating provided by the present invention, a kind of implementation process of preferred scheme is provided, and concrete preparation process and experimental effect are as follows:

[0062] The first step, raw material preparation:

[0063] Select the coating aggregate as ordinary fly ash powder, add Al to the fly ash at a mass percentage of 5%; then add SiO 2 、Al 2 o 3 , MgO and albite, so that SiO in the coating aggregate 2 :Al 2 o 3 :MgO:albite=67:22:5:5; then add Al-B according to the mass percentage of 10% 2 o 3 -TiO 2 Exothermic system, where Al, B 2 o 3 and TiO 2 The atomic ratio is 10:3:3. The molecular formula of albite is NaAlSi 3 o 8 .

[0064] The second step is the pretreatment of the coating aggregate.

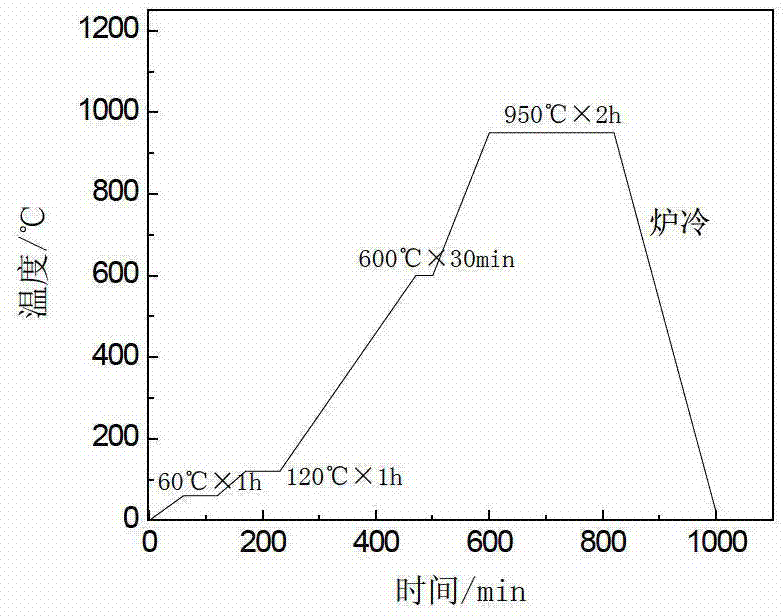

[0065] The fly ash was burned at 800 °C for 2 h for decarbonization, and the SiO 2 、Al 2 o 3 , MgO was burned at 900°C for 1h. Burnt fly ash, SiO 2 、Al 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com