Method for synthesizing m-trifluoromethyl acetophenone

A technology of trifluoromethyl acetophenone and trifluoromethyl aniline, which is applied in the field of synthesis of m-trifluoromethyl acetophenone, can solve the problems of high raw material prices, high risk, and difficulty in industrialization, and achieve impurity content Low, consistent quality and performance, methodologically safe and controllable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

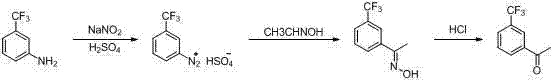

Method used

Image

Examples

Embodiment 1

[0028] A kind of synthetic method of m-trifluoromethyl acetophenone, take m-trifluoromethyl aniline as starting raw material, concrete steps comprise:

[0029] (1), diazotization reaction

[0030] 46 g m-trifluoromethylaniline was slowly added to a four-neck flask containing 280 g sulfuric acid solution (mass concentration 20%), then cooled to 0 °C and started to drop 30% NaNO 2 Aqueous solution 72 g, control temperature 0~5 ℃, heat preservation and stirring for 1 hour after dripping, obtain pale yellow diazonium salt clear liquid, heat preservation for later use.

[0031] (2), coupling reaction

[0032] Add 4.2 g of cuprous chloride, 10.2 g of acetic acid, 50.5 g of 50% acetaldehyde oxime aqueous solution and 100 mL of toluene into the four-neck flask, stir and cool. After cooling below 5°C, start to add the above-mentioned diazonium salt clear solution dropwise, and at the same time add 30% liquid caustic soda dropwise, control the pH at 4~4.5, and the temperature at 0~5°C...

Embodiment 2

[0037] (1), diazotization reaction

[0038] 46 g m-trifluoromethylaniline was slowly added to a four-neck flask containing 280 g sulfuric acid solution (mass concentration 25%), then cooled to 0 °C and started to drop 30% NaNO 2 Aqueous solution 71 g, control temperature 0~5 ℃, heat preservation and stirring for 1 hour after dripping, obtain light yellow diazonium salt clear liquid, heat preservation for later use.

[0039] (2), coupling reaction

[0040] Add 8.6 g of copper acetate, 5.2 g of acetic acid, 45.5 g of 50% acetaldehyde oxime aqueous solution and 100 mL of toluene into the four-neck flask, stir and cool. After cooling below 5°C, start to add the above-mentioned diazonium salt clear solution dropwise, and at the same time add 30% liquid caustic soda dropwise, control the pH at 4~4.5, and the temperature at 0~5°C. After the addition, the temperature was raised to 15°C and stirred, followed by GC analysis. After the reaction was completed, the mixture was separated ...

Embodiment 3

[0045] A kind of synthetic method of m-trifluoromethyl acetophenone, take m-trifluoromethyl aniline as starting raw material, concrete steps comprise:

[0046] (1), diazotization reaction

[0047] 46 g m-trifluoromethylaniline was slowly added to a four-neck flask containing 280 g sulfuric acid solution (mass concentration 25%), then cooled to 0 °C and started to drop 30% NaNO 2 Aqueous solution 72 g, control temperature 0~5 ℃, heat preservation and stirring for 1 hour after dripping, obtain pale yellow diazonium salt clear liquid, heat preservation for later use.

[0048] (2), coupling reaction

[0049] Add 3.9 g cupric chloride, 8.0 g acetic acid, 48.5 g 50% acetaldehyde oxime aqueous solution and 100 mL toluene into the four-neck flask, stir and cool. After cooling below 5°C, start to add the above-mentioned diazonium salt clear solution dropwise, and at the same time add 30% liquid caustic soda dropwise, control the pH at 4~4.5, and the temperature at 0~5°C. After the add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com