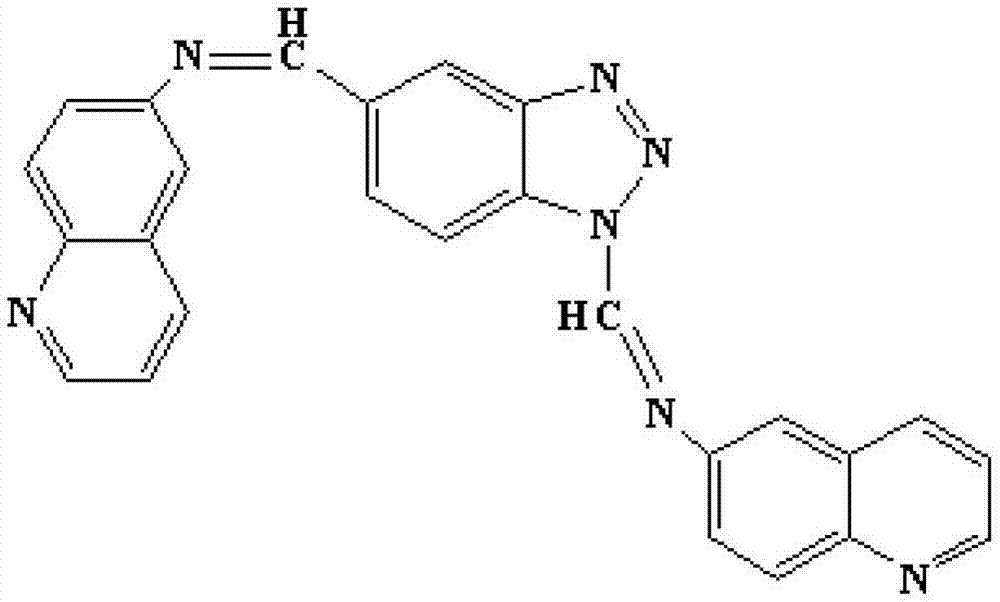

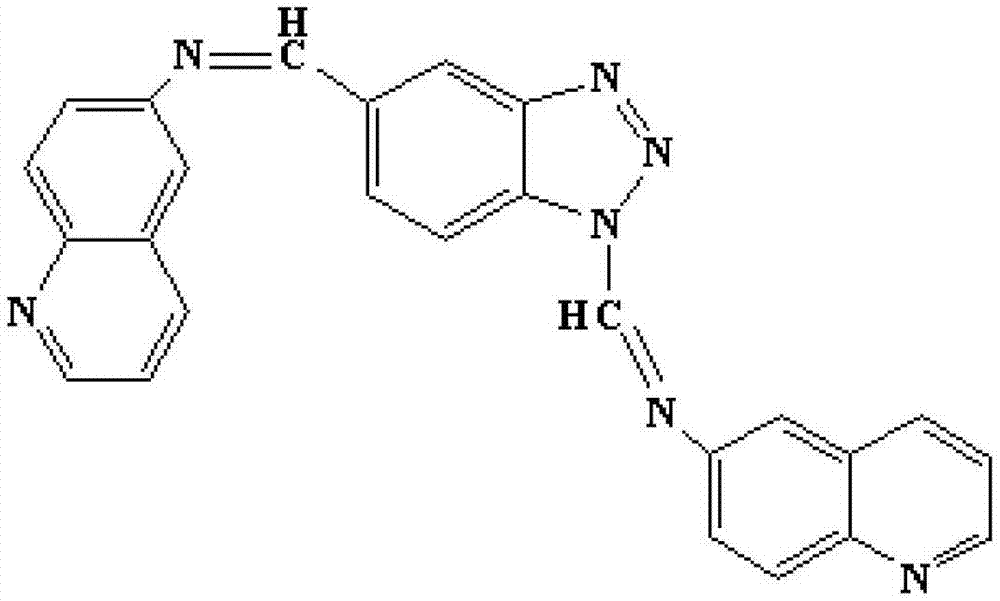

Benzotriazole Schiff base compound and preparation method thereof

A technology of benzotriazole Schiff bases and benzotriazoles is applied in the field of benzotriazole Schiff base compounds and preparation thereof, and can solve the problems such as rare benzotriazole Schiff base compounds, and achieves The synthesis method is simple, the yield is high, and the operation is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

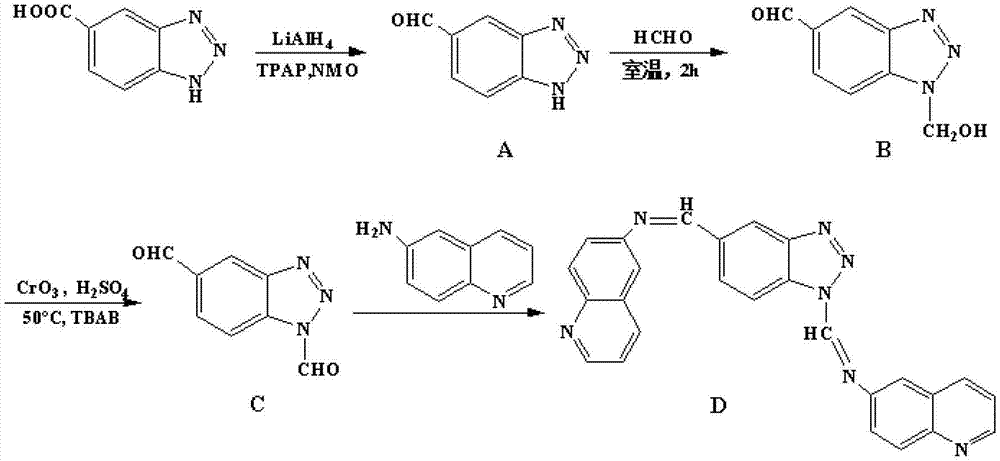

[0017] Embodiment 1: Preparation of benzotriazole Schiff base compound:

[0018] (1) Add 3.26g (20mmol) 5-carboxybenzotriazole and appropriate amount of LiAlH to a 100ml round bottom flask 4 and THF, control the temperature at about 20°C, add an appropriate amount of TPAP / NMO, CH 2 Cl 2 , THF, DMF at room temperature for 12 hours, and filtered under reduced pressure to obtain 2.62 g of white crude product 5-formylbenzotriazole A. (Yield: 89%)

[0019] (2) Add 2.62g (18mmol) A, 0.54g (18mmol) formaldehyde, 20ml acetic acid, 50ml water to a 100ml round-bottomed flask in turn, stir for 1h, place for 2h, and filter under reduced pressure to obtain the white crude product 1-hydroxymethyl Base-5-formylbenzotriazole B2.88g. (Yield: 90%)

[0020] (3) Add 2.83g (16mmol) B and 30ml CHCl to a 100ml double-necked bottle in sequence 3 and 1.5g of phase transfer catalyst tetrabutylammonium bromide TBAB, heated to dissolve. Slowly add the aqueous solution containing 1.60g (16mmol) chr...

Embodiment 2

[0027] Embodiment 2: Preparation of benzotriazole Schiff base compound:

[0028] (1) Add 3.26g (20mmol) 5-carboxybenzotriazole and appropriate amount of LiAlH to a 100ml round bottom flask 4 and THF, the temperature is controlled at around 40°C. After electromagnetic stirring for 12 hours, add an appropriate amount of TPAP / NMO, CH 2 Cl 2 , THF, DMF at room temperature for 8 hours, and filtered under reduced pressure to obtain 2.14 g of white crude product 5-formylbenzotriazole A. (Yield: 73%)

[0029] (2) Add 2.14g (14.5mmol) A, 0.45g (15mmol) formaldehyde, 20ml ethanol, 50ml water to a 100ml round-bottomed flask in sequence, stir for 1.5h, let stand for 2h, and filter under reduced pressure to obtain the white crude product 1- Hydroxymethyl-5-formylbenzotriazole B2.00g. (Yield: 78%)

[0030] (3) Add 1.95g (11mmol) B and 21ml CHCl to a 100ml double-necked bottle in sequence 3 and 1.1 g of phase transfer catalyst tetrabutylammonium bromide TBAB, heated to dissolve. Slow...

Embodiment 3

[0033] Embodiment 3: Preparation of benzotriazole Schiff base compound:

[0034](1) Add 3.26g (20mmol) 5-carboxybenzotriazole, appropriate amount of LiAlH4 and THF into a 100ml round bottom flask, control the temperature at about 20°C, add an appropriate amount of TPAP / NMO dropwise after electromagnetic stirring for 10 hours, CH2Cl2, THF, DMF were reacted at room temperature for 12 hours, and the white crude product 5-formylbenzotriazole A2.62g was obtained after suction filtration under reduced pressure. (Yield: 89%)

[0035] (2) Add 2.62g (18mmol) A, 0.54g (18mmol) formaldehyde, 20ml acetic acid, 50ml water to a 100ml round-bottomed flask in turn, stir for 1h, place for 2h, and filter under reduced pressure to obtain the white crude product 1-hydroxymethyl Base-5-formylbenzotriazole B2.88g. (Yield: 90%)

[0036] (3) Add 2.83g (16mmol) B and 30ml CHCl to a 100ml double-necked bottle in sequence 3 and 1.0 g of phase transfer catalyst tetrabutylammonium bromide TBAB, heated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com