Extraction and purification method for anthocyanin in purple sweet potato

A purification method and technology of purple sweet potato, applied in chemical instruments and methods, organic chemistry, azo dyes, etc., can solve problems such as the destruction of purple sweet potato anthocyanins, and achieve high-purity quality and stability assurance, production cost reduction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take 50g of purple sweet potato whole powder, mix it with 500mL of 3% citric acid aqueous solution to form purple sweet potato milk, take 50mL of slurry evenly, add 100U / mL of pectinase, cellulase, α-amylase respectively, and enzymatically hydrolyze at 50°C After 2 hours, the change of anthocyanin pigment content in purple sweet potato pulp was measured to determine the optimum enzyme amount.

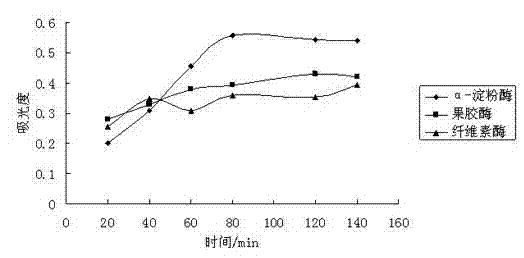

[0039] Experimental results such as figure 1 as shown, figure 1 The absorbance of the pigment extracted by α-amylase in the medium increases as the enzymatic hydrolysis time increases. Part of the pigment in the pigment solution is attached by macromolecular starch granules. When the enzymatic hydrolysis reaches 80 minutes, the pigment detachment reaches the maximum, and there is a downward trend after 80 minutes. The absorbance did not change much, so it was determined that the optimal enzymatic hydrolysis time of α-amylase was 80min. From 20min to 120min, the pectinase has no...

Embodiment 2

[0041] Take 50 mL of the uniform purple sweet potato slurry described in Example 1, add 200, 300, 400, 500, 600, 700 U / mL of α-amylase respectively, adjust the pH value to 5, and measure the purple sweet potato after enzymolysis at 50 ° C for 2 hours. Sweet potato anthocyanin pigment content, determine the optimum enzyme addition amount.

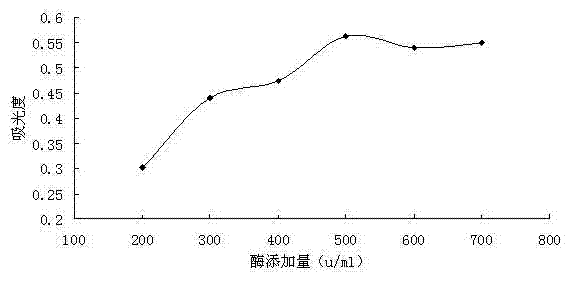

[0042] Experimental results such as figure 2 shown by figure 2 It can be seen that the pigment extraction effect is the best when the amount of α-amylase added is 500U / mL. Before 500U / mL, the enzyme dosage is insufficient, and some purple sweet potato anthocyanins have not been extracted. When 500U / mL, the pigment is extracted fully, and then continue to add For enzymes, the absorbance curve tends to be flat, and the absorbance does not change greatly, so 500U / mL is selected as the optimum amount of α-amylase added.

Embodiment 3

[0044]Take the above 50mL homogeneous slurry, add 150U / mL α-amylase respectively, adjust the pH value to 5, and measure the content of purple sweet potato anthocyanin pigment after enzymatic hydrolysis at 50, 60, 70, 80, 90°C for 2 hours respectively, and determine Optimum temperature for enzyme action.

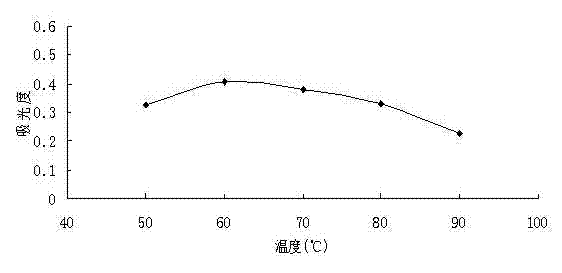

[0045] Experimental results such as image 3 shown by image 3 It can be seen that with the change of temperature, the absorbance of the enzymatic hydrolyzate increases first, then decreases gradually, and the absorbance reaches the maximum at 60°C. Before 60°C, the enzyme activity does not reach the maximum, but it has not been denatured, so the absorbance increases continuously. After 60°C, as the temperature rises, the spatial structure of all enzyme molecules is destroyed to varying degrees. The enzyme rapidly loses most of its biological activity, the enzyme denatures, the activity decreases, and the effect of the enzyme decreases, so the absorbance gradually decreases...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com