Adsorptive acid liquor retarding admixture and preparation method thereof

An admixture, adsorption-type technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of reduced foam acid stability, affected slow acidification effect, and increased acid filtration loss, etc. Good thermal stability, simple and feasible preparation method, and favorable effect of flowback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

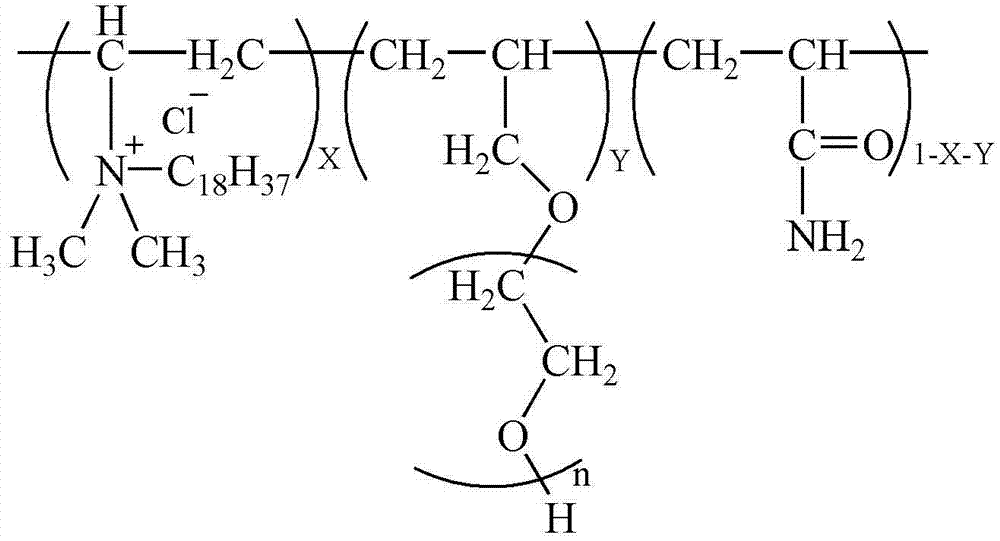

[0017] Example 1 A preparation method of an adsorption-type acid retarding admixture

[0018] First, add 0.747g or 0.002mol of octadecyldimethylallyl ammonium chloride BAZ and 1g or 0.001mol of allyl polyethylene glycol APEG and 2.84g of 0.04mol of acrylamide AM; then add 41.3g of deionized water to the above solution to form a solution with a monomer mass percentage concentration of 10%, stir and dissolve and add 0.018g of initiator azobisisobutylamidine hydrochloride Finally, after mixing the above solutions evenly, react at a temperature of 50°C for 6 hours to obtain a colloidal product, wash with absolute ethanol for 3 times until precipitation occurs, and dry in an oven at a temperature of 50°C for 24 hours to obtain this product Acid retarding admixture.

Embodiment 2

[0019] Example 2 A preparation method of an adsorption-type acid retarding admixture

[0020] First add 0.672g (0.0018mol) of octadecyldimethylallyl ammonium chloride BAZ and 1g (0.001mol) of allyl polyethylene glycol APEG and 2.84g (0.001mol) to a silk-top reagent bottle with a volume of 100mL. 0.04mol of acrylamide AM; then add 40.6g of deionized water to the above solution to form a solution with a monomer mass percentage concentration of 10%, stir and dissolve and add 0.018g of initiator azobisisobutylamidine hydrochloride Finally, after mixing the above solutions evenly, react at a temperature of 50°C for 6 hours to obtain a colloidal product, wash with absolute ethanol for 3 times until precipitation occurs, and dry in an oven at a temperature of 50°C for 24 hours to obtain this product Acid retarding admixture.

Embodiment 3

[0021] Example 3 A preparation method of an adsorption-type acid retarding admixture

[0022] First add 0.672g or 0.0018mol of octadecyldimethylallyl ammonium chloride BAZ and 0.8g or 0.0008mol of allyl polyethylene glycol APEG and 2.84g That is, 0.04mol of acrylamide AM; then add 38g of deionized water to the above solution to form a solution with a monomer mass percentage concentration of 10%, stir and dissolve and add 0.017g of initiator azobisisobutylamidine hydrochloride Finally, after mixing the above solutions evenly, react at a temperature of 50°C for 6 hours to obtain a colloidal product, wash with absolute ethanol for 3 times until precipitation occurs, and dry in an oven at a temperature of 50°C for 24 hours to obtain this product Acid retarding admixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com