Method for concentrating platinum group metals from alumina-based waste catalyst

A technology of platinum group metals and catalysts, which is applied in the field of enriching platinum group metals, can solve the problems of high energy consumption for carrier fusion, low dissolution efficiency, and high production cost, and achieve low equipment corrosion, good enrichment effect, and small equipment corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

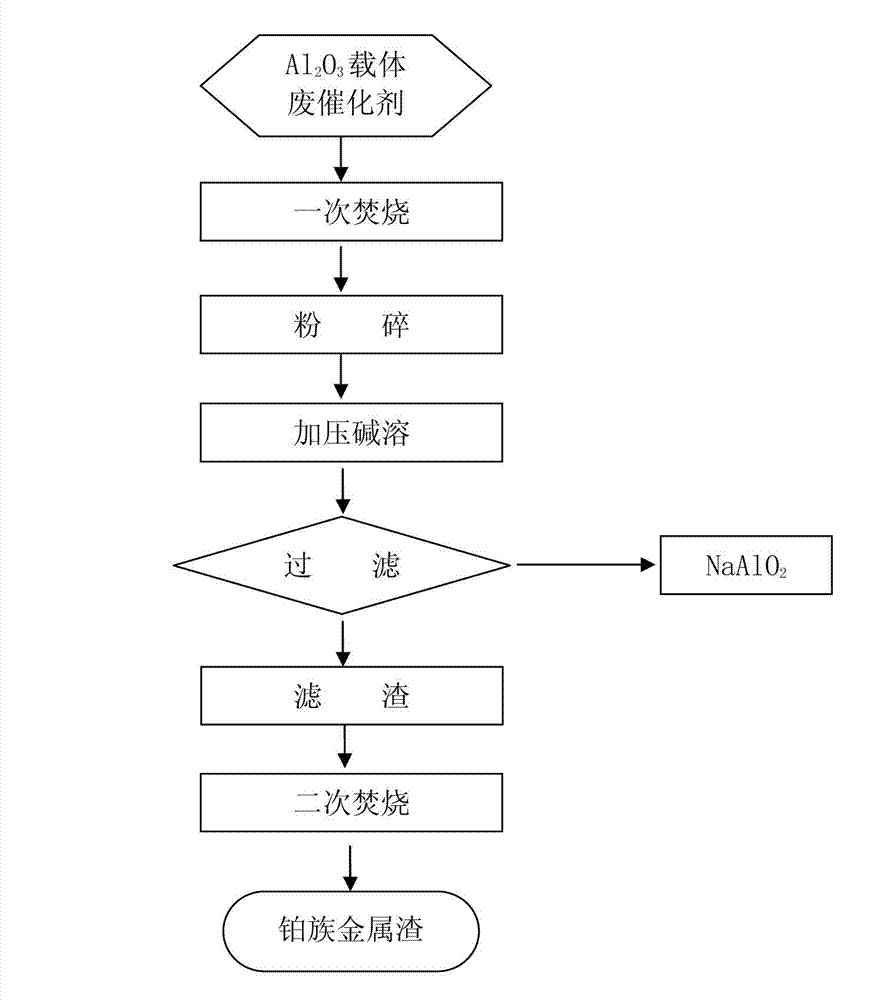

[0030] like figure 1 As shown, a method for enriching platinum group metals from alumina-based spent catalysts comprises the following steps:

[0031] A. Primary incineration: incinerate the platinum-containing alumina-based waste catalyst at 600°C until the carbon content of the catalyst is less than 1%;

[0032] B, pulverization: the spent catalyst ball milling after step A gained charcoal is to 70 orders;

[0033] C. Pressurized alkali dissolution: 500g of the pulverized alumina-based waste catalyst obtained in step B, the platinum content is 2059g / T, 1000g of 28% NaOH solution is added, and 2.5g of hydrazine hydrate is added, and put into a stainless steel autoclave In the process, the temperature was raised to 140°C within 2 hours, the pressure was 0.3MPa, and after 2.5 hours of constant temperature and pressure, the temperature was raised to 190°C in 1.5 hours, the pressure was 1.2MPa, and the constant temperature was 2 hours;

[0034] D. Filtration: Filter the soluti...

Embodiment 2

[0037] A method for enriching platinum group metals from alumina-based spent catalysts, comprising the steps of:

[0038] A. Primary incineration: Incinerate the platinum-containing alumina-based waste catalyst at 620°C until the carbon content of the catalyst is less than 1%;

[0039] B, pulverization: the spent catalyst ball milling after step A gained charcoal is to 75 orders;

[0040] C, pressurized alkali dissolution: 500g of the crushed alumina-based waste catalyst obtained in step B, the platinum content is 2172g / T, add 1000g of 30% NaOH solution, add 3g of sodium formate, put it into a stainless steel autoclave, and Heating to 135°C within 2 hours, pressure 0.3MPa, constant temperature and pressure for 2.5 hours, heating to 190°C in 1 hour, pressure 1.3MPa, constant temperature for 2.5 hours;

[0041] D. Filtration: Filter the solution obtained in step C at 130°C, wash 10.85g of the filter residue with 65.1g of 80°C hot water each time, wash 3 to 4 times, check with h...

Embodiment 3

[0044] A method for enriching platinum group metals from alumina-based spent catalysts, comprising the steps of:

[0045] A. Primary incineration: Incinerate the palladium-containing alumina-based waste catalyst at 650°C until the carbon content of the catalyst is less than 1%;

[0046] B, pulverization: the waste catalyst ball milling to 80 orders after the charcoal burning of gained in step A;

[0047] C, pressurized alkali dissolution: 500g of alumina-based waste catalysts pulverized by step B gained, palladium content is 2979g / T, add 30% NaOH solution 1250g, add 4g sodium formate again, put into stainless steel autoclave, in Heating to 130°C within 2 hours, pressure 0.4MPa, constant temperature and pressure for 2 hours, heating to 195°C in 1 hour, pressure 1.4MPa, constant temperature for 3 hours;

[0048] D. Filtration: Filter the solution obtained in step C at 135°C, wash 10.9g of filter residue with 87.2g of 85°C hot water each time, wash 3 to 4 times, check with hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com