Rapid screening method of high-yielding coenzyme Q10 strain

A technology of high-yielding strains and coenzymes, applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problems of high measurement results, large errors, and affecting screening efficiency, so as to improve efficiency, shorten the breeding cycle, and ensure reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Determination of the most suitable amount of reducing agent

[0022] Taking the reducing agent as sodium borohydride as an example:

[0023] The preparation concentration is 80mg / L oxidized coenzyme Q 10 For the standard product, accurately draw 3mL into the quartz cuvette, then add 2μL, 6μL, 12μL, 16μL, 20μL, 32μL, 40μL, 50μL of sodium borohydride solution with a concentration of 9mg / mL, shake evenly, and use absolute ethanol as For comparison, measure the absorbance at 275 nm after the bubbles disappear, and record the final stable value. The results are shown in Table 1.

[0024] Table 1 The most suitable amount of reducing agent

[0025]

[0026] It can be seen from Table 1 that after adding the reducing agent, the absorbance value at 275nm wavelength will gradually decrease with the increase of the dosage of sodium borohydride solution. It was determined that when 20 μL of sodium borohydride was added, coenzyme Q 10 has been fully restored.

[0...

Embodiment 2

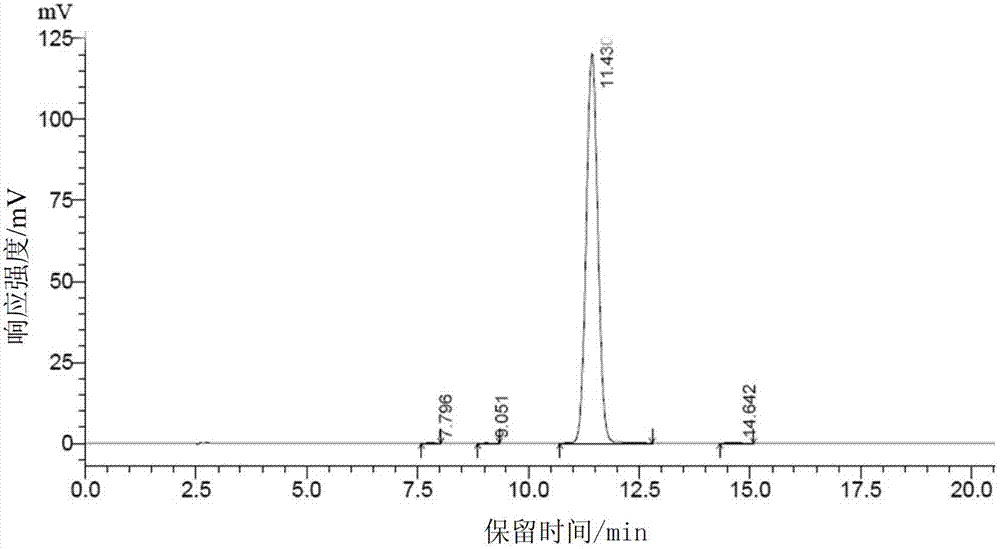

[0032] Example 2: Preparation of Coenzyme Q10 Concentration-Absorbance Difference Standard Curve

[0033] Determination of oxidized coenzyme Q at concentrations of 8mg / L, 16mg / L, 32mg / L, 48mg / L, 64mg / L, and 80mg / L 10 Standards and Reduced Coenzyme Q 10 △A (oxidized OD275nm-reduced OD275nm) can be obtained from the absorbance value of the standard at 275nm, and then for different concentrations of coenzyme Q 10 Standard products do linear regression, that is, coenzyme Q 10 Concentration-absorbance difference standard curve, such as Figure 4 shown.

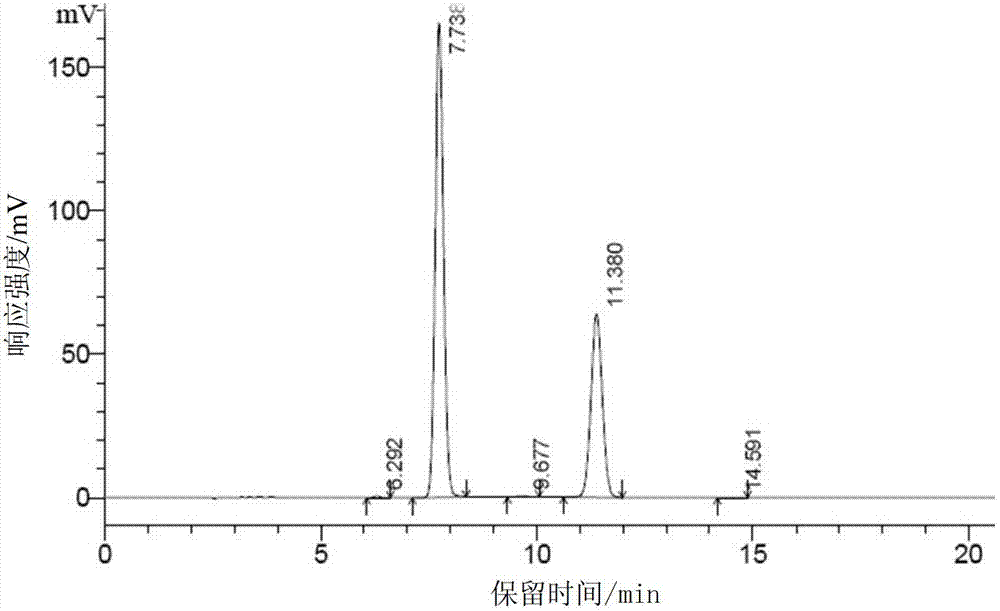

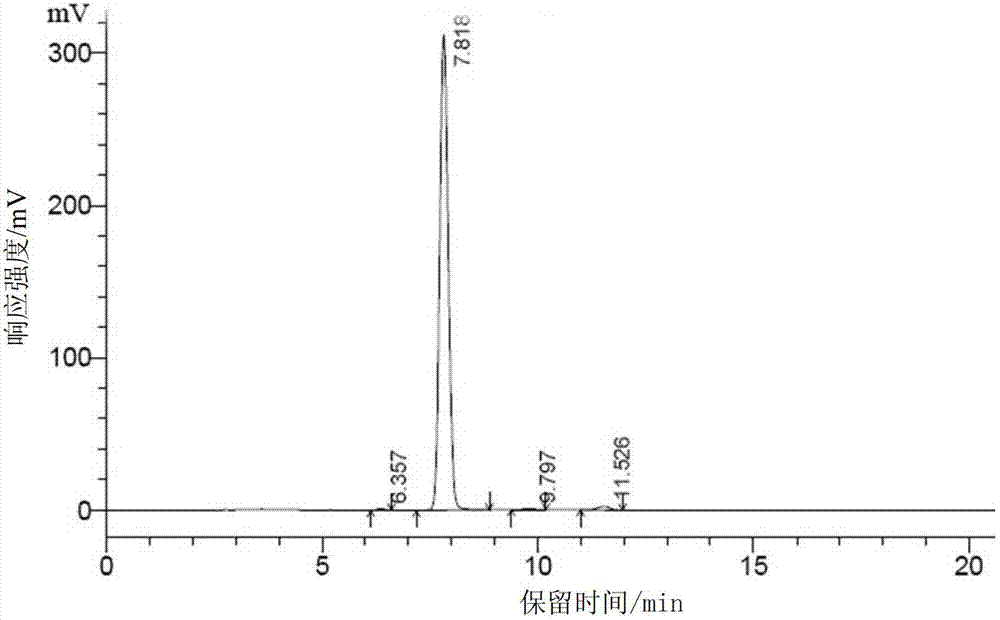

Embodiment 3

[0035] 1. Cell mutagenesis fermentation

[0036] The starting strain Rhodobacter sphaeroides (Rhodobacter sphaeroides) JDW-610 species conservation slant was separated by drawing a line, and then the mature single colony was inserted into a fresh slant, cultured at 32°C for 2 days, and then washed with 5 mL of sterile water. Transfer the suspension into a conical flask containing 25mL pH6.0 PBS buffer solution and several glass beads, mix well, add NTG to make the NTG concentration in the final bacterial solution 0.2mg / mL, and treat the bacterial solution in a water bath at 32°C for 15min. The reaction was terminated by diluting with pH 6.0 PBS buffer solution, and the bacterium solution after mutagenesis was applied to a plate medium containing 0.002 g / L sodium azide, and cultured at 32° C. for 5 days.

[0037] The Rhodobacter sphaeroides JDW-610 was deposited in the General Microbiology Center of the China Committee for the Collection of Microorganisms on December 21, 2010, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com