Variable optical attenuator based on liquid crystal cladding polymer optical waveguide

A technology of optical waveguide and polymer, which is applied in the direction of light guide, optics, instruments, etc., can solve the problems of inability to realize integration, large volume, etc., and achieve the effect of increasing dynamic tunable range, large tuning efficiency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

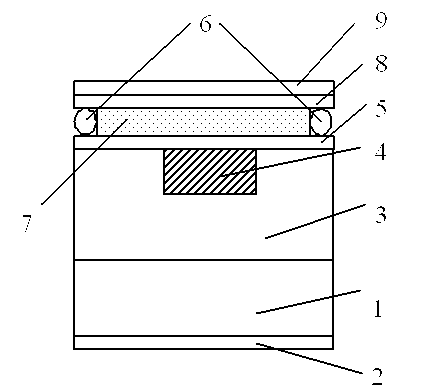

[0022] Such as figure 1 As shown, a tunable optical attenuator based on a liquid crystal cladding polymer optical waveguide adopts a vertical electrode structure, which specifically includes a silicon substrate 1, a lower electrode 2, a silicon dioxide lower cladding layer 3, and a polymer optical waveguide Core layer 4 , liquid crystal lower alignment layer 5 , liquid crystal spacer layer 6 , liquid crystal layer 7 , liquid crystal upper alignment layer 8 , and upper electrode 9 . The silicon substrate 1 is a heavily doped silicon material with a conductivity of 2×10 -2 More than Ω·cm; directly above the silicon substrate 1, a 7-10 μm thick silicon dioxide lower cladding layer 3 is grown by chemical vapor deposition, and its refractive index is 1.45; directly below the silicon substrate 1, a layer of metal nickel is electroplated by electroless plating , this layer of me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com