Controllable preparation method of micron-order Fe3O4

A micron-scale, solution technology, applied in ferrous oxides, iron oxides/iron hydroxides, etc., can solve the problems of uncontrollable nucleation and growth, narrow particle size distribution of micron-sized particles, and high phase purity. The effects of controllable nucleation and growth processes, high particle crystallinity, and high sample phase purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

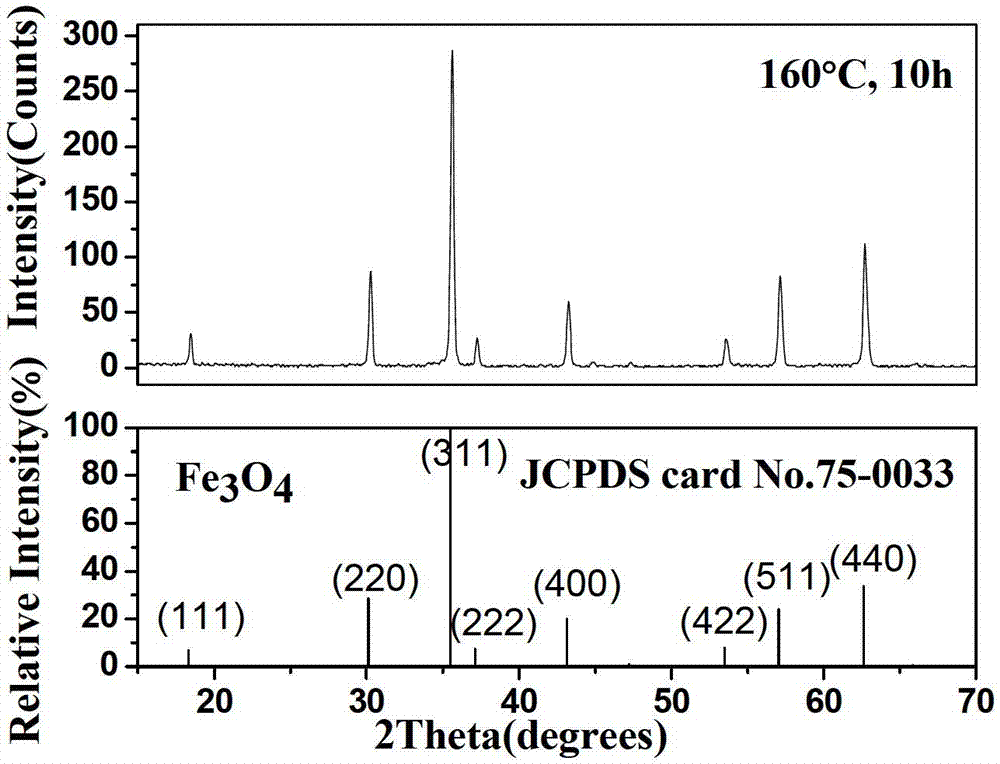

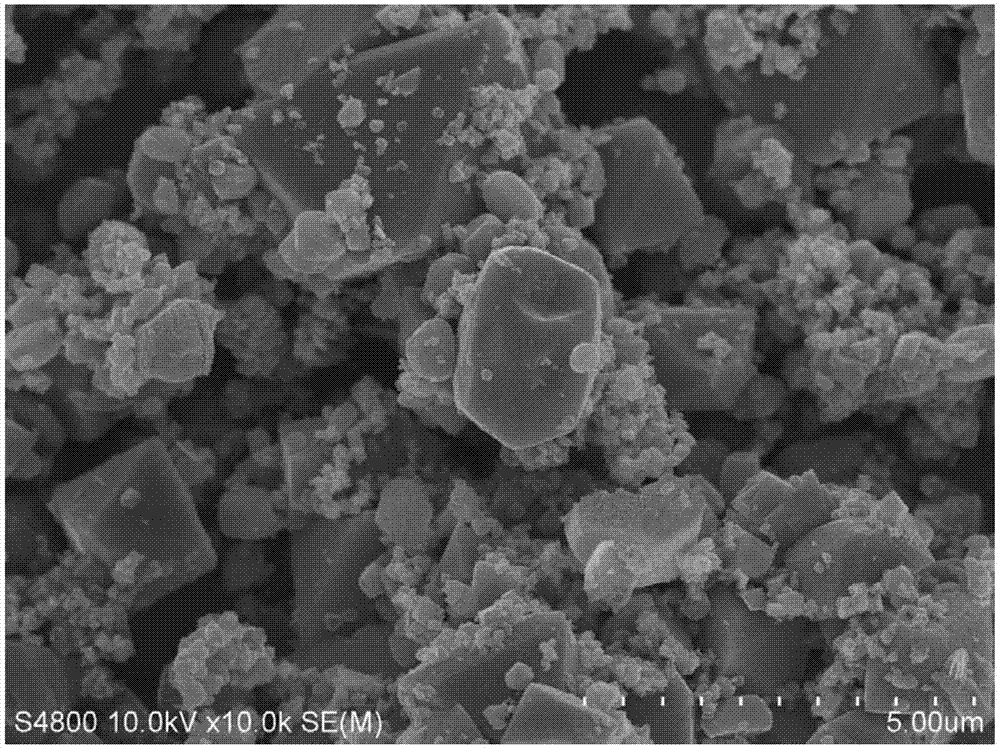

Embodiment 1

[0027] 1) FeSO 4 ·7H 2 O and NaOH are dissolved in distilled water respectively, and form FeSO with a concentration of 2.0mol / L after dissolution 4 Solution and concentration are the NaOH solution of 16.80mol / L;

[0028] 2) FeSO configured in step 1 4 The solution is dissolved in the NaOH solution configured in step 1, and the FeSO 4 The volume ratio of the solution to the NaOH solution is 2:5, stir to fully dissolve it;

[0029] 3) The mixed solution obtained in step 2 was assisted with low-frequency ultrasonic treatment, the ultrasonic power was 40W, and the ultrasonic time was 8min, until the mixed solution was light green;

[0030] 4) Transfer the solution obtained in step 3 into a Teflon hydrothermal kettle with a volume of 60%, and keep it warm for 10 hours at a temperature of 160°C;

[0031] 5) Add 200ml of distilled water to the precipitate obtained in step 4 to rinse, and perform centrifugation. The centrifuge speed is 12000r / min, and the centrifugation time is 5...

Embodiment 2

[0035] 1) FeSO 4 ·7H 2 O and NaOH are dissolved in distilled water respectively, and form FeSO with a concentration of 3.50mol / L after dissolution. 4 solution and a NaOH solution with a concentration of 11.00mol / L;

[0036] 2) FeSO configured in step 1 4 The solution is dissolved in the NaOH solution configured in step 1, and the FeSO 4 The volume ratio of the solution to the NaOH solution is 2:5, stir to fully dissolve it;

[0037] 3) The mixed solution obtained in step 2 was assisted with low-frequency ultrasonic treatment, the ultrasonic power was 70W, and the ultrasonic time was 12min, until the mixed solution was light green;

[0038] 4) Transfer the solution obtained in step 3 into a Teflon hydrothermal kettle with a volume of 80%, and keep it warm for 15 hours at a temperature of 200°C;

[0039] 5) Add 200ml of distilled water to the precipitate obtained in step 4 to rinse, and perform centrifugation. The centrifuge speed is 12000r / min, and the centrifugation time ...

Embodiment 3

[0043] 1) FeSO 4 ·7H 2 O and NaOH are dissolved in distilled water respectively, and form FeSO with a concentration of 5.0mol / L after dissolution. 4 solution and a NaOH solution with a concentration of 20.00mol / L;

[0044] 2) FeSO configured in step 1 4 The solution is dissolved in the NaOH solution configured in step 1, and the FeSO 4The volume ratio of the solution to the NaOH solution is 2:5, stir to fully dissolve it;

[0045] 3) The mixed solution obtained in step 2 was assisted with low-frequency ultrasonic treatment, the ultrasonic power was 70W, and the ultrasonic time was 10min, until the mixed solution was light green;

[0046] 4) Transfer the solution obtained in step 3 into a Teflon hydrothermal kettle with a volume of 90% at a filling ratio of 90%, and keep it warm for 10 hours at a temperature of 280°C;

[0047] 5) Add 200ml of distilled water to the precipitate obtained in step 4 to rinse, and perform centrifugation. The centrifuge speed is 12000r / min, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com