High-content fluorine-containing polymer processing master batch and preparation method thereof

A polymer and high-content technology, which is applied in the field of high-content fluorine-containing polymer processing masterbatch and its preparation, can solve the problems of increasing the complexity of the preparation process, the preparation process is complicated, and the application and promotion are limited, and the addition is small and the process is Simple process and wide versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

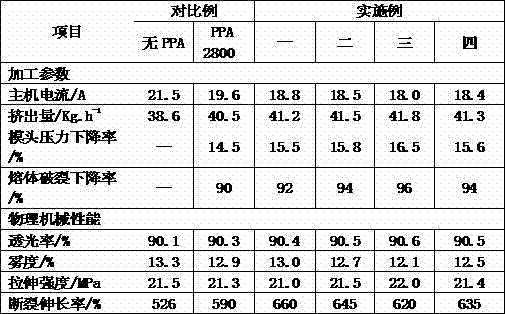

Embodiment 1

[0038] Put the commercially available 70% fluorine-containing processing aid PPA 2800, whose composition is a copolymer of tetrafluoroethylene and hexafluoropropylene, with a weight average molecular weight of 500,000 to 5 million, and 30% pentaerythritol distearate into a high-speed mixer Stir at high speed to 70-80°C, stir for about 15 minutes, when there is no dust, add the mixed bonding material to the double-roll cold press molding machine, extrude into cylindrical masterbatch at room temperature, vibrate and sieve, and make High content of fluoropolymer processing masterbatch.

Embodiment 2

[0040]Put 80% fluorine-containing processing aid PPA 2800 and 20% pentaerythritol distearate into a high-speed mixer and stir at a high speed to 70-80°C for about 15 minutes. When there is no dust, put the mixed adhesive The material is fed into a twin-roller cold press molding machine, extruded into a cylindrical masterbatch at room temperature, vibrating and sieved to obtain a high-content fluorine-containing polymer processing masterbatch.

Embodiment 3

[0042] Put 90% fluorine-containing processing aid PPA 2800 and 10% pentaerythritol distearate into a high-speed mixer and stir at a high speed to 70-80°C for about 15 minutes. When there is no dust, put the mixed adhesive The material is fed into a twin-roller cold press molding machine, extruded into a cylindrical masterbatch at room temperature, vibrating and sieved to obtain a high-content fluorine-containing polymer processing masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com