Heat radiation material, heat radiation structure, and preparation method thereof

A technology of heat-dissipating materials and heat-dissipating structures, applied in fibrous fillers, polyurea/polyurethane coatings, cooling/ventilation/heating transformation, etc. problems, to achieve the effect of improving lifespan, improving compatibility and system dispersion stability, and effectively dissipating heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

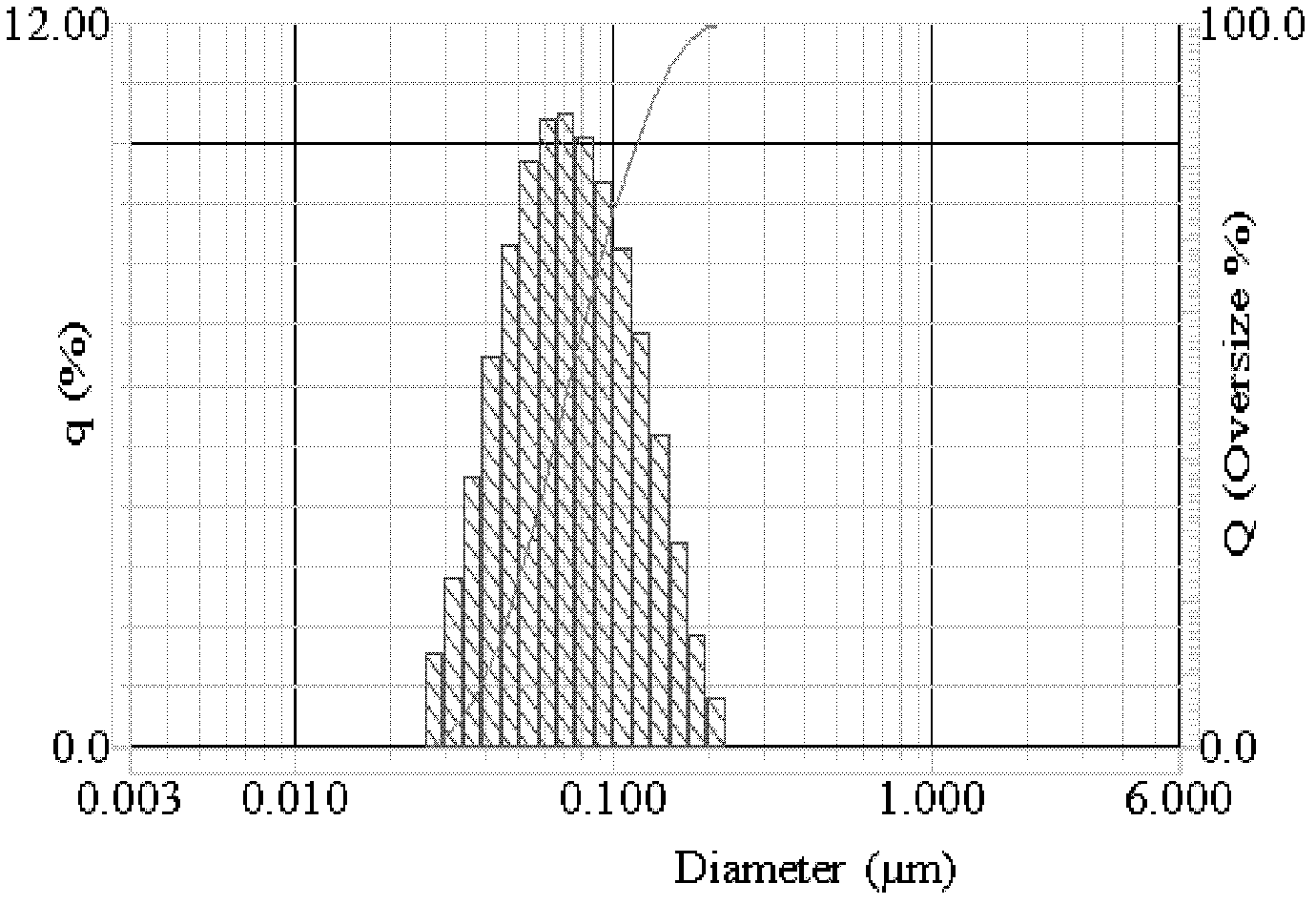

[0037] In this embodiment, the water-based slurry of inorganic heat-dissipating nanomaterials uses polyvinyl alcohol as a dual-functional macromolecular modifier, and the ester bonds and hydrogen bonds formed on the surface of the nanomaterials of carbon nanotubes are used to obtain a stable and dispersed water-based slurry The solid content of this water-based slurry is 25%, and the particle size of the heat-dissipating nano-carbon is all at 50-100nm, and its components and parts by weight are as follows:

[0038] Heat dissipation nanomaterials: carbon nanotubes (CN) 15

[0039] Deionized water 75

[0040] Polyvinyl alcohol (M W =2000) 10

[0041] Sample 1:

[0042] First take by weighing 15g carbon nanotubes and put into the water of 75g, adjust pH to be 9, under agitation condition, with the speed of 2ml / min, the polyvinyl alcohol of 10g (W W = 2000) dropwise into the above aqueous solution, stirring at room temperature or ultrasonic wave for 10 minutes to 12 hours unti...

Embodiment 2

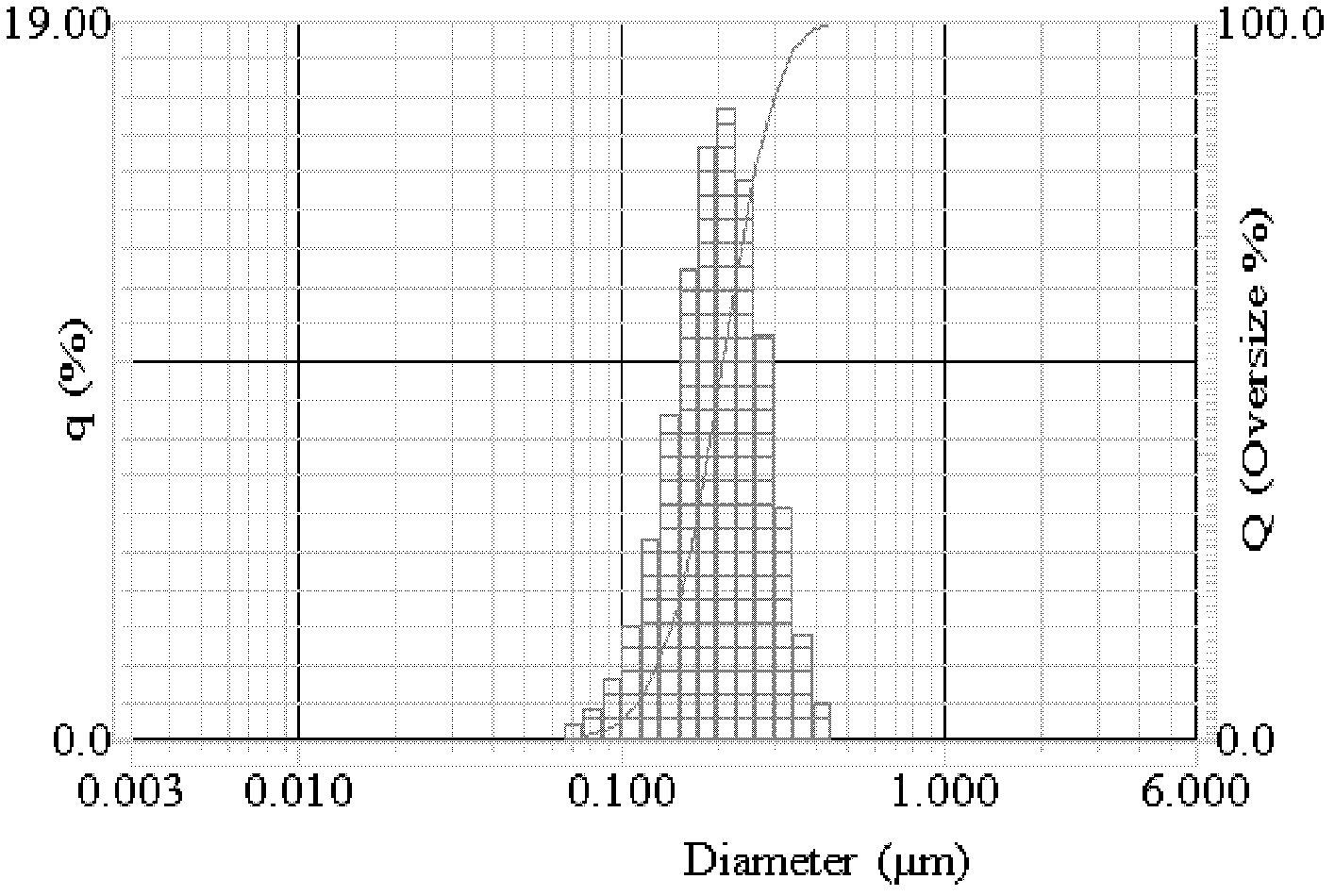

[0047] The water-based slurry of inorganic heat-dissipating nanomaterials uses polyether-modified silicone as a bifunctional macromolecule modifier, and ester bonds and hydrogen bonds formed on the surface of nanomaterials of carbon nanotubes are used to obtain a stable and dispersed water-based slurry; The solid content of the water-based slurry is 25%, and the particle size of the heat-dissipating nano-carbon is 50-100nm, and its components and parts by weight are as follows:

[0048] Heat dissipation nanomaterials: carbon nanotubes (CN) 15

[0049] Deionized water 75

[0050] Polyether modified organosilane (M W =500) 10

[0051] The specific preparation steps are the same as the preparation method of sample 1 in Example 1.

Embodiment 3

[0053] In the water-based slurry of inorganic heat-dissipating nanomaterials, polyethylene glycol is used as a bifunctional macromolecular modifier, and ester bonds and hydrogen bonds formed on the surface of nanomaterials of carbon nanotubes are used to obtain a stably dispersed water-based slurry; the water-based slurry The solid content of the material is 25%, and the particle size of the heat-dissipating nano-carbon is 50-100nm, and its components and parts by weight are as follows:

[0054] Heat dissipation nanomaterials: carbon nanotubes (CN) 15

[0055] Deionized water 75

[0056] polyethylene glycol (M W =200) 10

[0057] The specific preparation steps are the same as the preparation method of sample 1 in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com