Application of organosilicon-modified high-molecular compound as seed coating film-forming agent

A high molecular compound and organosilicon technology, which is applied in the direction of seed coating/seed dressing, application, animal repellent, etc., can solve the problems of complex processing technology, poor stability, poor water permeability, etc., and achieve strong compatibility and weather resistance Excellent performance and improved air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

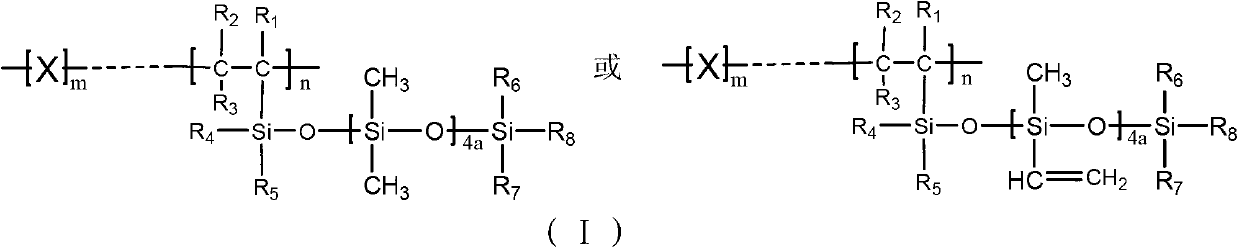

[0066] In a stirring four-neck flask, add 0.5 parts of vinyltrimethoxysilane, 5 parts of octamethylcyclotetrasiloxane, 1.5 parts of 99% acrylamide, 1 part of acrylic acid, 0.1 parts of ammonium persulfate, 5 parts of butyl acrylate, 1 part of acrylonitrile, 0.2 part of sodium dodecylbenzenesulfonate, 0.1 part of N, N, N', N'-tetramethylethylenediamine, 750 parts of deionized water, After raw materials, stir rapidly for 30 minutes, then heat to 75°C--80°C, keep warm for 3 hours, stop heating, cool to room temperature, adjust pH value with ammonia water, stir evenly and discharge. Obtain viscous transparent liquid, its pH value is 6.8, the viscosity at room temperature is 1900mPaS, the viscosity average molecular weight is 750,000, m≈2000, n≈1060, and the structural formula is

[0067]

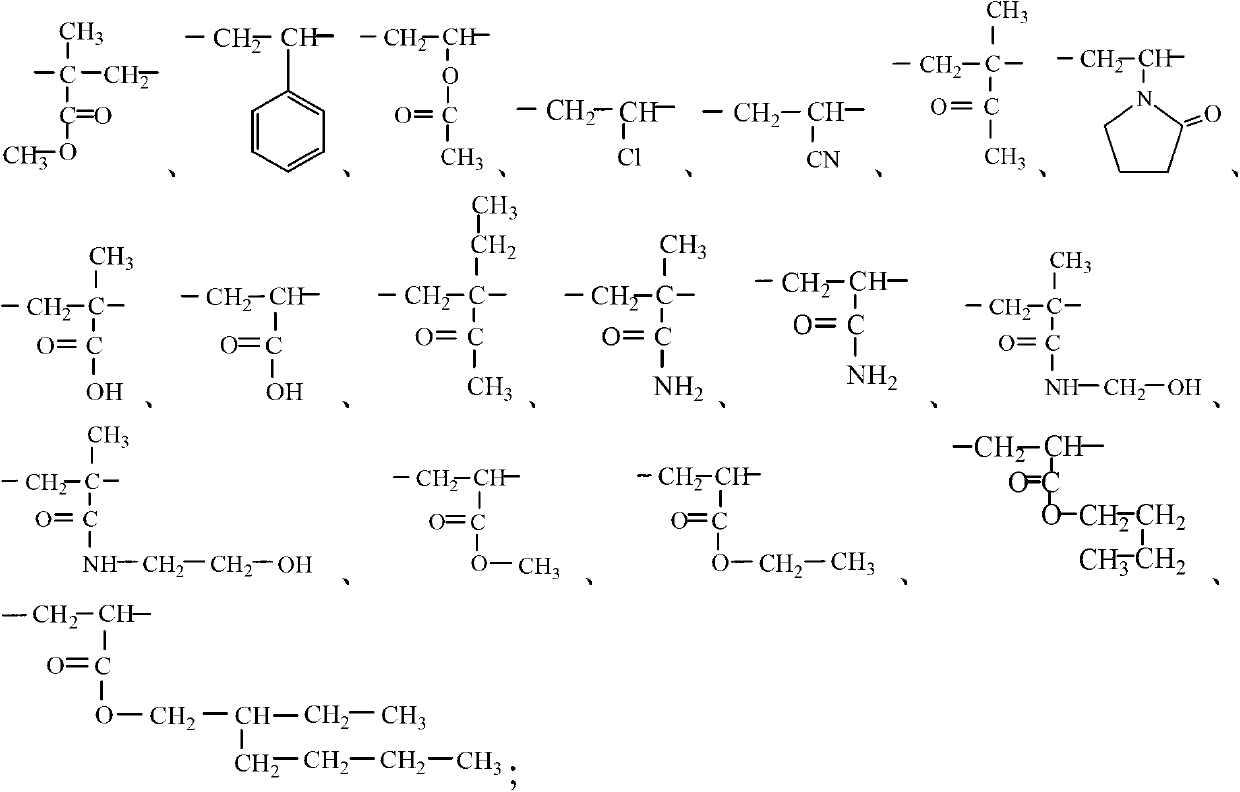

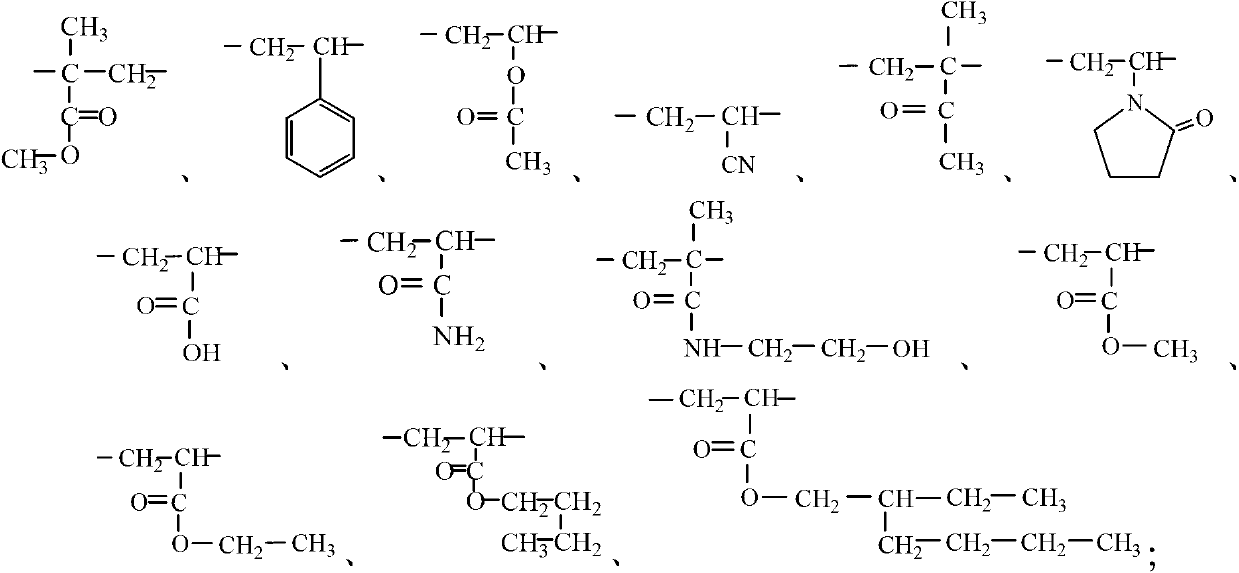

[0068] X is the group shown below:

[0069]

[0070] R 1 , R 2 , R 3 is hydrogen;

[0071] R 4 , R 5 , R 6 , R 7 is methoxy;

[0072] R 8 for vinyl.

Embodiment 2

[0074] In a stirring four-neck flask, add 0.5 parts of vinyltrimethoxysilane, 5 parts of octamethylcyclotetrasiloxane, 1.3 parts of 99% acrylamide, 1 part of acrylic acid, 0.2 parts of ammonium persulfate, 5 parts of butyl acrylate, 1 part of methyl methacrylate, 0.1 part of sodium dodecylbenzenesulfonate, 0.1 part of N, N, N', N'-tetramethylethylenediamine, 125 parts of deionized water, After adding all raw materials, stir rapidly for 30 minutes, then heat to 75°C--80°C, keep warm for 3 hours, stop heating, cool to room temperature, adjust the pH value with ammonia water, stir and discharge evenly. Obtain viscous transparent liquid, its pH value is 6.8, the viscosity at room temperature is 1750mPaS, the viscosity average molecular weight is 625,000, m≈1810, n≈1030, and the structural formula is:

[0075]

[0076] X is the group shown below:

[0077]

[0078] R 1 , R 2 , R 3 is hydrogen;

[0079] R 4 , R 5 , R 6 , R 7 is methoxy;

[0080] R 8 for vinyl.

Embodiment 3

[0082]In a four-neck flask with stirring, add 0.5 parts of vinyltriethoxysilane, 5 parts of tetramethyltetravinylcyclotetrasiloxane, and then add 1 part of 99% acrylamide, 1 part of acrylic acid, persulfuric acid 0.1 part of ammonium, 5 parts of N-vinylpyrrolidone, 1 part of acrylonitrile, 0.2 part of sodium dodecylbenzenesulfonate, 0.1 g of N, N, N', N'-tetramethylethylenediamine, deionized water 75 parts, after adding all raw materials, stir rapidly for 30 minutes, then heat to 75°C-80°C, keep warm for 3 hours, stop heating, cool to room temperature, adjust pH value with ammonia water, stir evenly and discharge. A viscous transparent liquid was obtained with a pH value of 6.8, a viscosity of 2200mPaS at room temperature, a viscosity-average molecular weight of 800,000, m≈2100, n≈1050, and the structural formula was:

[0083]

[0084] X is the group shown below:

[0085]

[0086] R 1 , R 2 , R 3 is hydrogen;

[0087] R 4 , R 5 , R 6 , R 7 is ethoxy;

[0088] R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com