Preparation method of magnetic microspheres

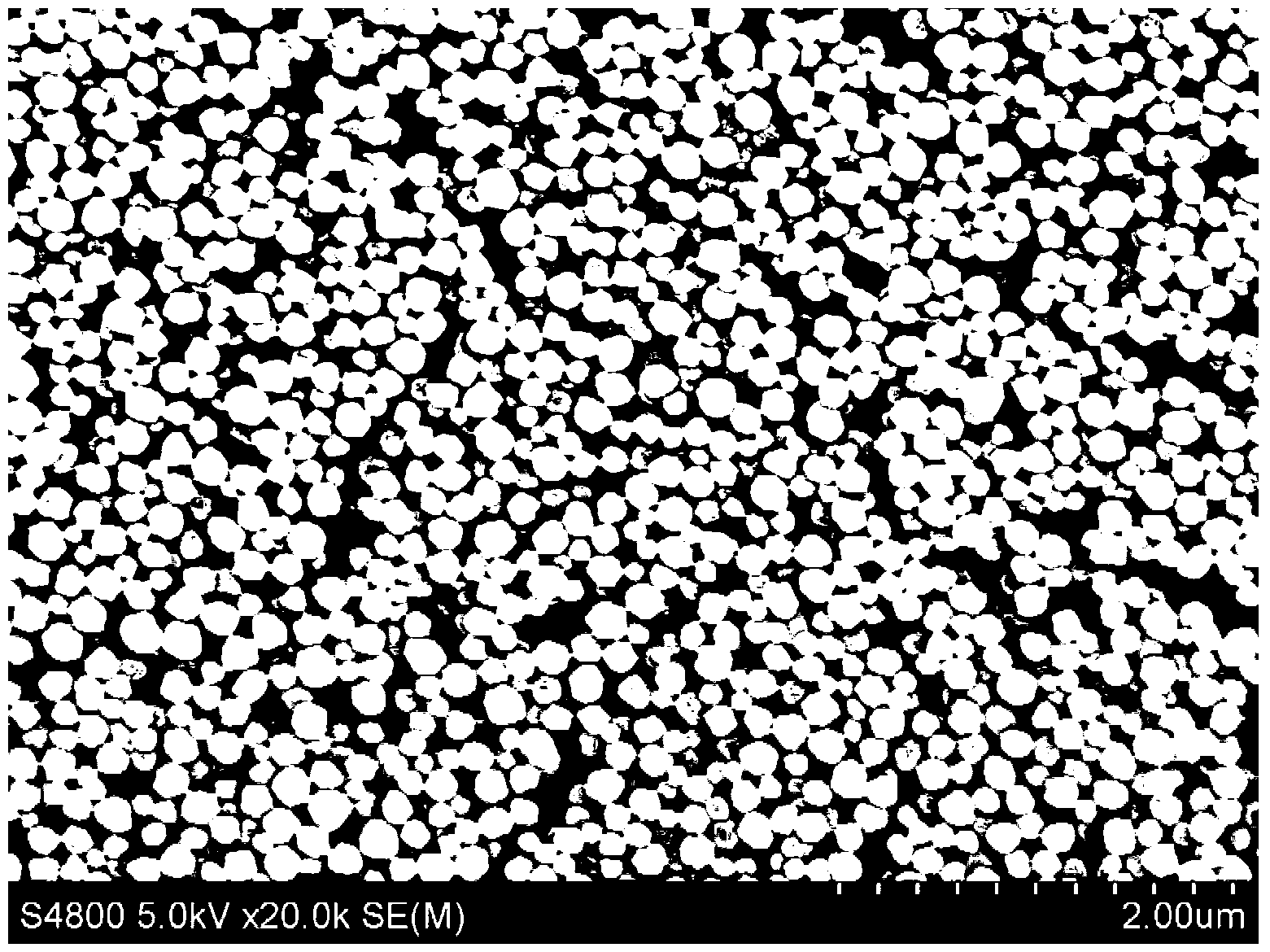

A microsphere and magnetic technology, applied in the field of preparation of magnetic microspheres, can solve the problems of uneven distribution of magnetite and large particle size distribution of magnetic microspheres, and achieve excellent magnetic responsiveness, uniform particle size, and excellent redispersion. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: the preparation method of magnetic microspheres in this embodiment is realized according to the following steps:

[0020] 1. Add 70-80mL of ethylene glycol into a 100mL round-bottomed flask, and add 2-3g of FeCl under magnetic stirring. 3 ·6H 2 O, to form a homogeneous solution, then add 6-7g of sodium acetate and 1-2g of polyethylene glycol, stir vigorously for 30 minutes, seal it in a stainless steel autoclave with a polytetrafluoroethylene liner, heat it to 200°C and keep it at a constant temperature for 8 ~10h, then cooled to room temperature, the obtained product was washed 2~4 times with absolute ethanol, and then dried at 60°C for 6h to obtain Fe 3 o 4 Nano magnetic particles;

[0021] Two, the obtained Fe in step 1 3 o 4 Nano-magnetic particles were added to a 200mL three-necked flask containing 75mL deionized water, stirred ultrasonically and nitrogen gas was introduced for 30 minutes to form a nitrogen atmosphere, then 1mL oleic a...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, 75 mL of ethylene glycol is added to a 100 mL round bottom flask, and 2.36 g of FeCl is added under magnetic stirring. 3 ·6H 2 O, form a homogeneous solution, then add the sodium acetate of 6.3g, the polyethylene glycol of 1.75g. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that 1.4 g of polyvinylpyrrolidone is added during stirring in Step 3. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com