Cadmium-doped bismuth molybdate visible-light-induced photocatalyst and preparation method and application of cadmium-doped bismuth molybdate visible-light-induced photocatalyst

A catalyst, visible light technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. problems such as low catalytic performance, to achieve good activity stability, high practical value and application prospects, and the effect of convenient separation and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

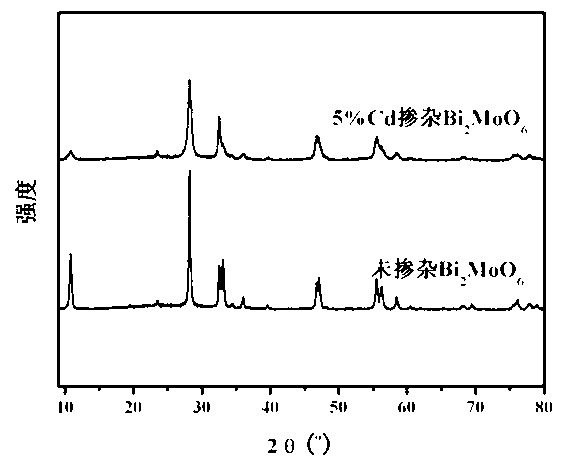

[0020] 3.1813 g Bi(NO 3 ) 3 ·5H 2 O and 0.5790 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was added to the polytetrafluoroethylene reaction kettle, and 25 ml of ethylene glycol solvent was added, and the reaction kettle was placed on a magnetic stirrer and stirred for 30 min, and the pH was adjusted with ammonia water with a mass fraction of about 5% while stirring. 9. After continuing to stir for 30 minutes, put the reactor in a ceramic lining and place it in a microwave reactor with a power of 1000 W, and react at 160°C for 1.5 hours. After the reaction is completed and cooled to room temperature, remove the The mixture was taken out and centrifuged, and the obtained pale yellow precipitate was washed several times with distilled water and absolute ethanol, dried at 60° C., and then ground to obtain a visible photocatalyst of bismuth molybdate.

Embodiment 2

[0022] 3.1018 g Bi(NO 3 ) 3 ·5H 2 O and 0.5790 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was added to the reaction kettle of polytetrafluoroethylene, 25 ml of ethylene glycol solvent was added, and then 0.0374 g of CdCl was added to the reaction kettle 2 2.5H 2 O, place the reaction kettle on a magnetic stirrer and stir for 30 minutes, adjust the pH to about 9 with ammonia water with a mass fraction of about 5% while stirring, continue stirring for 30 minutes, put the reaction kettle in a ceramic outer lining and Place in a microwave reactor with a power of 1000 W, and react at 160°C for 1.5 h. After the reaction is completed and cooled to room temperature, the mixture in the reactor is taken out and centrifuged, and the obtained pale yellow precipitate is washed with distilled water and absolute ethanol for several After drying at 60°C, grinding was done to obtain 2.5% Cd-doped bismuth molybdate visible photocatalyst.

Embodiment 3

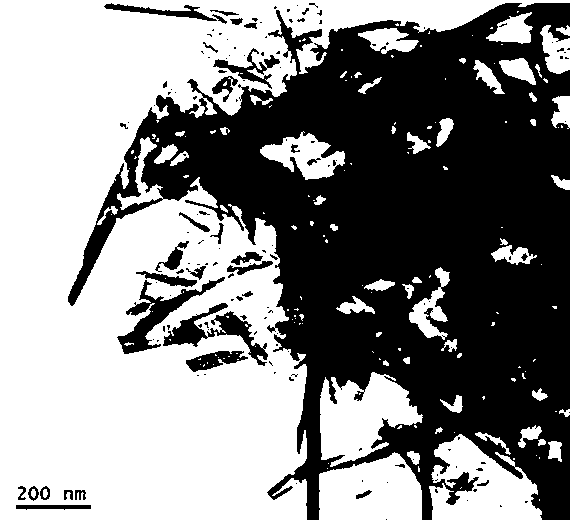

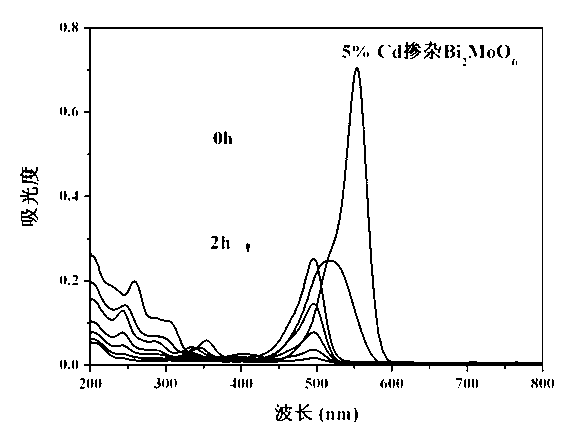

[0024] 3.0222 g Bi(NO 3 ) 3 ·5H 2 O and 0.5790 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was added to the reaction kettle of polytetrafluoroethylene, 25 ml of ethylene glycol solvent was added, and then 0.0749 g of CdCl was added to the reaction kettle 2 2.5H 2 O, place the reaction kettle on a magnetic stirrer and stir for 30 minutes, adjust the pH to about 9 with ammonia water with a mass fraction of about 5% while stirring, and continue stirring for 30 minutes, then put the reaction kettle in a ceramic outer lining and Place in a microwave reactor with a power of 1000 W, and react at 160°C for 1.5 h. After the reaction is completed and cooled to room temperature, the mixture in the reactor is taken out and centrifuged, and the obtained pale yellow precipitate is washed with distilled water and absolute ethanol for several After drying at 60°C, grinding was done to obtain 5% Cd-doped bismuth molybdate visible photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com