Preparation method of composite zeolite with core/shell structure

A technology of composite zeolite and core-shell structure, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc. Difficulties and other problems, to achieve the effect of simplifying the synthesis steps, improving thermal and hydrothermal stability, and shortening the transfer distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

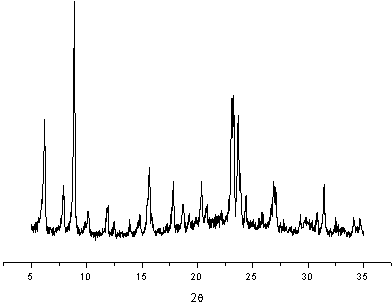

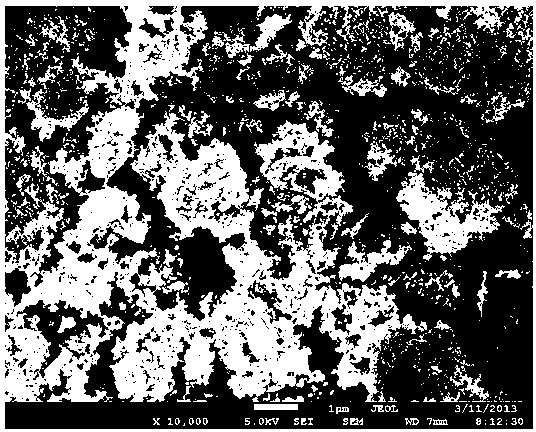

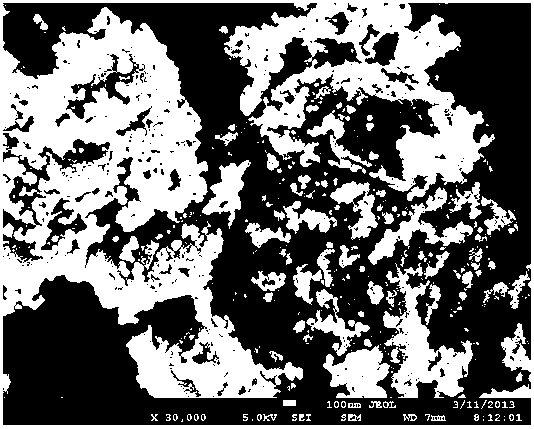

[0012] At room temperature, add 10g of high-silicon Y-type zeolite with a silicon-aluminum atomic ratio of 5, 0.8g of sodium hydroxide, 9g of tetraethylammonium bromide and 3g of ammonia water into 90g of deionized water, stir well, and then Slowly add 24g of silica sol with a mass percentage of 40% and mix evenly, then move it into a stainless steel reaction kettle, crystallize at 180°C for 72h, then cool it to room temperature with tap water, wash the product with distilled water until it is neutral, and filter it at 100°C ℃ drying in an oven for 12 hours, and then calcining in a muffle furnace at 550 ℃ for 6 hours under the condition of ventilation. Combined with XRD and SEM analysis, it shows that the obtained sample is a high-silicon Y-type zeolite as the nucleus, nano-polycrystalline ZSM -5 zeolite is the core / shell compound zeolite shell, and the EDS analysis shows that the silicon-aluminum atomic ratio of ZSM-5 is 15.

Embodiment approach 2

[0014] At room temperature, add 5 g of high-silicon Y-type zeolite with a silicon-aluminum atomic ratio of 2.5, 0.4 g of sodium hydroxide, and 2 g of tetrapropylammonium bromide into 80 g of deionized water. After stirring evenly, slowly drop Add 30g of silica sol with a mass percentage of 20% and mix evenly, move it into a stainless steel reaction kettle, crystallize at 170°C for 28h, then cool it to room temperature with tap water, wash the product with distilled water until it is neutral, filter it, and put it in a 100°C Dry it in an oven for 12 hours, then bake it in a muffle furnace at 550°C for 6 hours under the condition of air ventilation. Combined with XRD and SEM analysis, it shows that the obtained sample is a nano-polycrystalline ZSM-5 with high silicon Y-type zeolite as the nucleus. The zeolite is a core / shell type composite zeolite, and the EDS analysis shows that the silicon-aluminum atomic ratio of ZSM-5 is 20.

Embodiment approach 3

[0016] At room temperature, add 20g of high-silicon Y-type zeolite with a silicon-aluminum atomic ratio of 10, 1g of sodium hydroxide, and 3.7g of ethylenediamine into 100g of deionized water. After stirring evenly, slowly add 20g of After mixing evenly with 40% silica sol, move it into a stainless steel reaction kettle, crystallize at 160°C for 24h, then cool it to room temperature with tap water, wash the product with distilled water until neutral, filter, and dry in an oven at 100°C for 12h , in a muffle furnace at 550 ° C, roasted under the condition of air for 6 hours, combined with XRD and SEM analysis shows that the obtained sample is a high-silicon Y-type zeolite as the core, with nano-polycrystalline ZSM-5 zeolite as the shell Core / shell type composite zeolite, EDS analysis shows that the atomic ratio of silicon to aluminum of ZSM-5 is 25.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com