Preparation method of zirconium oxide-silicon oxide composite aerogel

A composite airgel and silicon oxide technology, which is applied in zirconia, chemical instruments and methods, silicon compounds, etc., can solve problems such as less research, and achieve good high temperature stability and low thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of zirconia-silicon oxide composite airgel, the zirconium alkoxide is selected from zirconium n-propoxide, the siloxane is selected from ethyl orthosilicate, the alcohol solvent is selected from ethanol, and the aging solution is the volume ratio of absolute ethanol:orthosilicon A mixture of ethyl acetate = 1:0.25, the drying medium is absolute ethanol, the molar ratio of siloxane: zirconium alkoxide = 1:0.11, the concentration of zirconium alkoxide and siloxane in the zirconia-silica composite sol The sum is 0.25mol / L. Follow the steps in order:

[0034] (1) Preparation of prehydrolyzed siloxane solution

[0035] At 4°C, dissolve ethyl orthosilicate in ethanol, stir and mix to obtain a 0.225mol / L mixed solution; according to mol Si: mol HNO 3 =1: 0.06 drops concentrated nitric acid with a mass concentration of 65-68%. According to mol Si: mol H 2 O=1:3, add deionized water dropwise, and continue to stir for 60 minutes to obtain a prehydrolyzed ...

Embodiment 2

[0046] A preparation method of zirconia-silica composite airgel, the zirconium alkoxide is selected from zirconium n-propoxide, the siloxane is selected from tetramethoxysilane, the alcohol solvent is selected from n-propanol, and the aging solution is anhydrous ethanol by volume ratio: Ethyl orthosilicate = 1:1 mixed solution, the drying medium is absolute ethanol, the molar ratio of siloxane: zirconium alkoxide = 1:1, zirconium alkoxide and siloxane in the zirconia-silica composite sol The sum of the concentrations is 0.5mol / L. Follow the steps in order:

[0047] (1) Preparation of prehydrolyzed siloxane solution

[0048] At 20°C, dissolve tetramethoxysilane in n-propanol, stir and mix to obtain a 0.25mol / L mixed solution; according to mol Si: mol HNO 3 =1: 0.09 drops concentrated nitric acid with a mass concentration of 65-68%. According to mol Si: mol H 2 O=1:2.5 Add distilled water dropwise, and continue stirring for 30 minutes to obtain a prehydrolyzed siloxane solut...

Embodiment 3

[0059] A preparation method of zirconia-silicon oxide composite airgel, zirconium alkoxide is selected from zirconium isopropoxide, siloxane is selected from methyltriethoxysilane, alcohol solvent is selected from isopropanol, and the aging solution is volume ratio anhydrous Ethanol: tetraethyl orthosilicate = 1:2 mixture, the drying medium is isopropanol, the molar ratio of siloxane: zirconium alkoxide = 1:1, zirconium alkoxide and silicon in the zirconia-silica composite sol The sum of the concentrations of oxanes is 1.0 mol / L. Follow the steps in order:

[0060] (1) Preparation of prehydrolyzed siloxane solution

[0061] At 20°C, dissolve methyl triethoxy silicon in isopropanol, stir and mix to obtain a 0.5mol / L mixed solution; according to molSi:mol HNO 3 =1: 0.09 drops concentrated nitric acid with a mass concentration of 65-68%. According to mol Si: mol H 2 O=1:2.5 Add distilled water dropwise, and continue stirring for 30 minutes to obtain a prehydrolyzed siloxane s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

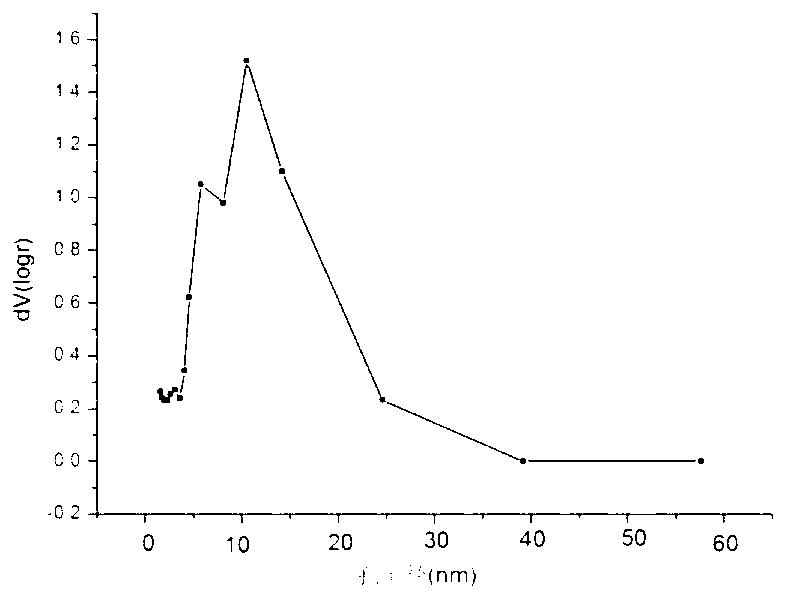

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com