Method for controlling growth of P-type GaN low-flow dopant

A growth method and dopant technology, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of large damage, poor electrical conductivity, and increased volume, so as to reduce production costs and improve electrical conductivity , Improve the effect of crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

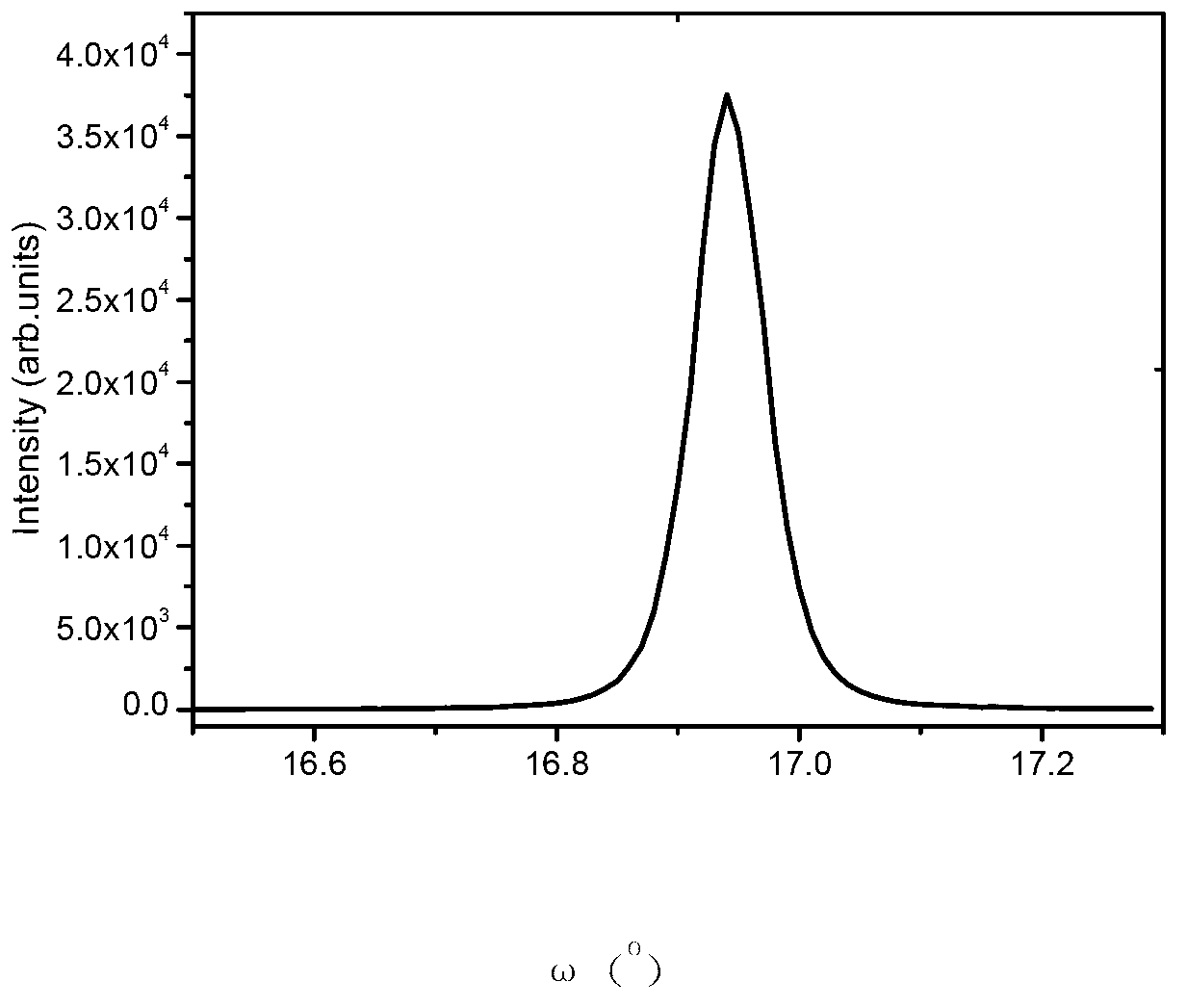

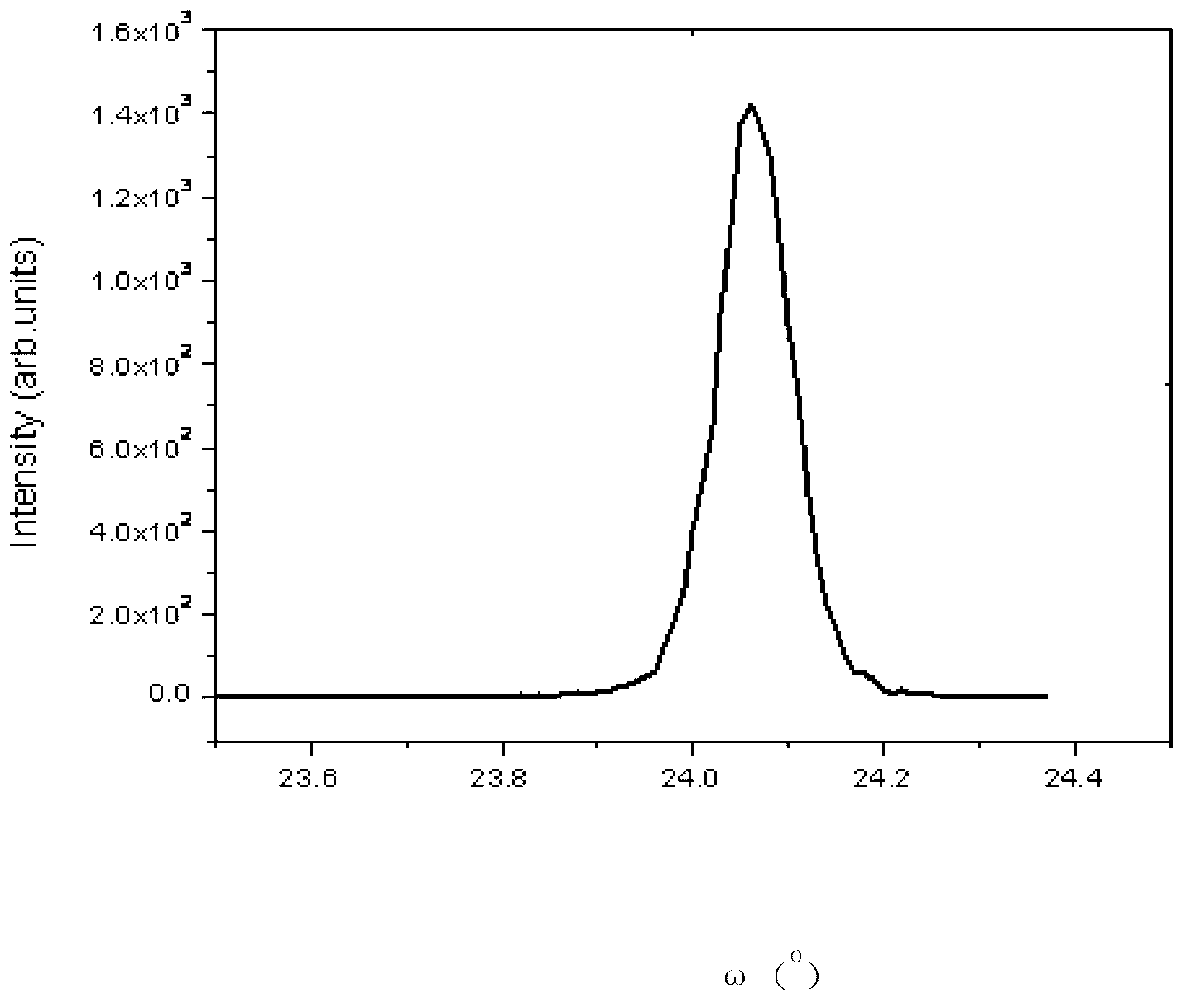

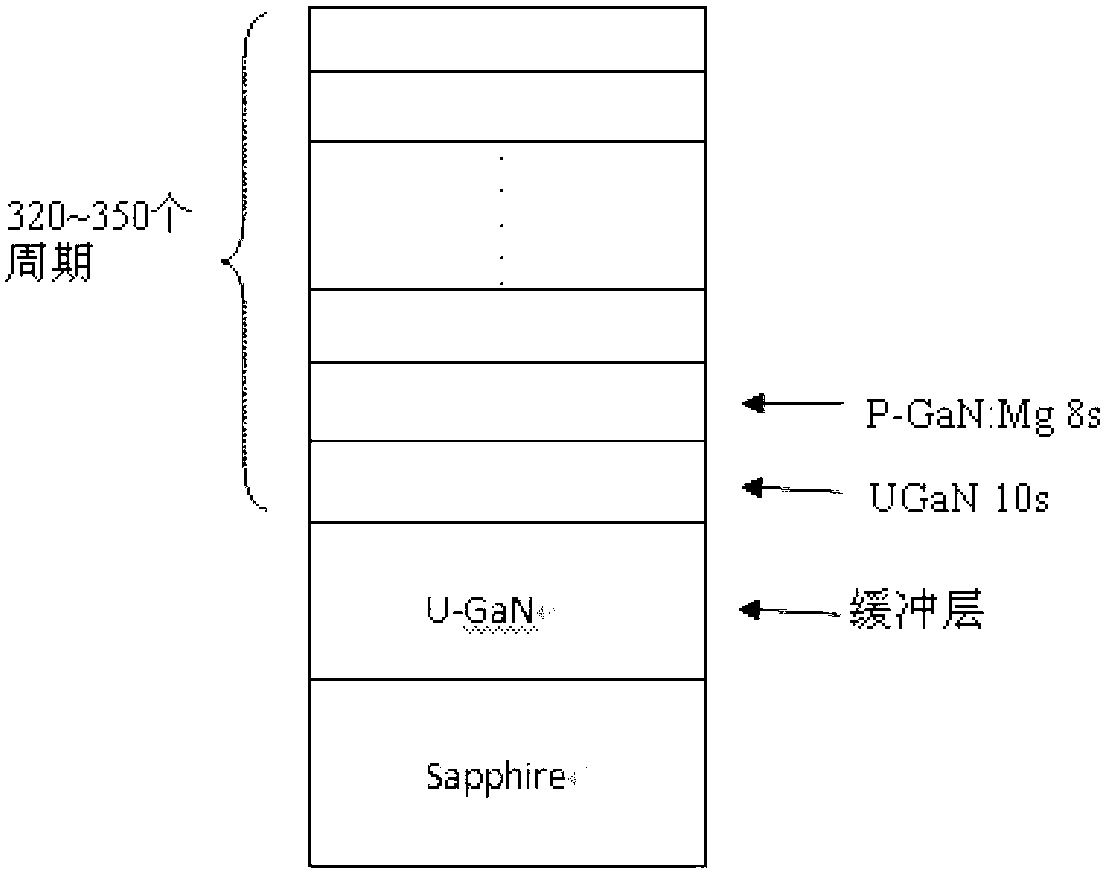

[0021] In order to make the present invention clearer, combined with figure 1 The present invention is further described in detail.

[0022] The method for growing P-type GaN material by MOCVD equipment provided by the present invention, its specific growth structure is as follows figure 1 As shown, the structure from bottom to top is: sapphire substrate, non-doped GaN buffer layer, and P-type GaN growth layer. The source materials for epitaxial growth are: TMGa and NH 3 as Ga source and N source respectively, CP 2 Mg acts as a Mg dopant. h 2 For the carrier gas. details as follows:

[0023] (1) Veeco D180 MOCVD equipment is used, and (0001) surface sapphire is selected as the substrate.

[0024] (2) Put the sapphire substrate into the MOCVD reaction chamber, 2 The chamber temperature was raised to 1100°C under atmosphere and held for three minutes to clean the substrate.

[0025] (3) Lower the temperature of the reaction chamber to 500°C, and epitaxially grow a low-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com