Preparation method of lithium iron phosphate/expanded graphite composite electrode material and preparation method of lithium ion capacitor made of material

A technology of expanded graphite and lithium iron phosphate, applied in the field of preparation of the lithium ion capacitor, can solve the problems of large environmental pollution, low safety performance, high cost, etc., and achieve the effects of process stability, cost saving of raw materials, and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

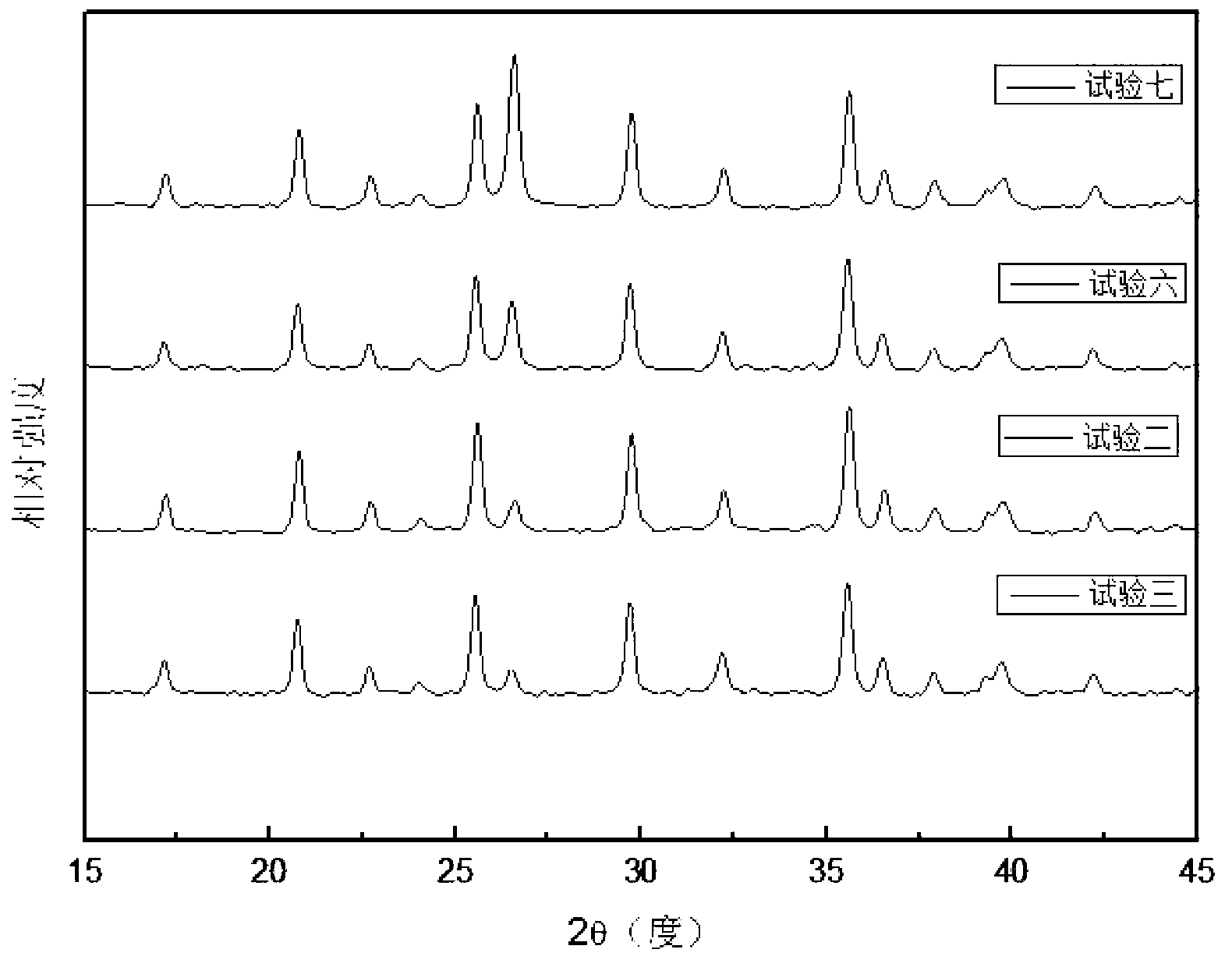

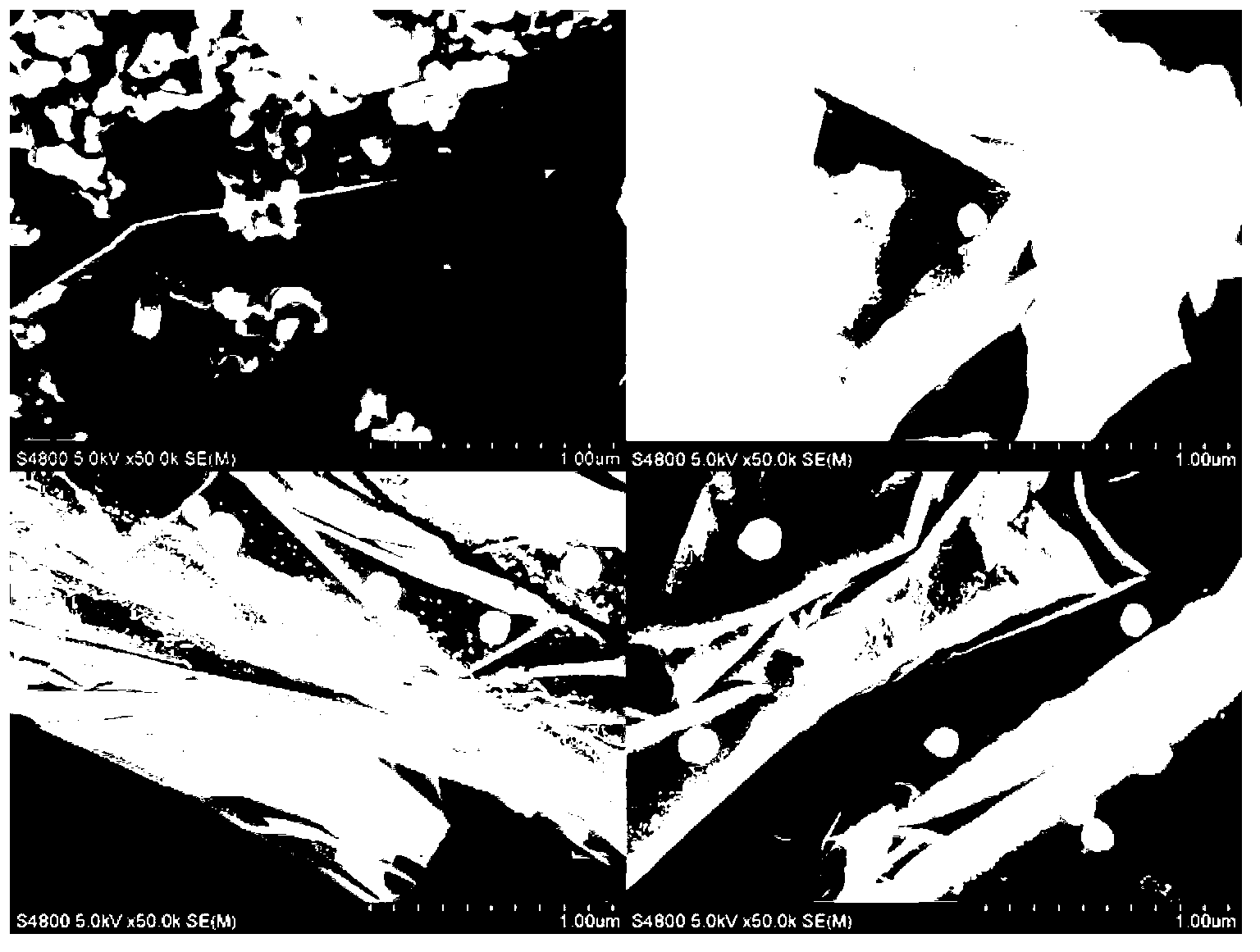

Examples

specific Embodiment approach 1

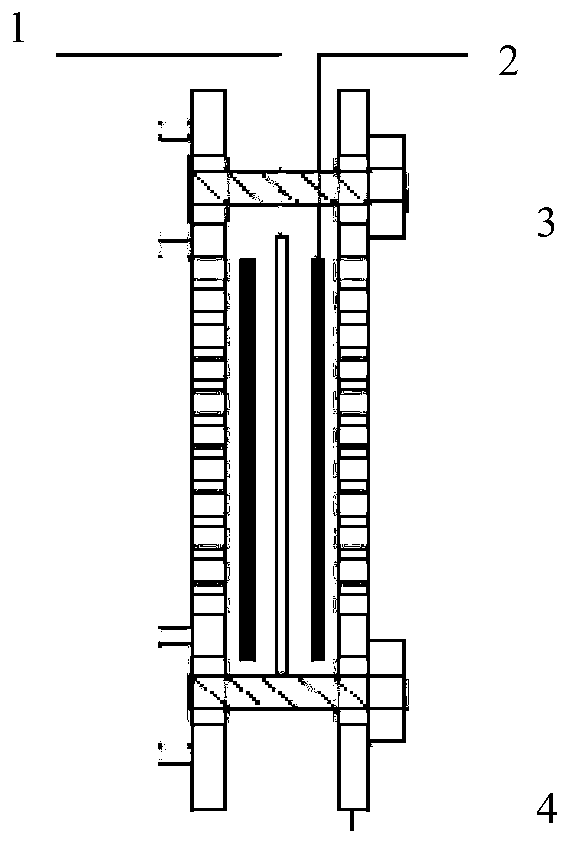

[0018] Specific embodiment one: the preparation method of the lithium iron phosphate / expanded graphite composite electrode material of the present embodiment is realized through the following steps:

[0019] 1. Dissolve phosphorus source, iron source and lithium source in a certain amount of H at a molar ratio of 1:1:1 2 In O, the lithium iron phosphate precursor was prepared by heating and stirring in a water bath at 45 °C. At the same time, the expandable graphite was expanded in a muffle furnace at 900 °C for 20 s. The lithium source is a common water-soluble lithium salt such as lithium chloride, lithium hydroxide, lithium dihydrogen phosphate, etc.; the iron source is a water-soluble iron salt such as iron citrate, iron ammonium citrate, etc.; the phosphorus source is water-soluble phosphorus Salts such as lithium dihydrogen phosphate, ammonium dihydrogen phosphate, etc.

[0020] 2. Mix the expanded graphite with the lithium iron phosphate precursor, stir mechanically at...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment is different from Embodiment 1 in that: in step 1, the source of phosphorus and lithium is lithium dihydrogen phosphate; the source of iron is iron citrate. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0024] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass fraction of expanded graphite in step 2 is 2.5%-15%. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com