Polydimethylsiloxane array micropore film preparation method

A technology of polydimethylsiloxane and dimethylsiloxane, which is applied in the field of microelectromechanical manufacturing systems (MEMS), can solve the problems of complex preparation steps, small film size, and restrictions on wide application, and achieve simple manufacturing methods , Guarantee the integrity and ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

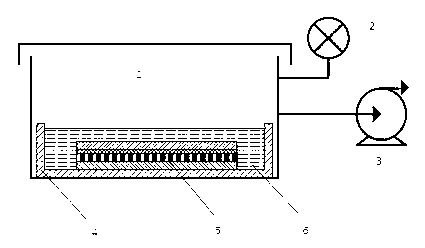

[0026] Below in conjunction with accompanying drawing, specify the manufacture method that device of the present invention implements array microporous film:

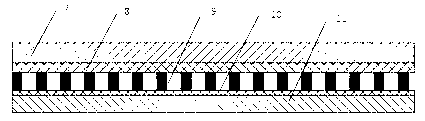

[0027] Step 1. Pretreatment of the base 11 under the mold. Spin-coat a layer of SU-8-2005 photoresist with a thickness of 5 microns on the surface of the lower substrate 11 of the mold by using a glue leveling table, and then perform pre-baking, full exposure, and post-baking to form a pre-treated thin glue layer 10 to improve the SU-8 micron thickness. The binding force between the column and the substrate;

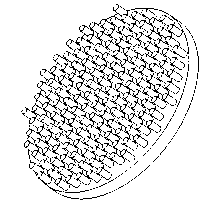

[0028] Step 2, preparation of microcolumn structure. Spin-coat the SU-8-2100 photoresist on the surface of the lower substrate 11 of the mold that has been pretreated in step 1, level the glue on the leveling table, and then perform pre-baking, mask exposure, post-baking and development to form SU- 8 Micro-group pillar structures 9, such as image 3 shown;

[0029] Step 3, making the micro-column channel mold....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com