Method for quickly preparing drying agent array for protein crystallization

A protein crystallization and desiccant technology, applied in the field of protein crystallization, can solve the problems of time-consuming and labor-intensive silica gel desiccant, inability to realize popularization and application, and achieve the effect of improving production efficiency, improving success rate, and realizing popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Screening of lysozyme crystallization conditions.

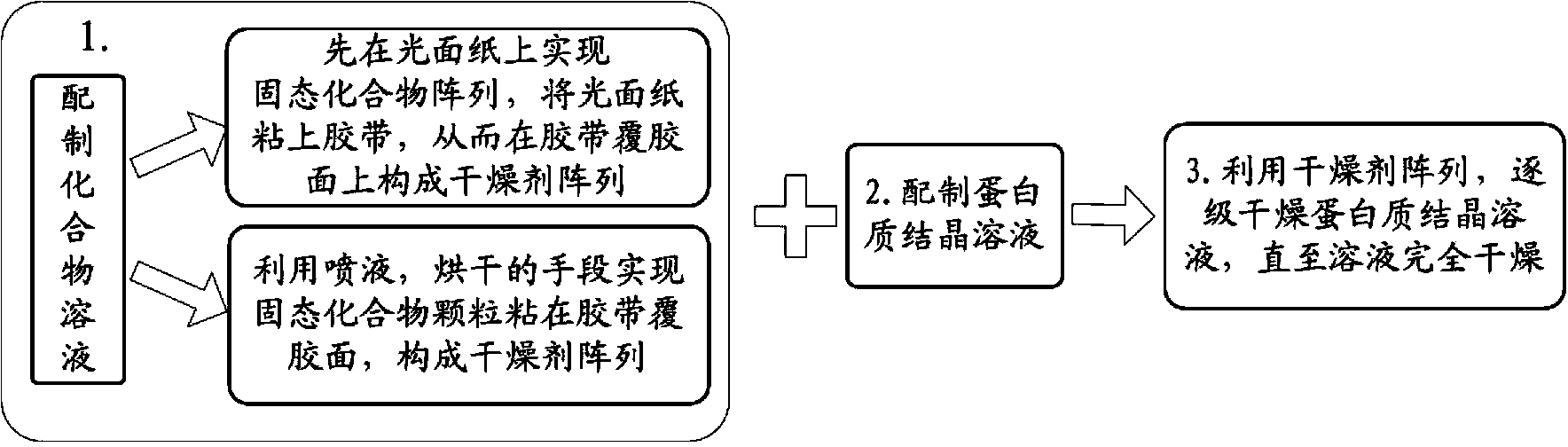

[0024] 1. Preparation of desiccant array

[0025] Replace the ink in the inkjet printer with a cobalt chloride solution with a concentration of 100mg / ml, set the shape of the printed particles to be circular on the computer, and have a diameter of 0.5mm to form a 12×8 array with a particle spacing of 9mm. A solution of cobalt chloride was printed onto the glossy side of glossy paper, forming an array of solid cobalt chloride particles. Then stick the transparent sealing tape with glue on one side to the smooth surface of the glossy paper, tear off the tape from the glossy paper, and the array of solid desiccant particles adheres to the glued surface of the tape.

[0026] 2. Preparation of lysozyme crystallization solution

[0027] Lysozyme recrystallized six times (Japan Seikagaku Company, product number 100940) was dissolved in pH 7.00, 0.025mol / L HEPES-Na buffer to prepare a lysozyme solution with a conc...

Embodiment 2

[0031] Example 2: Screening of sweet protein crystallization conditions.

[0032] 1. Preparation of desiccant array

[0033] Use an electric pipette to pipette the mixed solution of 20 mg / ml cobalt chloride and 10 mg / ml aluminum chloride onto the smooth surface of the glossy paper to form a 12 × 8 array with a particle spacing of 9 mm and a droplet volume of 0.5 μl, dried, and then glued to the smooth surface of the glossy paper with a transparent sealing tape covered with glue on one side, and the tape was torn off from the glossy paper, and the array of solid desiccant particles adhered to the glued surface of the tape.

[0034] 2. Preparation of sweet protein crystallization solution

[0035] Sweet protein (Sigma, USA, product number T7638) was dissolved in pH 7.00, 0.025 mol / L HEPES-Na buffer solution to prepare a sweet protein solution with a concentration of 5 mg / ml. Use the automatic pipetting system to index Hampton company product number HR2-144 TM The protein crysta...

Embodiment 3

[0039] Example 3: Screening of lactalbumin crystallization conditions.

[0040] 1. Preparation of desiccant array

[0041] Use an automatic pipetting system to pipette the magnesium chloride solution with a concentration of 30 mg / ml onto the smooth surface of the glossy paper to form a 12×8 array with a particle spacing of 9 mm and a droplet volume of 0.3 μl. Adhesive transparent sealing tape sticks to the smooth surface of the glossy paper, and the tape is torn off from the glossy paper, and the array of solid desiccant particles adheres to the glued surface of the tape.

[0042] 2. Preparation of lactalbumin crystallization solution

[0043] Dissolve lactalbumin (Sigma, USA, product number L5385) in pH 7.00, 0.025mol / L HEPES-Na buffer to prepare a lactalbumin solution with a concentration of 10mg / ml. Use the automatic pipetting system to index Hampton company product number HR2-144 TM The protein crystallization reagents in the 96 crystallization kit were transferred to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com