Burkholderia sp. and method for fermentation synthesis of PHA by adopting the same

A technology of Burkholderia and bacterium Burkholderia, applied to a strain of Burkholderia and the field of fermenting and synthesizing PHA with this bacterium, can solve the problem that the economy cannot be compared with petroleum-based materials Counterbalance, high preparation cost and other problems, to achieve the effect of reducing production cost, optimizing fermentation conditions and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Screening and isolation of Burkholderia sp. CG-01

[0023] The experimental materials come from the root soil of clove trees next to the biological building of Nankai University in Tianjin.

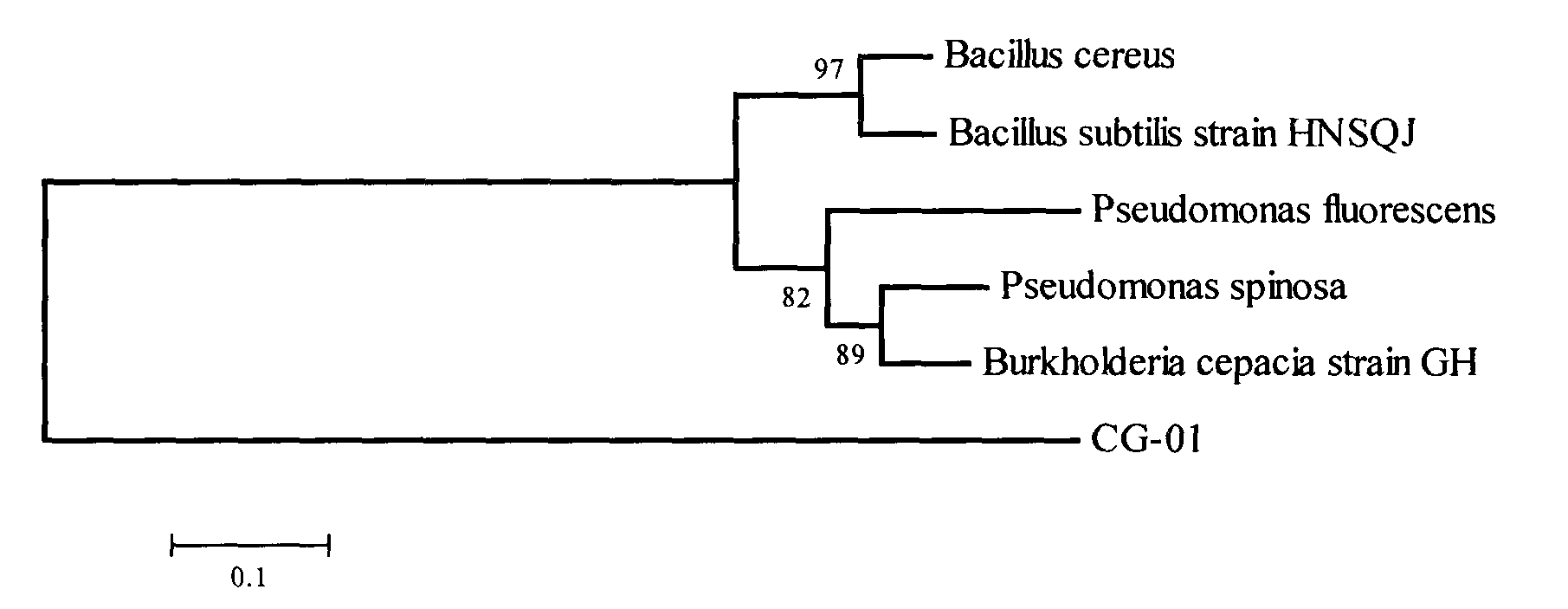

[0024] Concrete implementation steps are as follows: take 1g soil sample, add 99ml sterile normal saline (10 -2 ), stir for 20 minutes, make it fully mixed, let it stand for a while, take the supernatant, dilute it with normal saline in a 10-fold gradient, and dilute it to 10 -3 -10 -5 And spread it on the solid screening separation medium plate, culture at 30°C for 48 hours, observe under 312nm ultraviolet light, mark the colony with orange-red fluorescence, pick the colony, and streak on the solid screening separation medium plate to purify , cultivated at 30°C for 24 hours, picked orange-red colonies and stored them in glycerol tubes. After 16S rDNA gene sequence analysis and BIOLOG identification, it was determined that the bacterium belonged to the genus Burkhol...

Embodiment 2

[0025] Example 2 Fermentation of Burkholderia sp. CG-01, CGMCC No.7329 to synthesize PHA

[0026] The specific steps are as follows: Inoculate the strains into 5ml seed medium, culture on a shaking table at 30°C, and rotate at 120rpm, after 11 hours of cultivation, inoculate 5% of the inoculum into 200ml fermentation synthetic medium, and shake on a shaking table at 30°C Cultivate at a rotation speed of 150rpm. After 24 hours of cultivation, the bacterial liquid was centrifuged, washed with phosphate buffer solution, and centrifuged again. All the centrifuged bacteria were transferred to 200ml of PHA fermentation medium, wherein the glucose concentration was 10g / L, the rotation speed was 180rpm, and 30 Shake flask fermentation at ℃ for 36 hours; centrifuge the fermentation broth, discard the supernatant, collect the bacteria and freeze-dry; transfer the dried bacteria into a 100ml Erlenmeyer flask, add chloroform at 25ml / g and stir for 48 hours, filter to remove the bacteria ...

Embodiment 3

[0027] Example 3 Fermentation of Burkholderia sp. CG-01, CGMCC No.7329 to synthesize PHA

[0028] The specific steps are as follows: Inoculate the strains into 5ml seed medium, culture on a shaking table at 30°C with a rotation speed of 120rpm, after 12 hours of cultivation, inoculate 5% of the inoculum into 200ml fermentation synthetic medium, and shake on a shaking table at 30°C Cultivate at a rotation speed of 150rpm. After 24 hours of cultivation, the bacteria liquid is centrifuged, washed with phosphate buffer solution, and centrifuged again. After centrifugation, all the bacteria are transferred into 200ml of PHA fermentation medium with a glucose concentration of 15g / L and a rotation speed of 150rpm at 30°C. Ferment in a shaker flask for 48 hours; centrifuge the fermentation broth, discard the supernatant, collect the bacteria and freeze-dry; transfer the dried bacteria to a 100ml Erlenmeyer flask, add chloroform at 25ml / g and stir for 48 hours, filter to remove the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com